Machine tool health state rapid checking method

A technology of health status and rapid inspection, applied in computer control, program control, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

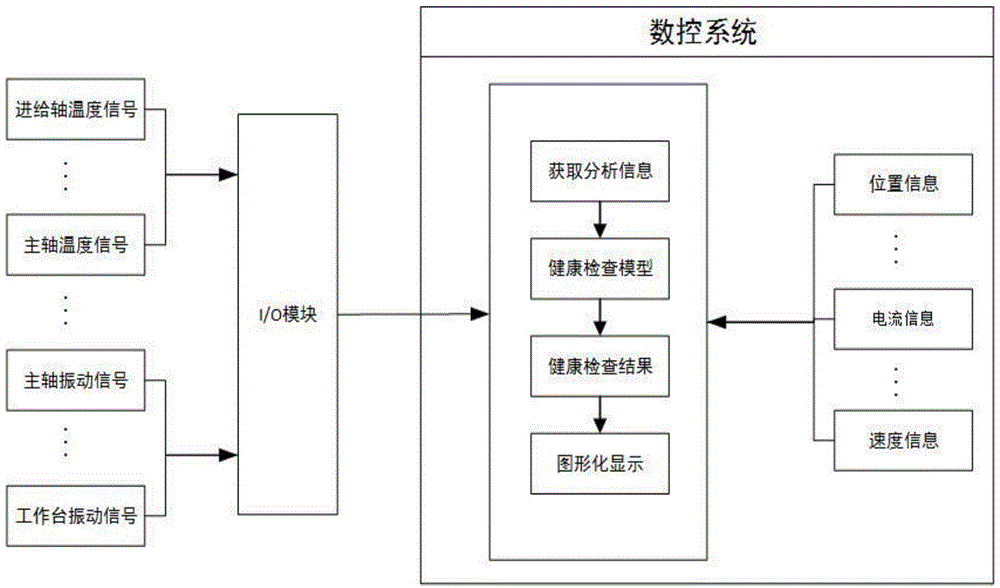

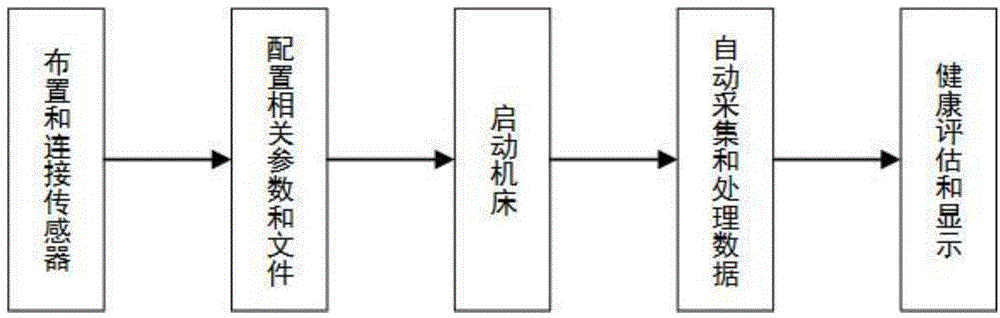

[0026] In order to make the purpose, implementation steps and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0027] In this embodiment, the monitoring objects are the axis current (spindle, X axis, Y axis), axis following error (X axis, Y axis), and vibration of the spindle and worktable of the CNC machine tool.

[0028] Step 1: According to the inspection object, place a vibration sensor in the two directions perpendicular to the bearing seat of the main shaft and in the vertical direction of the workbench, and place a temperature sensor in the bearing seat and the nut seat near the motor end of each shaft, and place a temperature sensor in the two directions of the main shaft Put temperature sensors into the end bearing housings respectively, and connect all temperature sensors to the HIO-1075 board unit of the CNC system I / O module, and connect all vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com