Mining while-drilling type borehole track detection method and system and drill rod

A detection method and drill pipe technology, applied in the field of drill pipes and systems, can solve problems such as inability to detect online, and achieve the effects of saving battery power, optimizing hardware resources, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

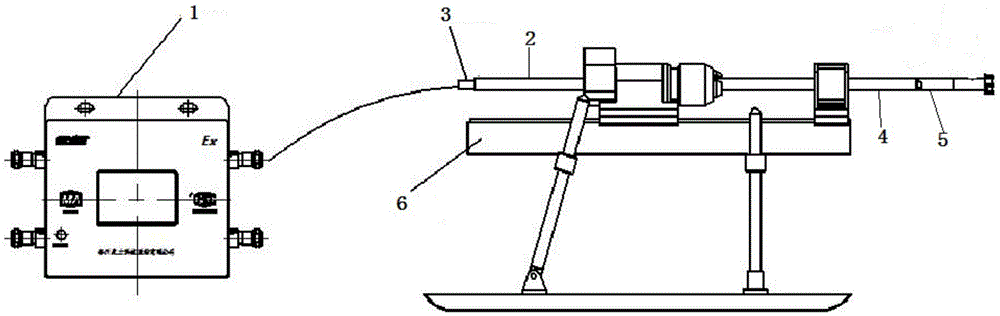

[0028] Embodiment of Drilling While Drilling Track Detection System for Mine

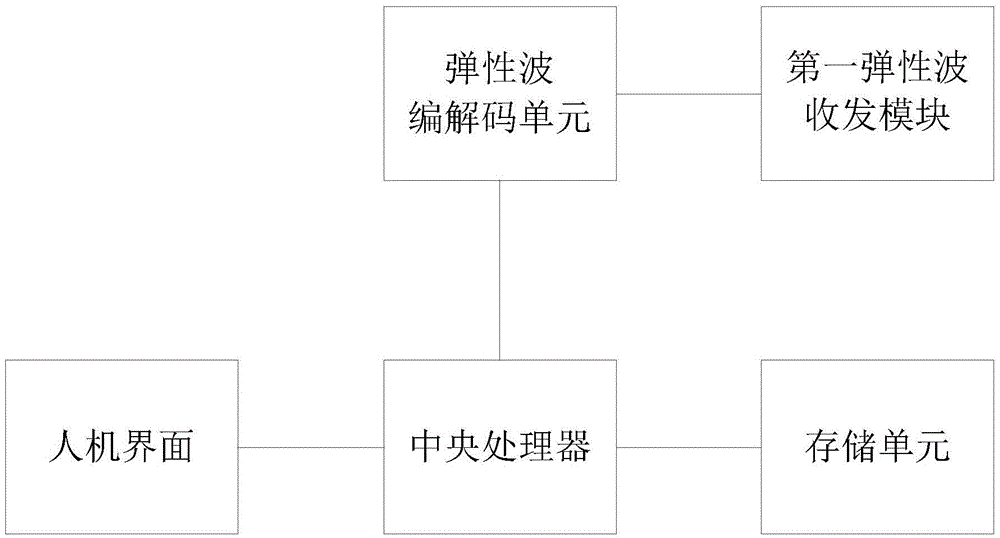

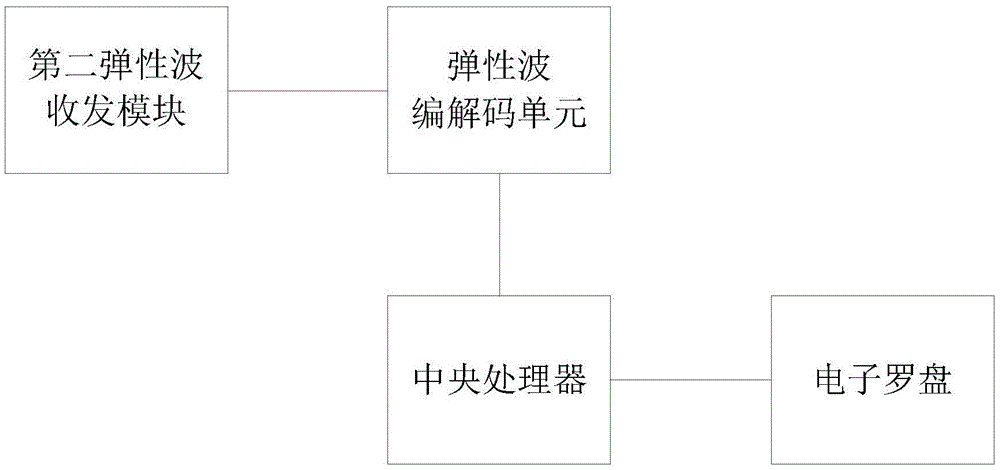

[0029] A kind of drilling-while-drilling drilling track detection system provided by the present invention, such as figure 1 Shown includes a measuring host 1 and a drill pipe 2, and the measuring host also drives and connects a first elastic wave transceiver module 3 for receiving and sending elastic waves. Such as figure 2 As shown, the measurement host includes a central processing unit, a man-machine interface, a storage unit, and a codec unit. The man-machine interface, the storage unit, and the codec unit are all connected to the central processor, and the codec unit also drives and connects the The first elastic wave transceiver module 3 that sends the elastic wave; the codec unit is used to decode the elastic wave received by the first elastic wave transceiver module and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com