Cable trench operation and maintenance monitoring system

A monitoring system and cable trench technology, applied in the field of electric power engineering, can solve the problems of high power consumption, inability to realize online persistent monitoring, and inability to form big data, etc., achieve low power consumption and realize the effect of long-term online collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

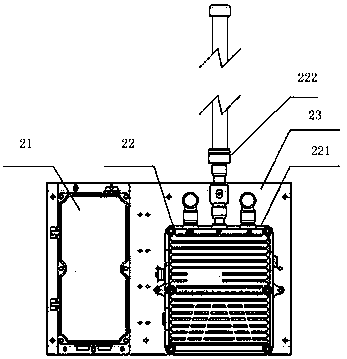

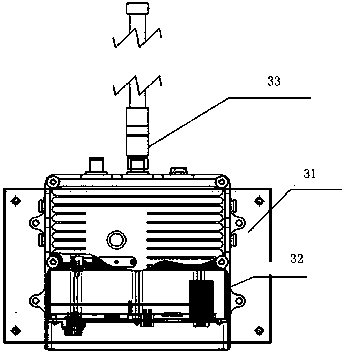

[0018] The core content of this patent is to use the magic knot sensor to collect the volume concentration of combustible alkanes, hydrogen sulfide H2S gas and carbon monoxide gas, and further explain the specific implementation of the system.

[0019] An embodiment of a cable trench operation and maintenance monitoring system provided by the present invention will be described in detail below.

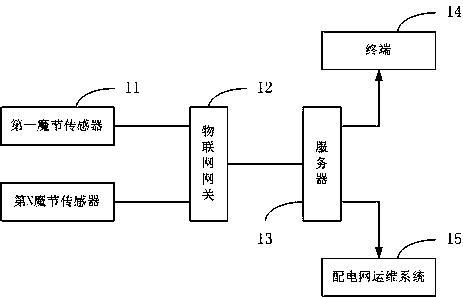

[0020] like figure 1 As shown, the embodiment of the present invention provides a cable trench operation and maintenance monitoring system, the system includes a first magic joint sensor 11, an Internet of Things gateway 12 connected to the first magic joint sensor 11, and a server 13 connected to the Internet of Things gateway 12 , a mobile terminal 14 connected to the server 13 and a power distribution network operation and maintenance system 15, wherein:

[0021] The first magic joint sensor 11 includes a temperature measuring probe, a gas probe, a smoke probe and a liquid level p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com