Damage monitoring and online maintenance system for metal material structure

A metal structure, damage monitoring technology, applied in the evaluation, positioning and online maintenance system, the damage monitoring and online maintenance system of metal material structure, the real-time measurement of metal structure parts damage, can solve the problems that are not suitable for traditional human maintenance, automation Low level of maintenance, slow maintenance and other problems, to achieve the effect of improving the degree of intelligence, safety and reliability, high degree of automation, and reducing the pressure of supply and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

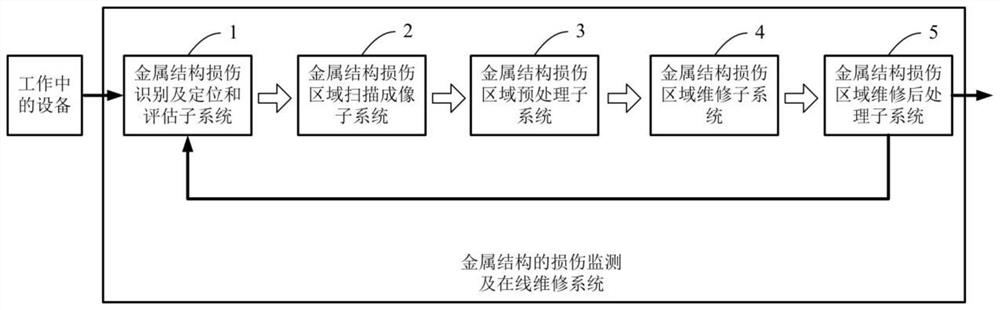

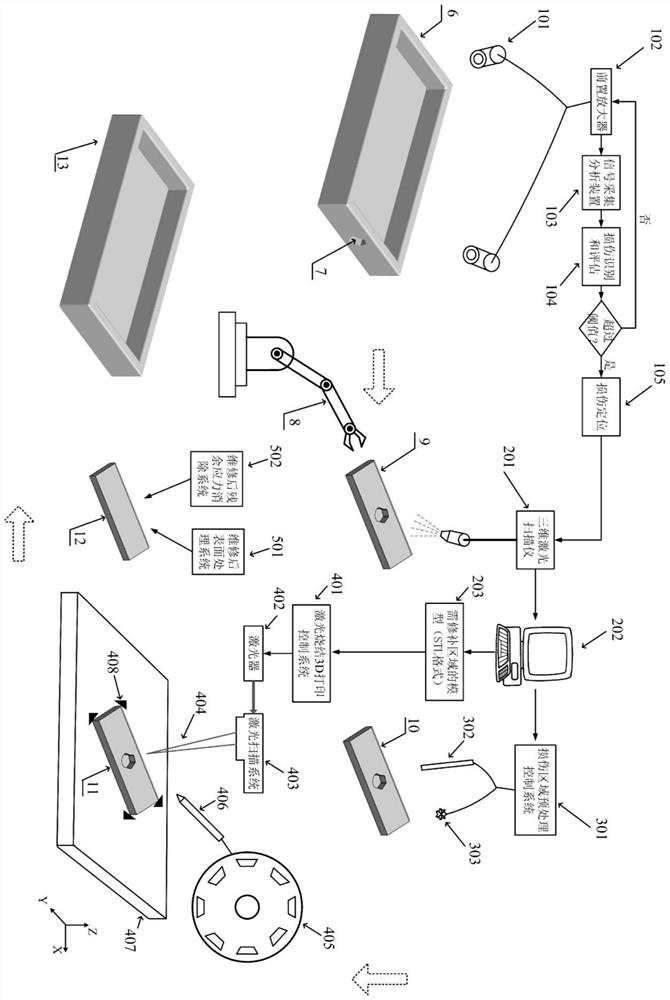

[0025] as attached figure 1 And attached figure 2As shown, a damage monitoring and on-line maintenance system for metal material structures of the present invention includes a metal structure damage identification, location and evaluation subsystem 1, a metal structure damage area scanning imaging subsystem 2, a metal structure damage area preprocessing subsystem 3, Metal structure damaged area maintenance subsystem 4, metal structure damaged area maintenance post-processing subsystem 5, damaged metal parts 6, damaged area 7, manipulator 8, metal structure to be repaired 9, pretreated metal structure 10, under repair Metal structure 11, repaired metal structure 12, and repaired metal parts 13; wherein, metal structure damage identification, location and evaluation subsystem 1 includes acoustic emission sensor 101, preamplifier 102, signal acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com