Method for shearing water gap and device for implementing method

A nozzle and water cutting technology, which is applied in the field of the nozzle method and the device for implementing the method, can solve the problems of prolonging the production cycle, complex mold structure, and large external dimensions, and achieves the advantages of reduced labor intensity, simple process, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

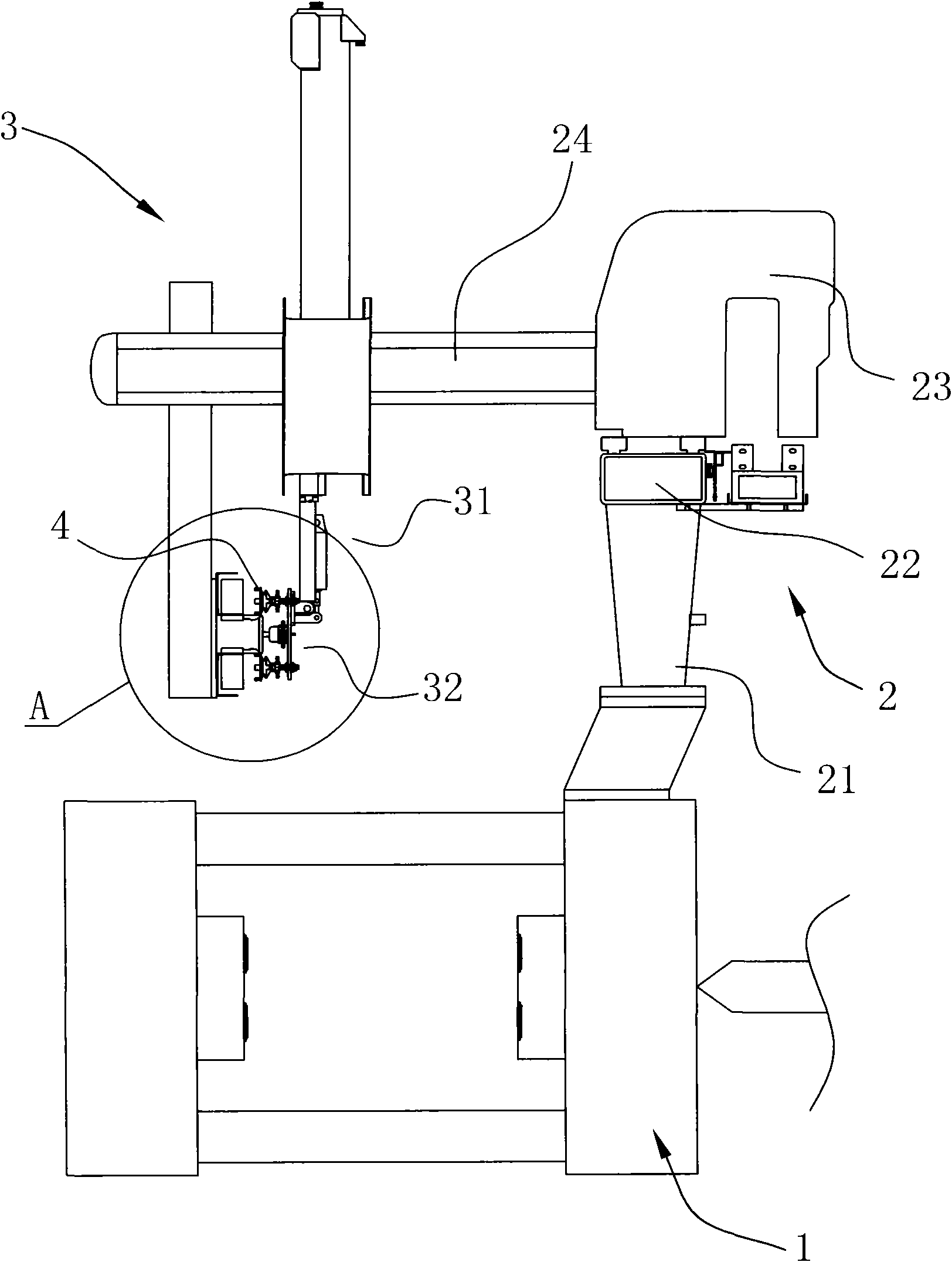

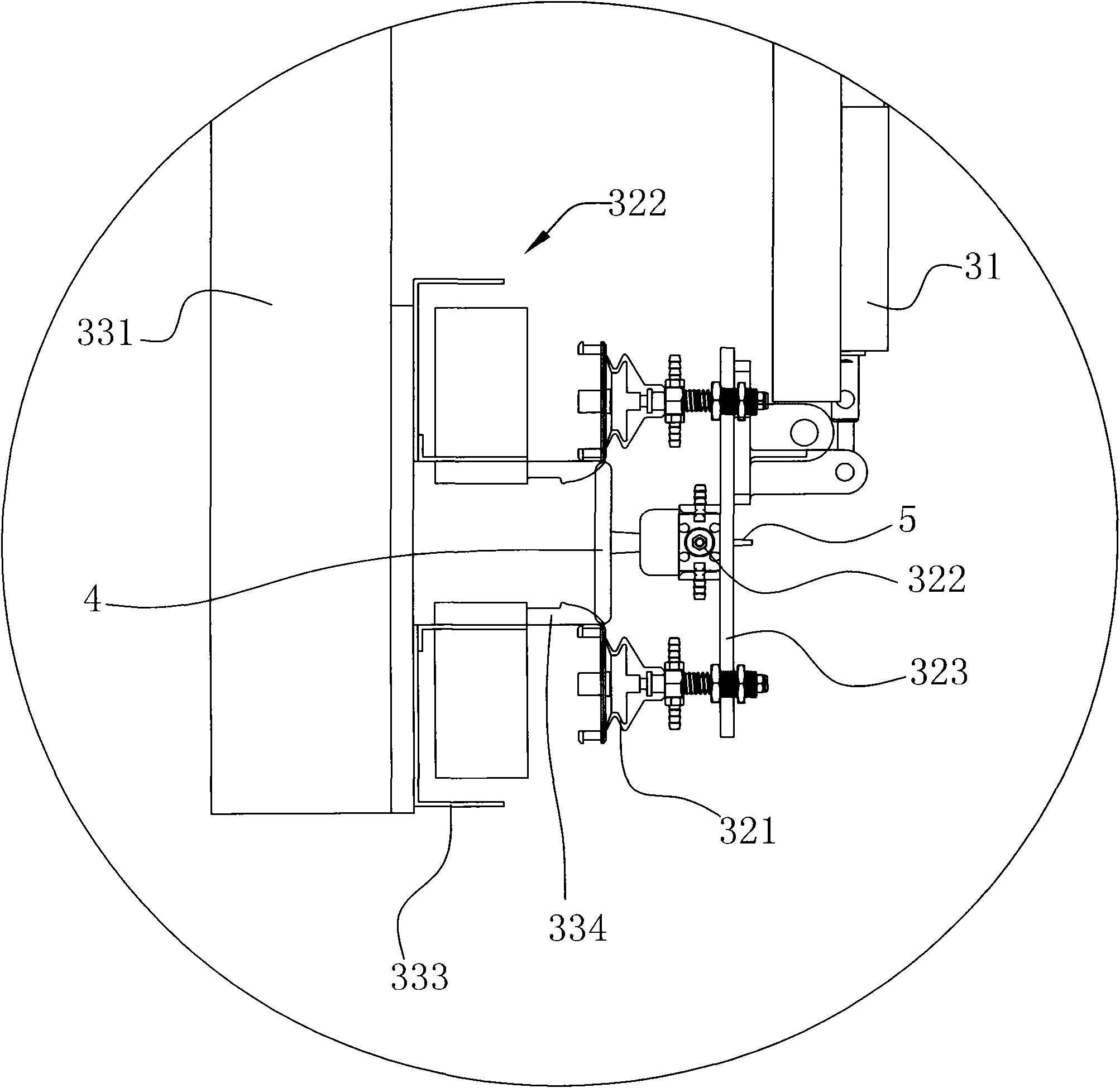

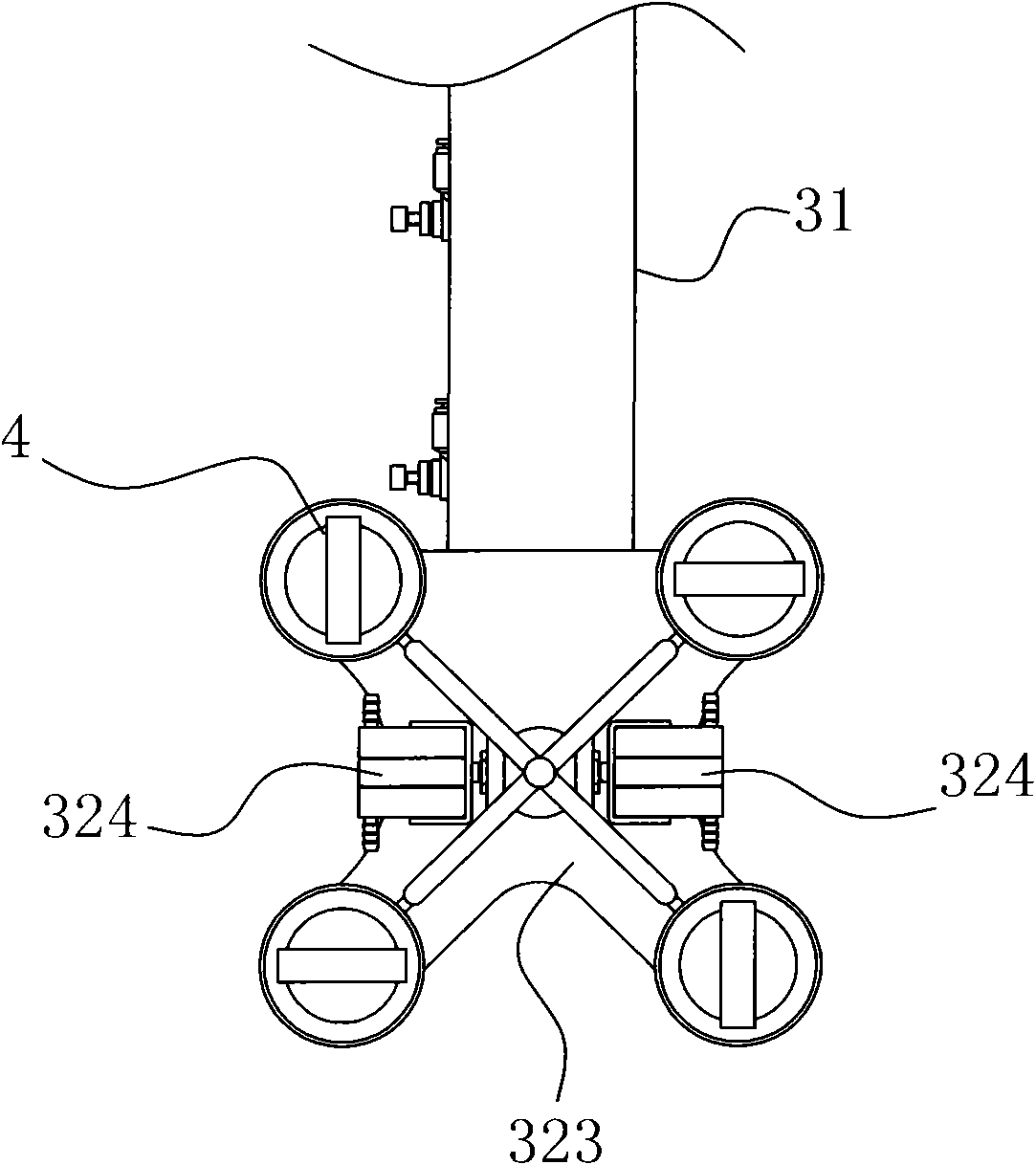

[0049] Example: see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a kind of scissors method, and it comprises the following steps:

[0050] (1) A frame 2 is arranged on one side of the injection molding machine 1, and one side of the frame 2 can extend to the top of the plastic mold on the injection molding machine 1;

[0051] (2) a material cutting device 3 is set, and the material cutting device 3 is movably arranged on the frame 2, and is used to take out the formed product 4 in the plastic mold, and cut off the material opening 5 of the formed product 4, and then placed in the finished product area;

[0052] (3) A control system is provided, which is connected to the cutting device 3 and controls its working state. The nozzle method provided by the present invention has the advantages of simple process, high speed and high efficiency, greatly reduces production man-hours and saves production costs;

[0053] Described step (1) spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com