Arc core-pulling device of die-casting mould

A core-pulling device and die-casting mold technology, applied in the core-pulling field of castings, can solve problems such as low dimensional accuracy of castings, increased production man-hours, and low production efficiency, and achieve the effects of shortening production man-hours, improving production efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

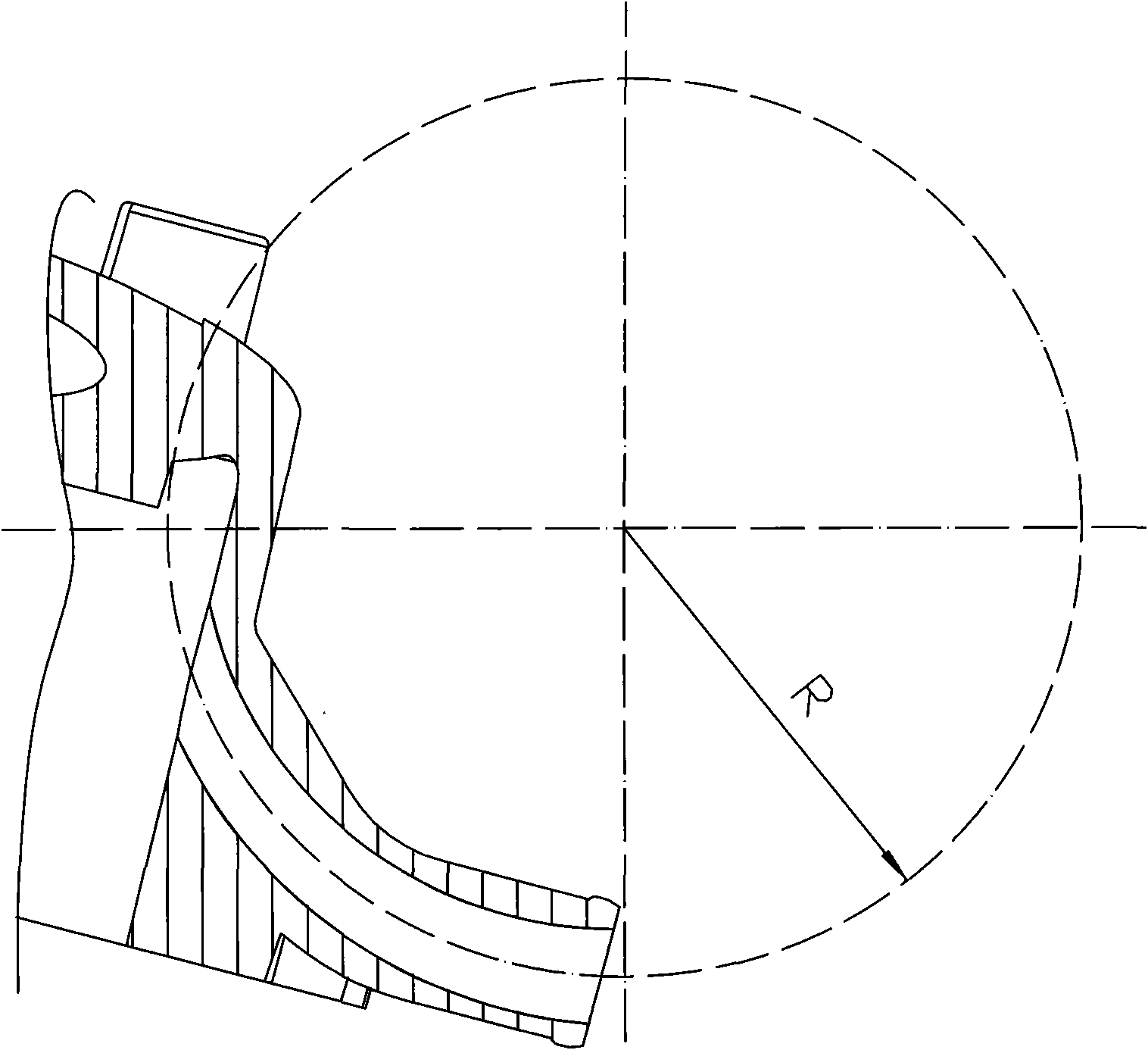

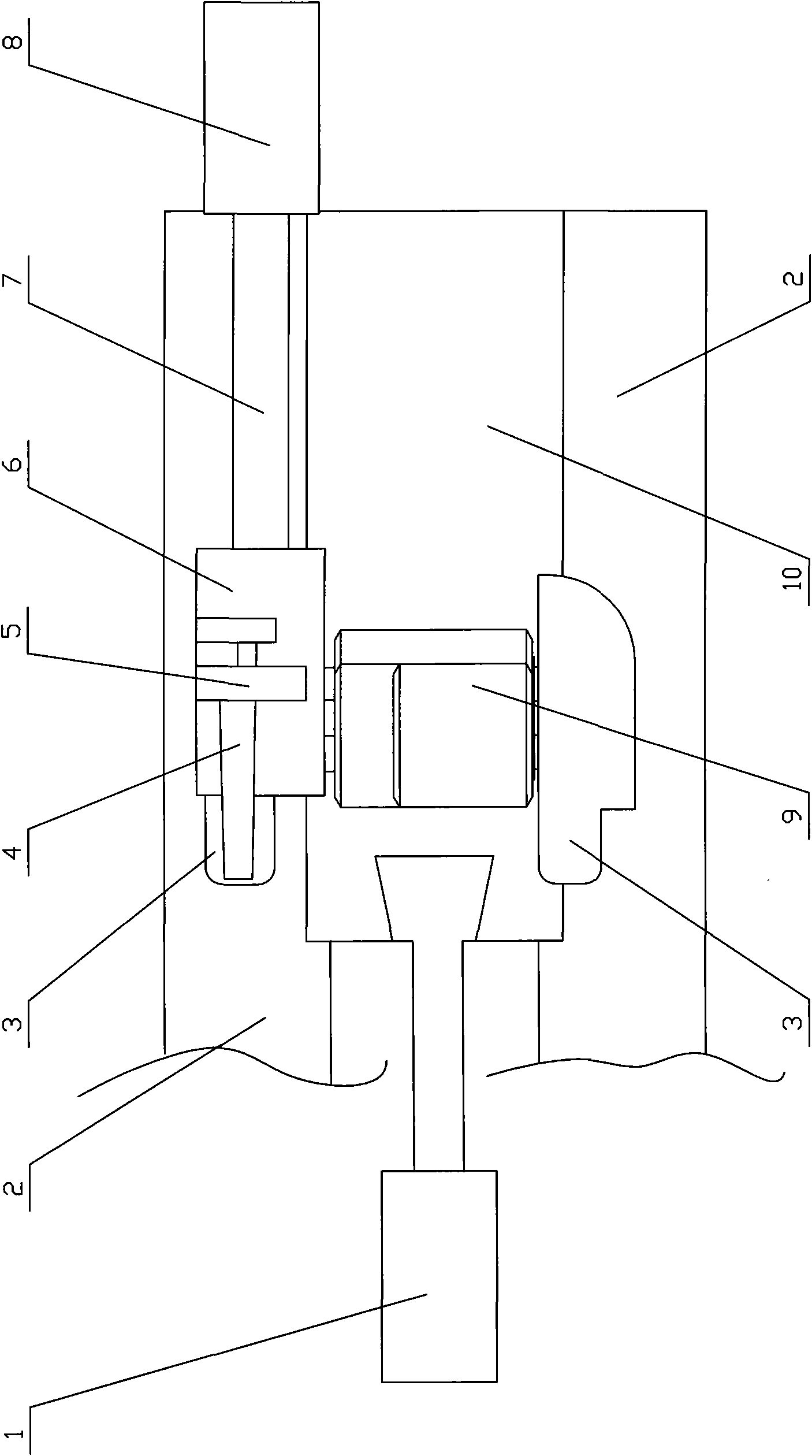

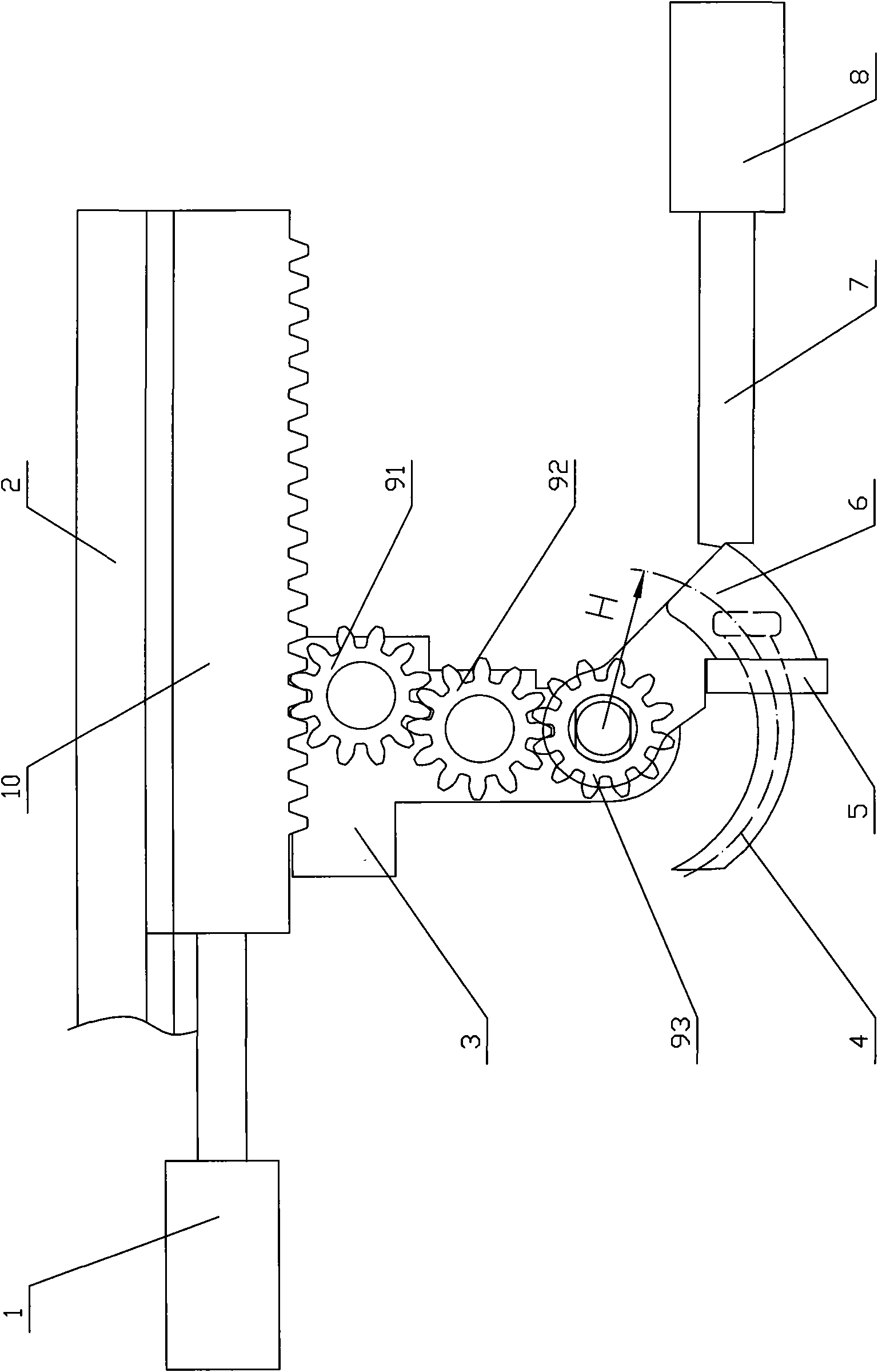

[0019] Depend on Figure 1 ~ Figure 3 The structural diagram of the arc core-pulling device of the die-casting mold shown shows that it includes a guide rail 2, a moving cylinder 1, a rack 10, a gear set 9 intermeshed on a gear seat 3, a connecting block 6, and a casting arc The circular arc slide block 4 that inner hole matches. Wherein, the rack 10 is slidably matched with the guide rail 2 and detachably connected with the piston rod of the mobile cylinder 1 . The gear set 9 meshes with the rack 10 , one end of the connecting block 6 is fixedly connected with the gear set 9 , and the other end is fixedly connected with the arc slider 4 .

[0020] The gear set 9 includes a gear I 91, a gear II 92, and a gear III 93, the gear I 91 meshes with the rack 10, the gear II 92 meshes with the gear I 91, and the gear III93 meshes with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com