Ultraviolet light curing non-woven adhesive tape and preparation method thereof

A non-woven, ultraviolet light technology, applied in the direction of adhesives, non-polymer organic compound adhesives, film/sheet adhesives, etc., can solve the problems of environmental protection and bonding performance that need to be further improved. Long-lasting viscosity, not easy to be damaged between layers, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

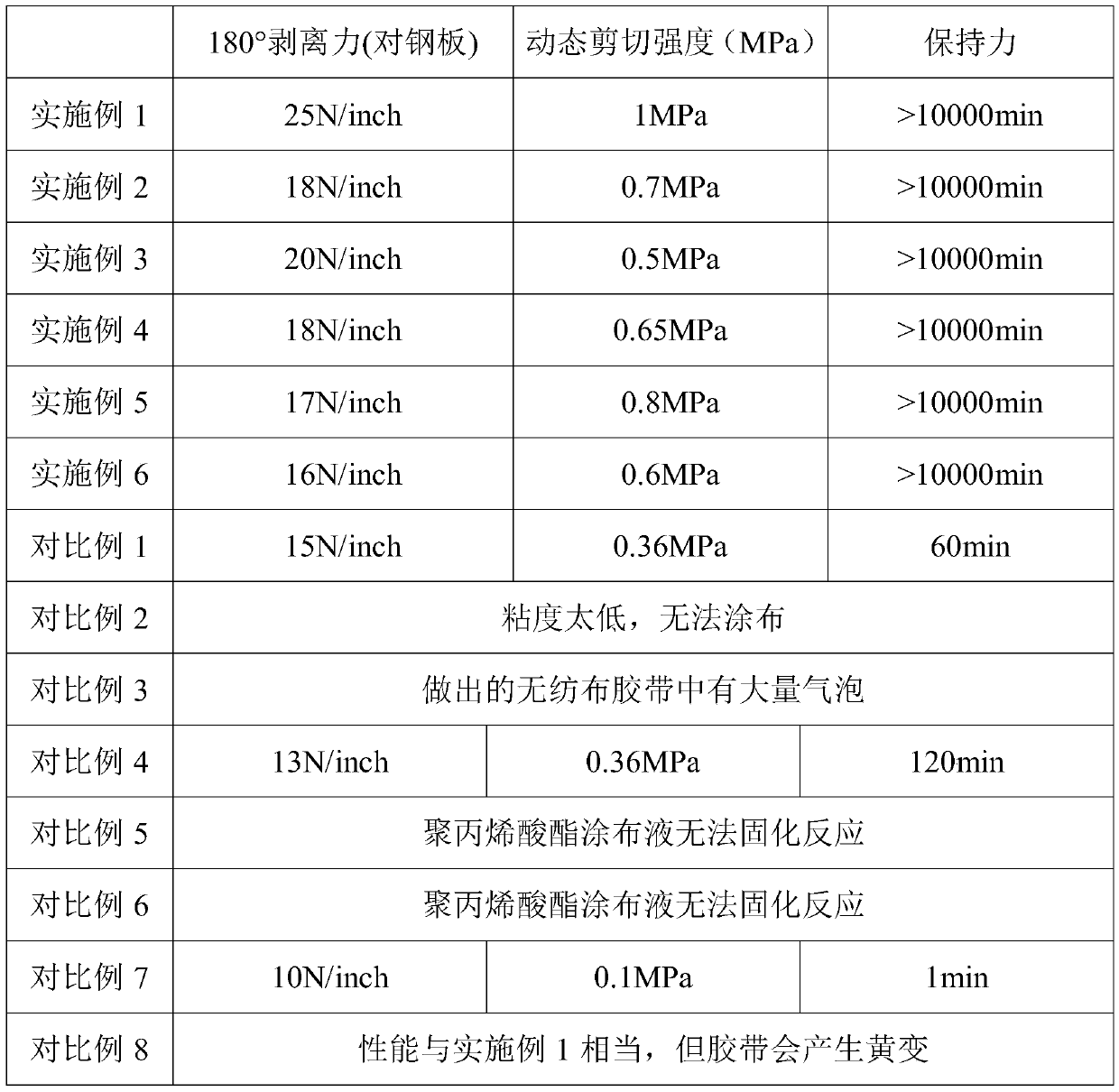

Examples

Embodiment 1

[0052] 1) By weight, 12.5 parts of acrylic acid and 87.5 parts of isooctyl acrylate are mixed and copolymerized into an oligomer with a viscosity of 5000CPS;

[0053] 2) In parts by weight, 100 parts of the above-mentioned oligomer, 0.1 part of crosslinking agent 1,6-hexanediol diacrylate, and 0.08 part of photoinitiator benzoin dimethyl ether were mixed to obtain a UV-curable polyacrylic acid Ester coating solution;

[0054] 3) Inject the above-mentioned UV-curable polyacrylate coating solution into the coating machine for coating, and the non-woven fabric weight is selected as 6g / m 2 , and cured by ultraviolet light with a wavelength of 365nm into a non-woven double-sided tape with a total thickness of 80 μm, wherein the radiation energy of ultraviolet light curing is 3000MJ.

Embodiment 2

[0056] 1) In parts by weight, 3 parts of acrylic acid, 85 parts of isooctyl acrylate and 12 parts of isobornyl acrylate are mixed and copolymerized into an oligomer with a viscosity of 4000CPS;

[0057] 2) In parts by weight, 100 parts of the above-mentioned oligomer, 0.1 part of crosslinking agent 1,6-hexanediol diacrylate, and 0.08 part of photoinitiator benzoin dimethyl ether were mixed to obtain a UV-curable polyacrylic acid Ester coating solution;

[0058] 3) Inject the above-mentioned UV-curable polyacrylate coating solution into the coating machine for coating, and the non-woven fabric weight is selected as 6g / m 2 , and cured by ultraviolet light with a wavelength of 300nm into a non-woven double-sided tape with a total thickness of 60 μm, wherein the radiation energy of ultraviolet light curing is 2000MJ.

Embodiment 3

[0060] 1) In parts by weight, 3 parts of acrylic acid, 85 parts of isooctyl acrylate, and 12 parts of isobornyl acrylate are mixed and copolymerized into an oligomer with a viscosity of 3000CPS;

[0061] 2) In parts by weight, 100 parts of the above-mentioned oligomers, 0.12 parts of crosslinking agent 1,6-hexanediol diacrylate, 0.25 parts of photoinitiator benzoin dimethyl ether, and 20 parts of hydrogenated rosin glyceride are prepared by mixing Obtain UV-curable polyacrylate coating solution;

[0062] 3) Inject the above-mentioned UV-curable polyacrylate coating solution into the coating machine for coating, and the non-woven fabric weight is selected as 6g / m 2 , and cured by ultraviolet light with a wavelength of 365nm into a non-woven double-sided tape with a total thickness of 70 μm, wherein the radiation energy of ultraviolet light curing is 5000MJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com