Temperature-equalizing plate and manufacture method thereof

A manufacturing method and technology of vapor chambers, which are applied to lighting and heating equipment, coatings, indirect heat exchangers, etc., can solve the problems of increased contact thermal resistance and damage to the mechanical strength of the chamber shell, so as to improve production efficiency, The effect of improving product competitiveness and shortening production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

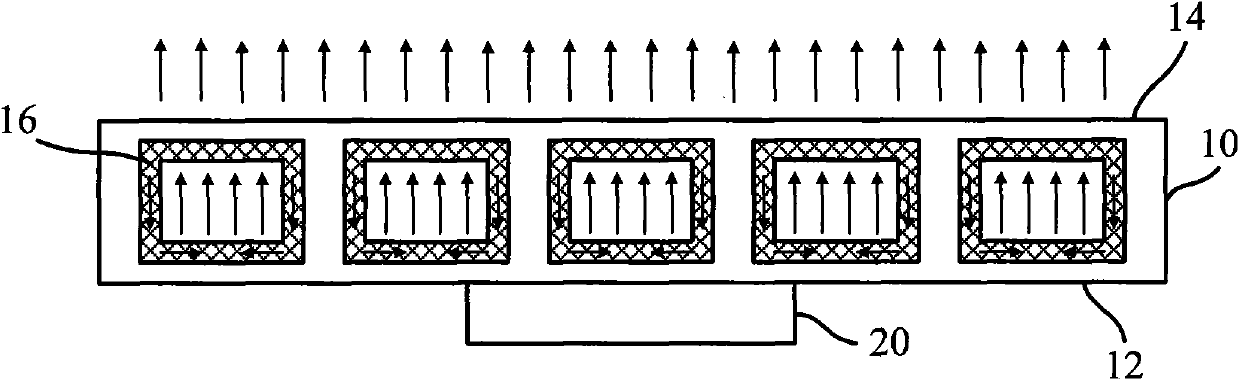

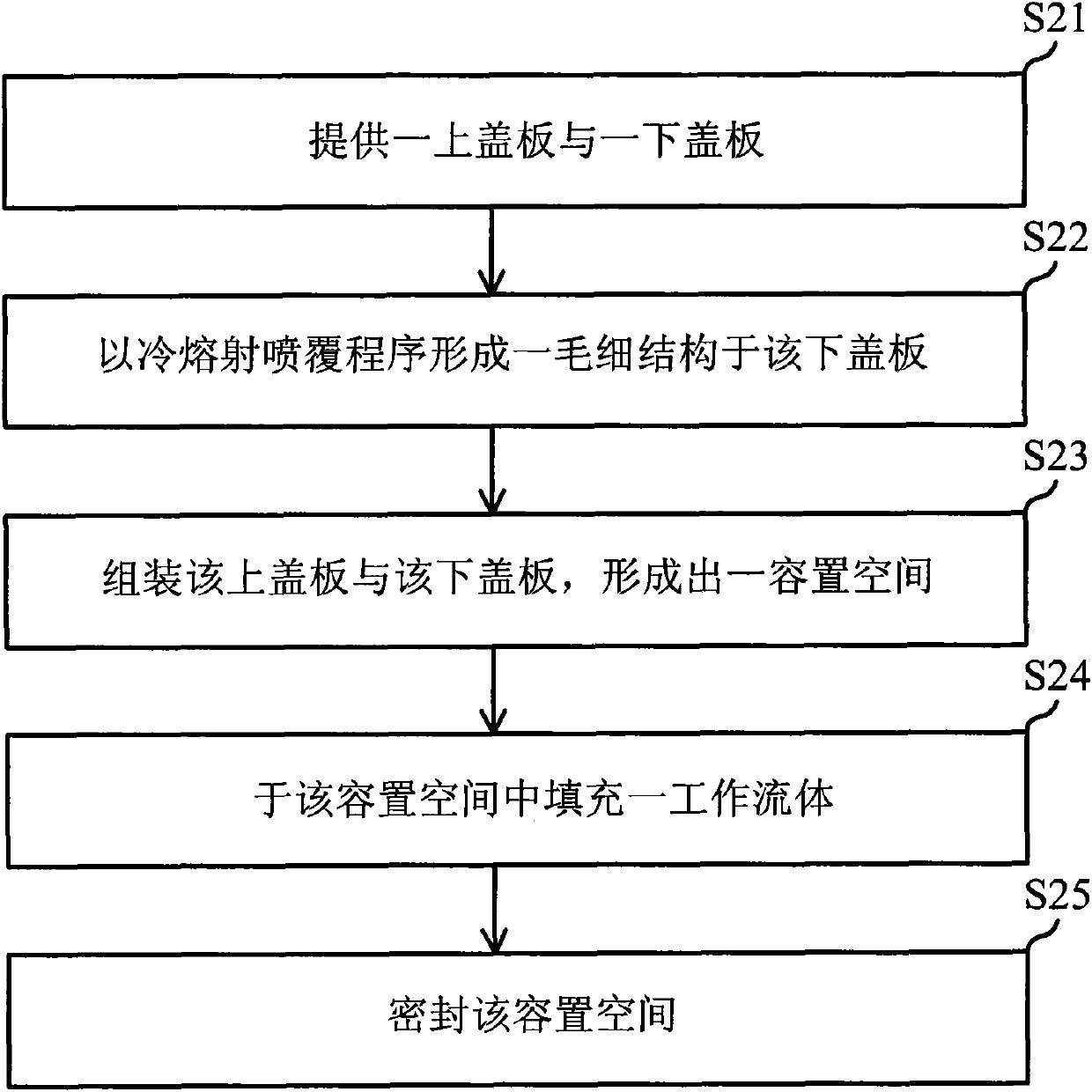

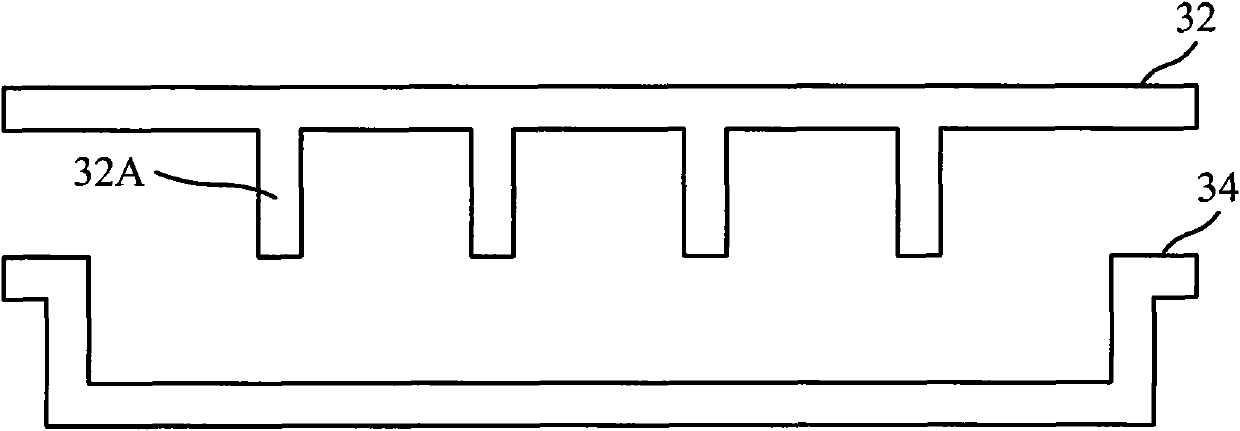

[0022] A specific embodiment according to the present invention is a method for manufacturing a temperature chamber. see figure 2 , figure 2 It is a flowchart of a manufacturing method of a temperature chamber according to a specific embodiment of the present invention. The method first executes step S21, providing an upper cover and a lower cover. For example, the manufacturer can use metal plates such as copper, aluminum, and stainless steel as materials to manufacture the upper cover plate 32 as shown in FIG. 3(A) through forging, extrusion, or casting. According to a preferred embodiment, the upper cover plate 32 is made by cold forging and stamping, but it is not limited thereto. In addition, the plurality of columnar structures below the upper cover 32 can be used as a supporting structure 32A separating the upper cover 32 and the lower cover 34 .

[0023] FIG. 3(B) shows another example of the upper and lower cover plates according to the present invention. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com