Manufacturing method of circuit board

A manufacturing method and circuit board technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as difficult handling, long process flow, damage to surface tin, etc., to shorten production time, simplify processing flow, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

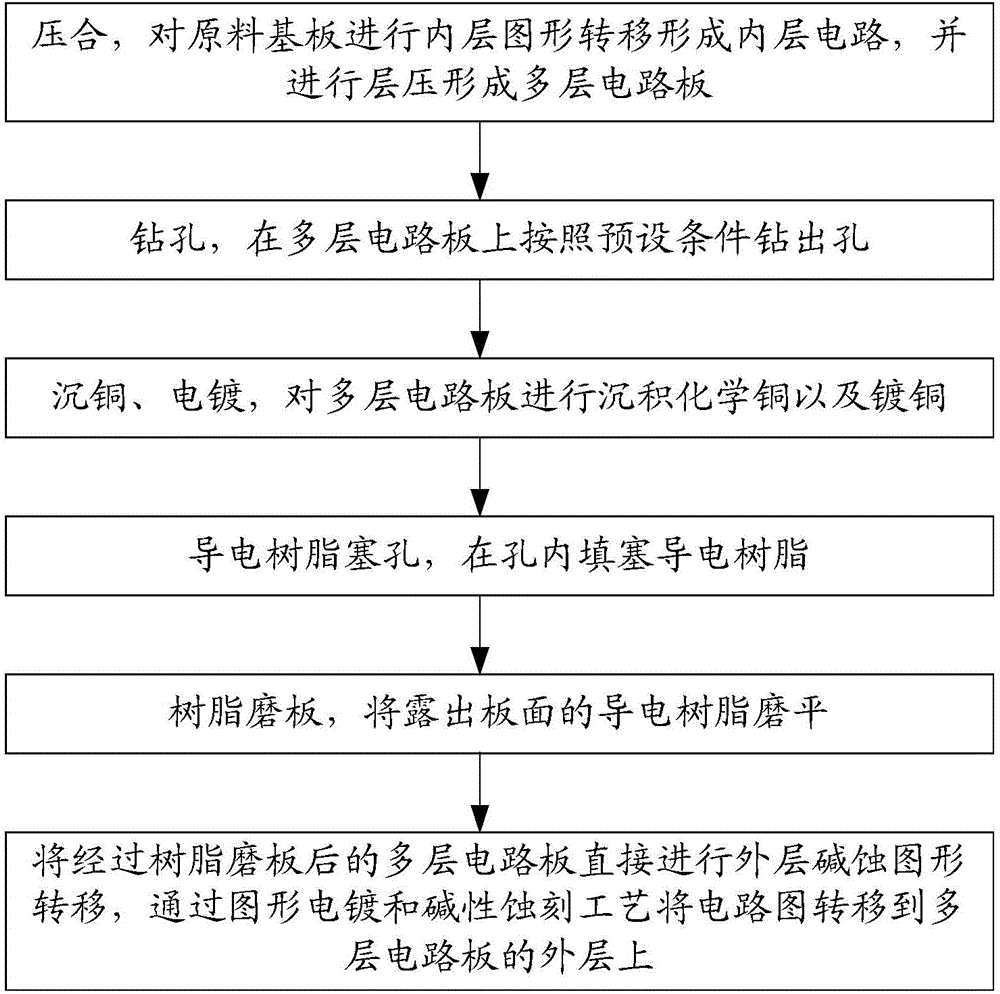

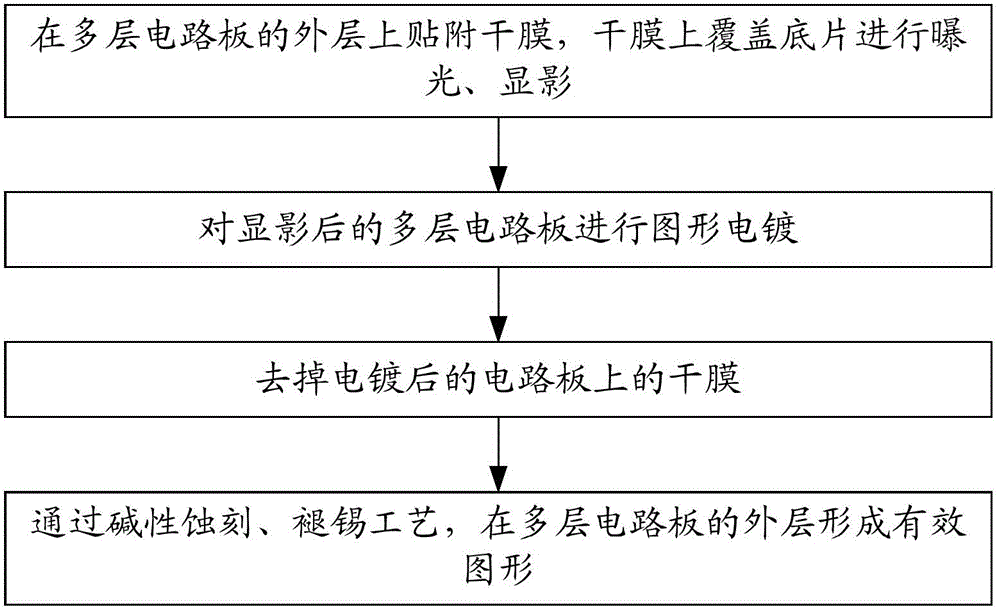

[0031] The structure and principle of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0032] In the current industry, because POFV (electroplating filling hole) cannot be obtained by alkali etching (alkaline etching, that is, electroplating first and then plugging the hole, the grinding process after the plugging hole is solidified will destroy the surface tin, and finally cannot be alkali-etched, dry The film is also worn), so the circuit board designed for POFV mainly operates in the following ways:

[0033] Lamination→drilling→immersion copper / electroplating→resin plug hole→curing→resin grinding plate→immersion copper / electroplating 2→outer layer acid etching pattern transfer;

[0034] For the above process, the circuit boards in the industry generally go through the acid etching process a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com