Automatic drainage opening cutting machine

A water cutting and automatic technology, applied in the field of water cutting, can solve the problems of prolonging the production cycle, high labor intensity, and easy fatigue of employees, and achieve the effects of reducing labor intensity, high degree of automation, and avoiding duplication of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

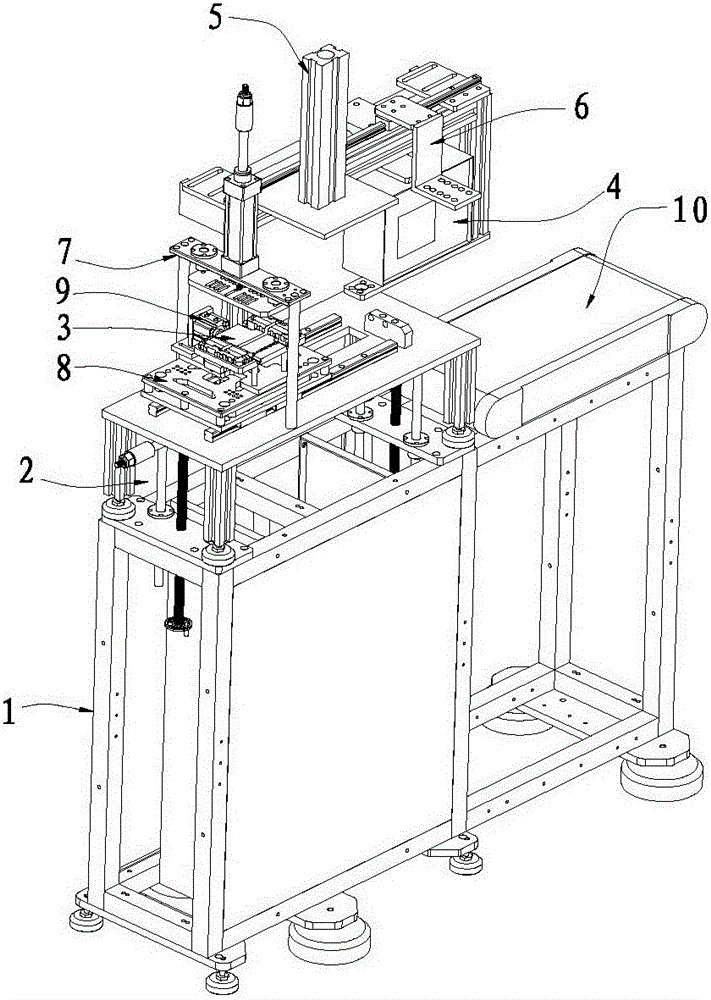

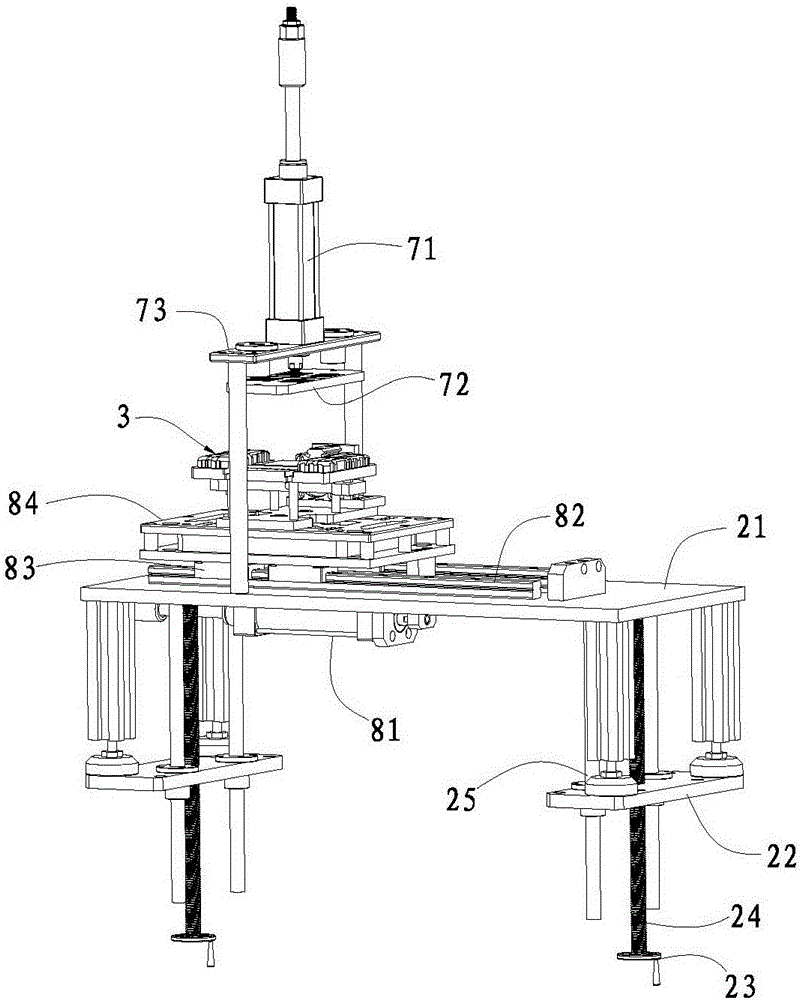

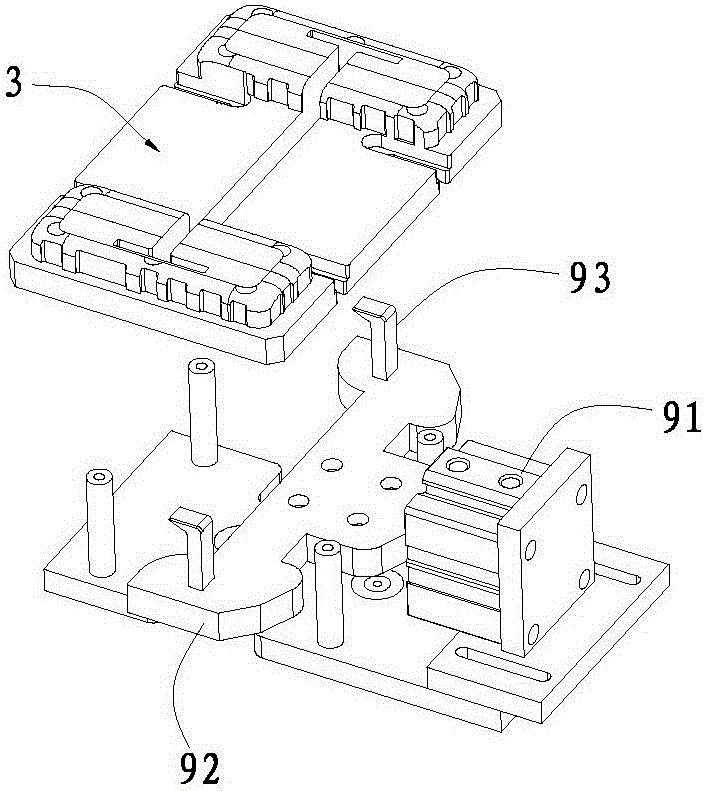

[0017] Example: see Figure 1 to Figure 4 , the present embodiment provides an automatic water cutting machine, which includes a frame 1, a horizontal lifting frame 2, a positioning fixture 3, a PLC controller 4, and a reclaiming manipulator that is respectively connected to and controlled by the PLC controller 4 5. Shifting mechanism 6, pressing mechanism 7, back pulling mechanism 8, water notch mechanism 9 and production line conveyor belt 10, the horizontal lifting frame 2 and production line conveyor belt 10 are arranged side by side on the frame 1, and the back pulling mechanism 8 is set on the horizontal lifting frame 2, the positioning jig 3 is set on the back pulling mechanism 8, the pressing mechanism 7 is set on the horizontal lifting frame 2 corresponding to the upper position of the positioning jig 3, and the water cutting mechanism 9 is arranged at the bottom of the positioning jig 3, and can perform water cutting action on the injection molded case of the mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com