Manufacturing method for silver-plated decorative picture carved in glass

A production method and technology for decorative paintings, which are applied in special decorative structures, processes for producing decorative surface effects, decorative arts, etc., can solve the needs and visual effects that cannot meet the diversity of forms and visual effects of consumer glass decorative paintings. Single and other problems, to achieve the effect of improving the value of art appreciation, prolonging the service life, and avoiding corrosion and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

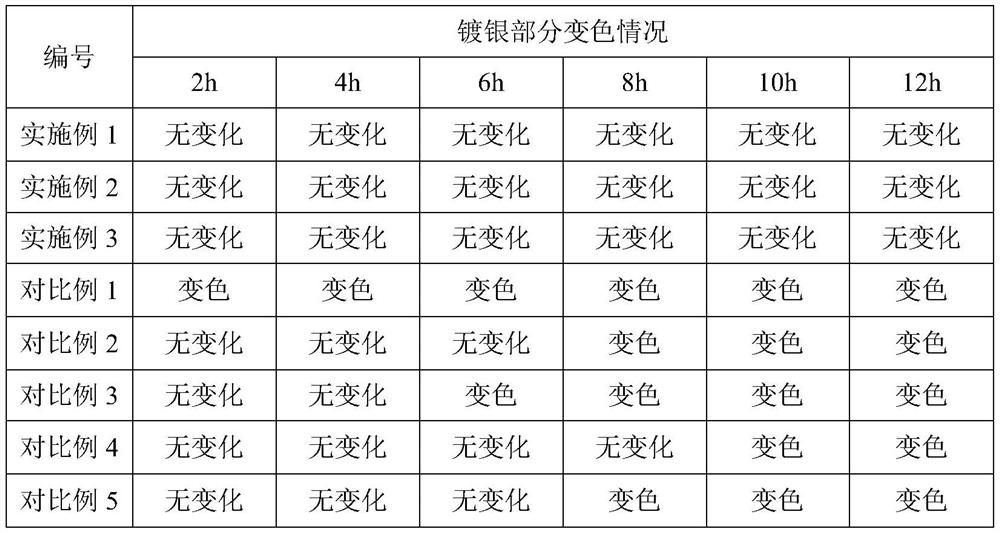

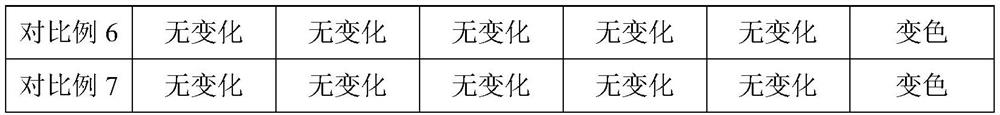

Examples

Embodiment 1

[0041] A method for making a silver-plated decorative painting carved in glass, comprising the steps of:

[0042] (1) Screen-print anti-corrosion ink (Youguang YB-950) on one side of the glass substrate, and screen-print anti-corrosion ink on the other side except for the part that needs to be etched;

[0043] (2) After the anti-corrosion ink is dried, immerse the glass substrate in the etching solution and etch for 25min and then take it out and clean it. 40% hydrofluoric acid and 60 parts water;

[0044] (3) Paste the part printed with anti-corrosion ink with anti-corrosion tape;

[0045] (4) silver spraying is carried out to the position after etching;

[0046] (5) Clean the silver-plated glass substrate and soak it in the corrosion inhibitor for 30 minutes, take it out and dry it. In parts by weight, the raw materials of the corrosion inhibitor include: 10 parts of phytic acid and 2-phenylimidazoline compound substance, 2 parts of potassium chlorate, 3 parts of polyethy...

Embodiment 2

[0055] A method for making a silver-plated decorative painting carved in glass, comprising the steps of:

[0056] (1) Screen-print anti-corrosion ink (Youguang YB-950) on one side of the glass substrate, and screen-print anti-corrosion ink on the other side except for the part that needs to be etched;

[0057] (2) After the anti-corrosion ink is dried, the glass substrate is immersed in the etching solution and etched for 20 minutes and then taken out and cleaned. In parts by weight, the components of the etching solution include 25 parts of concentrated sulfuric acid with a mass fraction of 98%. 38% hydrofluoric acid and 65 parts water;

[0058] (3) Paste the part printed with anti-corrosion ink with anti-corrosion tape;

[0059] (4) silver spraying is carried out to the position after etching;

[0060] (5) Clean the silver-plated glass substrate and soak it in the corrosion inhibitor solution for 25 minutes, take it out and dry it. In parts by weight, the raw materials of ...

Embodiment 3

[0069] A method for making a silver-plated decorative painting carved in glass, comprising the steps of:

[0070] (1) Screen-print anti-corrosion ink (Youguang YB-950) on one side of the glass substrate, and screen-print anti-corrosion ink on the other side except for the part that needs to be etched;

[0071] (2) After the anti-corrosion ink is dried, immerse the glass substrate in the etching solution and etch for 30min and then take it out and clean it. 40% hydrofluoric acid and 55 parts water;

[0072] (3) Paste the part printed with anti-corrosion ink with anti-corrosion tape;

[0073] (4) silver spraying is carried out to the position after etching;

[0074] (5) Clean the silver-plated glass substrate and soak it in the corrosion inhibitor solution for 35 minutes, take it out and dry it. In parts by weight, the raw materials of the corrosion inhibitor solution include: 15 parts of phytic acid and 2-phenylimidazoline composite Material, 3 parts of potassium chlorate, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com