Manufacturing method of cashmere painting

A production method and cashmere technology, which are applied in the directions of dyeing method, special decorative structure, embroidery machine mechanism, etc., can solve the problems of not very flat picture, pilling phenomenon of drilling down, and poor picture texture, etc. Picture pilling and drilling down, the effect of high artistic appreciation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

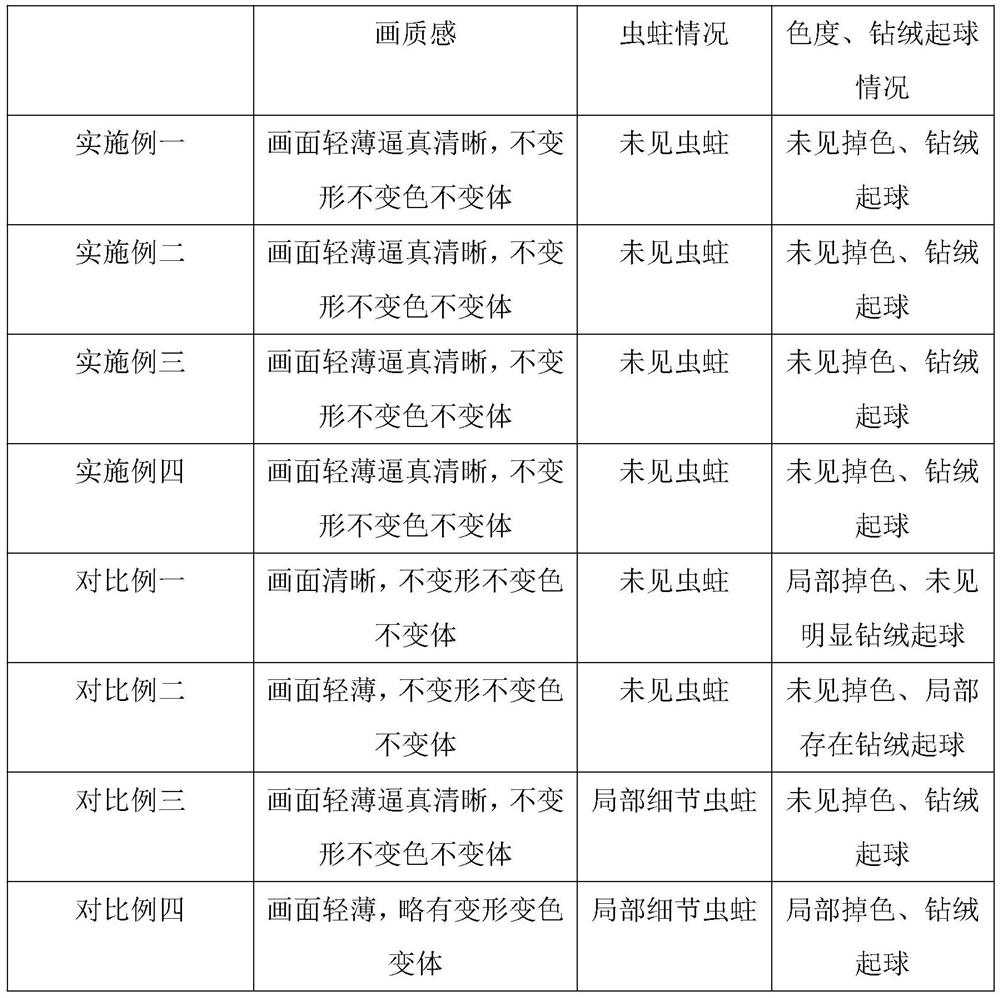

Examples

Embodiment 1

[0028] A kind of making method of cashmere painting that the present invention proposes, comprises the following steps:

[0029] S1: Select the drawing, and at the same time select the raw material as 1436 cashmere spinning;

[0030] S2: Dye the cashmere spun yarn by plant dyeing method, add diammonium phosphate in the dyeing tank after dyeing, the mass ratio of cashmere spun yarn to diammonium phosphate is 1:0.02, stir for 3 minutes, and then let stand for 40 minutes;

[0031] S3: According to the drawing, use silk thread as warp and weft to form a whole;

[0032] S4: After the overall production is completed, embroider the overall picture and details. After completion, spray triethylene glycol on the surface, and spray 100g of triethylene glycol per square meter, and then let it stand for 20 minutes;

[0033] S5: Then carry out sewing, edging, shearing, shrinking, plucking, ironing, painting repair, combined process trimming, and finally the cashmere painting is formed.

...

Embodiment 2

[0036] A kind of making method of cashmere painting that the present invention proposes, comprises the following steps:

[0037] S1: Select the drawing, and at the same time select the raw material as 1436 cashmere spinning;

[0038] S2: Dye the cashmere spun yarn by plant dyeing method, add diammonium phosphate into the dyeing tank after dyeing, the mass ratio of cashmere spun yarn to diammonium phosphate is 1:0.03, stir for 4 minutes, and then let stand for 45 minutes;

[0039] S3: According to the drawing, use silk thread as warp and weft to form a whole;

[0040] S4: After the overall production is completed, embroider the overall picture and details. After completion, spray triethylene glycol on the surface, and spray 150g of triethylene glycol per square meter, and then let it stand for 25 minutes;

[0041] S5: Then carry out sewing, edging, shearing, shrinking, plucking, ironing, painting repair, combined process trimming, and finally the cashmere painting is formed. ...

Embodiment 3

[0044] A kind of making method of cashmere painting that the present invention proposes, comprises the following steps:

[0045] S1: Select the drawing, and at the same time select the raw material as 1436 cashmere spinning;

[0046] S2: Dye the cashmere spun yarn by plant dyeing method, add diammonium phosphate into the dyeing tank after dyeing, the mass ratio of cashmere spun yarn to diammonium phosphate is 1:0.04, stir for 4 minutes, and then let stand for 55 minutes;

[0047] S3: According to the drawing, use silk thread as warp and weft to form a whole;

[0048] S4: After the overall production is completed, embroider the overall picture and details. After completion, spray triethylene glycol on the surface, and spray 250g of triethylene glycol per square meter, and then let it stand for 35 minutes;

[0049] S5: Then carry out sewing, edging, shearing, shrinking, plucking, ironing, painting repair, combined process trimming, and finally the cashmere painting is formed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com