Ceramic rail with balanced compression force and without deformation through calcination

A kind of railing and ceramic technology, applied in the direction of fences, special decorative structures, decorative arts, etc., can solve problems such as skew, uneven circular balance force in the middle of the railing, and deformation of ceramic railings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

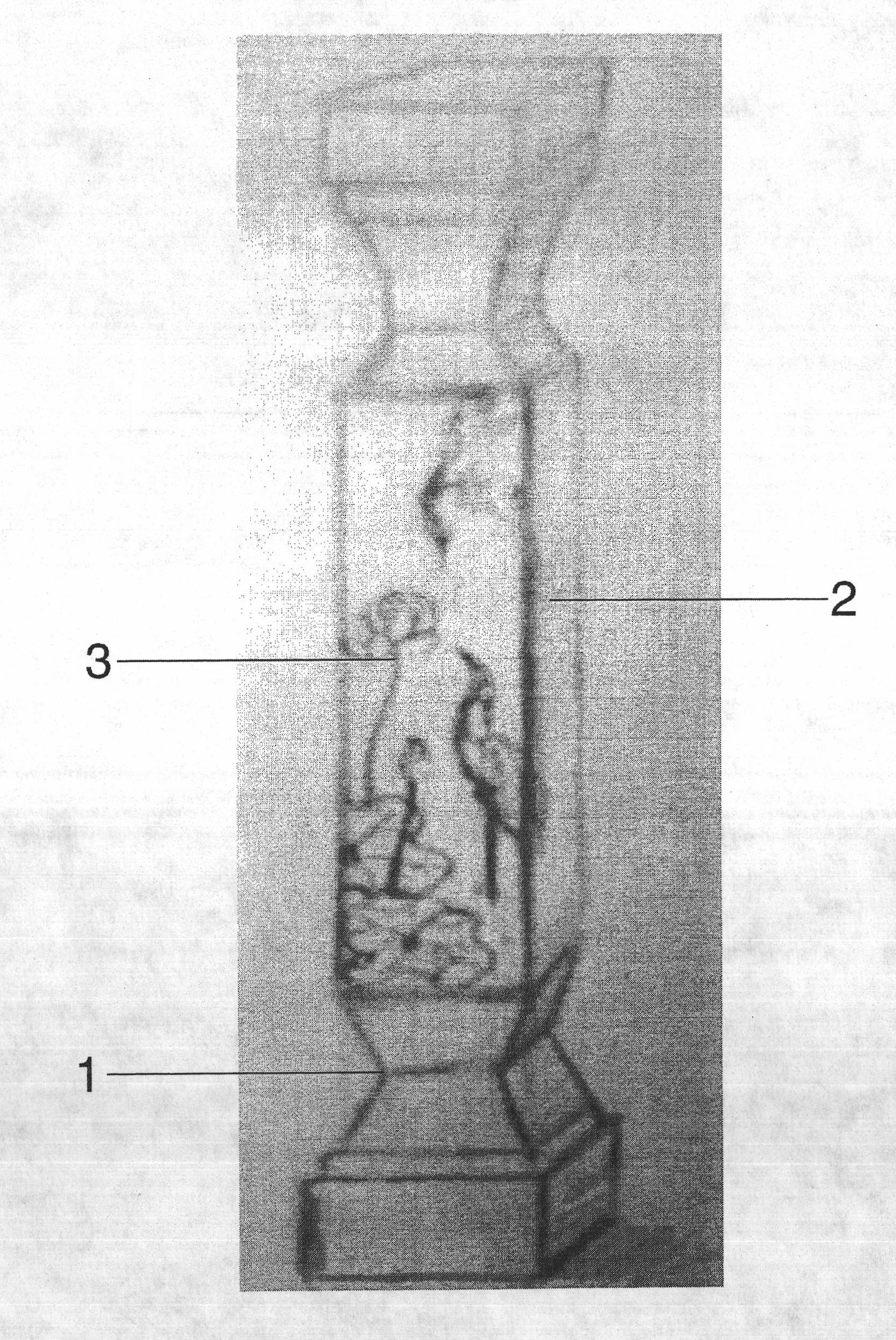

[0020] Choose ceramic raw plaster powder, finely crafted sculptures or carved into models of ceramic railings. The structure of the railing model is as follows: the fixed body at the connection part of the upper and lower ends of the railing is a rectangular square, and the parts connected to the square through a square arc are respectively provided with a square concave shape, and the front of the middle end is set as a rectangular column. The size of the rectangle at the end is 15cm*9cm, the height of the rectangle at the middle end of the railing is 25cm, and the width is 14.8cm, which is 0.2cm smaller than the rectangle. The ends are rectangular and quadrilateral. Carve or sculpt relief paintings on the rectangle in the middle of the railing, the two sides are designed as planes, and the two sides are carved with rattan clouds as an embellishment effect. The normal relief painting is about 0.3cm-0.8cm thick, and the relief painting is carved with "Jiaolong Panzhu".

[00...

Embodiment 2

[0025] Basically with embodiment 1. The difference: There are two rectangular and slightly bulging squares at the middle end connected with two arc bosses, and the upper and lower squares are square with a size of 12cm*12cm. The middle section of the railing is sculptured or engraved with "Eight Immortals Crossing the Sea" figures and landscape relief paintings.

Embodiment 3

[0027] Basically with embodiment 1. The difference: the connecting part of the rectangular square at the middle end is a slightly flat convex platform, the upper and lower ends of the circular fixed body are 14cm*10cm in size, and the middle section of the railing is sculpted or engraved with a flower-and-bird relief painting of "Blooming Wealthy Peony".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com