Construction method for chimney wall and special electric jacking flat bridge

A construction method and chimney technology, applied in the direction of formwork/formwork/work frame, building type, preparation of building components on site, etc., can solve problems such as high labor intensity of workers, and achieve simple and convenient construction operations, reduced investment, and easy construction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

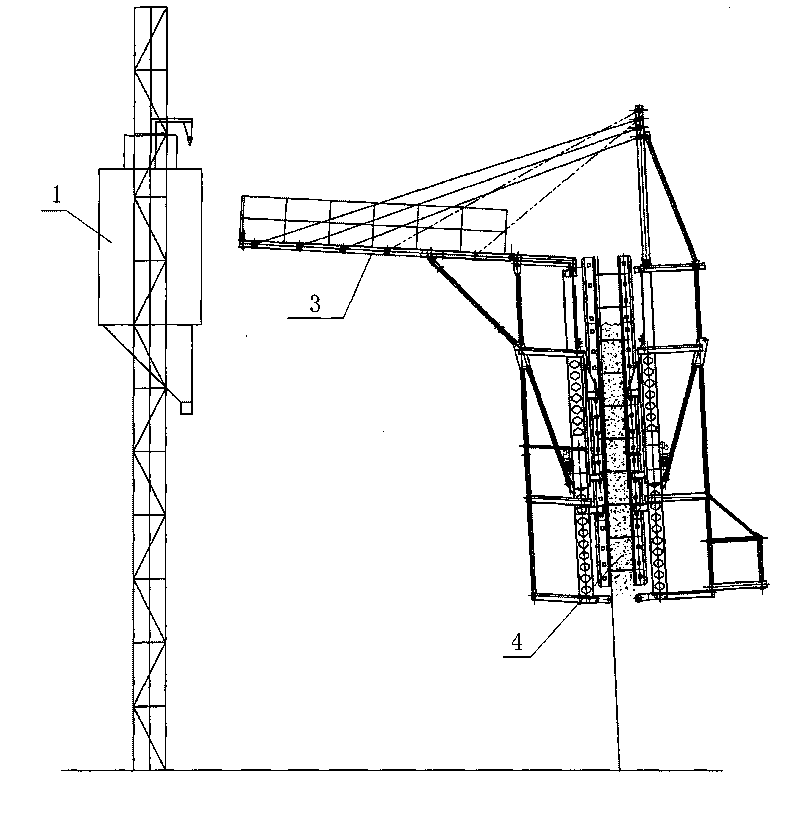

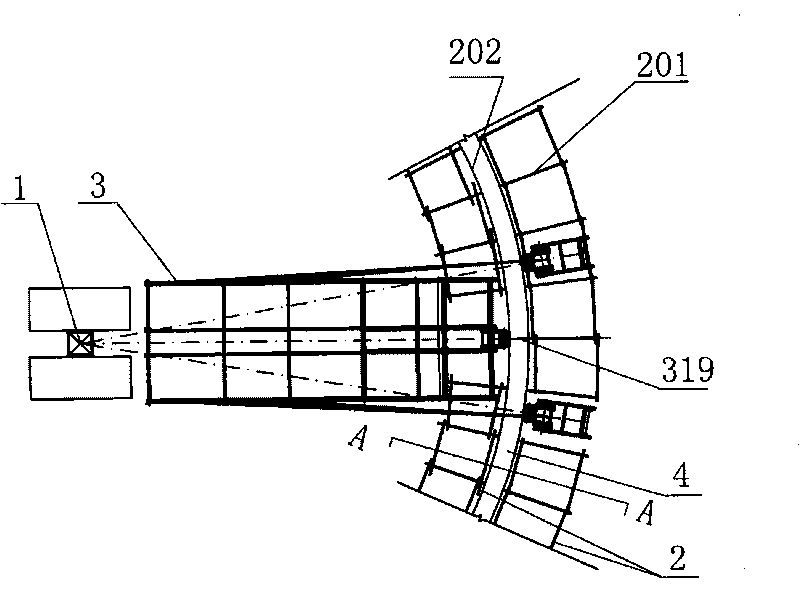

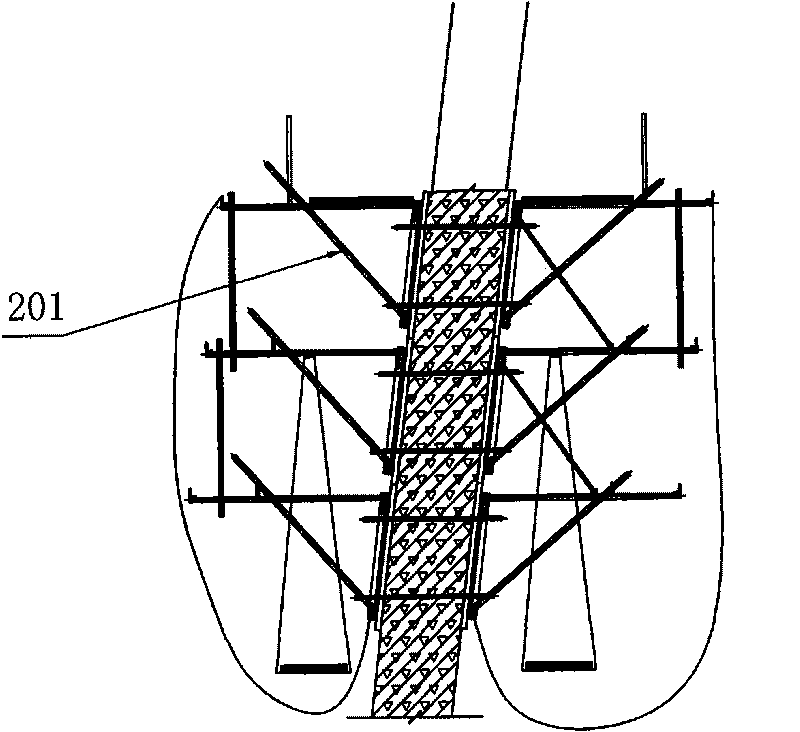

[0029]As shown in the figure, a suspended tripod turning system 2 is installed on the chimney foundation. The tripod 201 and the arc adjustment formwork 202 in the hanging tripod turning system 2 have three layers, each layer is 1500-1800mm high; Type tripod overturning system 2 builds the tube wall at the bottom of the chimney (concrete construction in the first 6 sections) and leaves the ash removal door 401; the construction elevator is installed at the center of the chimney through the ash removal door 401 as a vertical transportation device 1; On the wall 4, the electric jacking bridge 3 is erected facing the ash removal door 401. First, the three guide rails are connected to the wall opposite to the cylinder wall 4 through the high-strength bolt 319, the shear ring 6, the casing 7, the safety top cap 9, and the butterfly nut 5. The arc regulating formwork 202 is connected with each other and tightly clamps the cylinder wall, and the reinforcing plate 10 is welded on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com