Rotten root prevention construction method for shear walls, columns and other concrete vertical structures

A vertical structure and construction method technology, applied in the direction of columns, walls, pier columns, etc., can solve the problems affecting the durability and progress of the project, poor sensory quality of finished products, and low durability, so as to improve work efficiency, simple construction method, Good effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

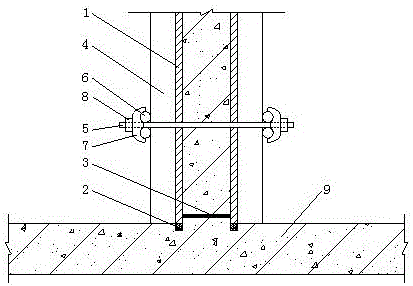

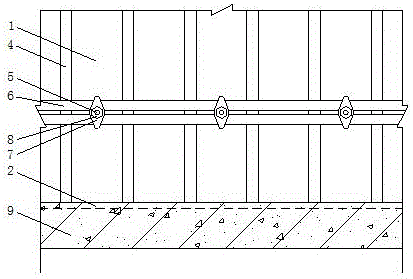

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 with figure 2 , concrete vertical structures such as shear wall, column rot prevention construction method concrete construction steps of the present invention are as follows:

[0024] Step S1: Compile the template 1 project construction plan. According to the template 1 floor plan (mold matching diagram) and relevant specifications and standards, put forward the operation process requirements, and draw the template 1 installation diagram and large sample diagram. According to the "Special Construction Plan for Formwork Engineering" compiled by the Project Department, the construction procedures are reasonably arranged to ensure project quality and construction safety, save costs and reduce project costs, and at the same time meet the requirements of civilized construction and environmental protection.

[0025] Step S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com