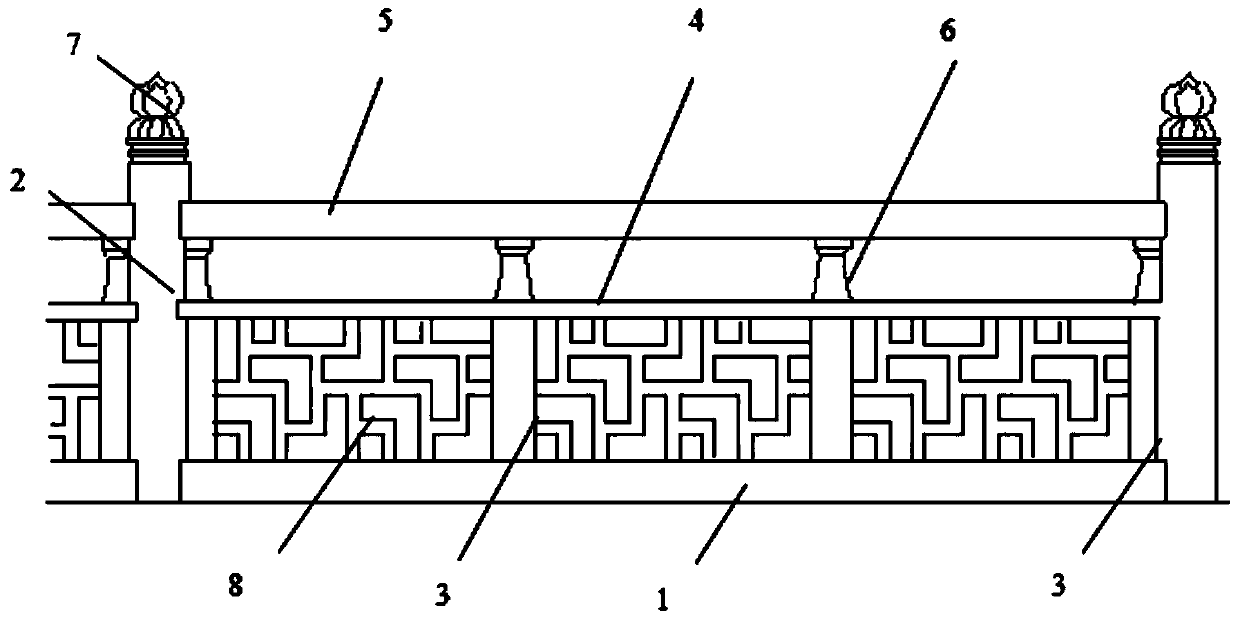

Bare concrete handrail combination overall-pouring one-step forming construction technology of pseudo-classic architecture

A technology of fair-faced concrete and antique architecture, which is applied in the direction of building types, buildings, and building structures. It can solve problems such as complex shapes of lotus stigmas and lifters, difficult construction of concrete railings, and failure to achieve the effect of fair-faced concrete. Improve the mold combination method and reinforcement method, improve the look and feel effect, and reduce the effect of repair and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The prerequisite for the realization of the one-time forming construction process of the antique building fair-faced concrete railing combination integral casting is to carry out a special systematic deepening design and customization of the mold, first determine the mold combination mode and reinforcement method, and finally realize one-time production. In the process part, some small prefabricated parts are made first, and then each component formwork of the railing and the small prefabricated parts are combined and connected effectively and accurately, so as to realize the necessary intermittent concrete from bottom to top and no construction joints for pouring, finally reaching fair-faced concrete effect.

[0036] The one-time molding construction process of the antique building fair-faced concrete railing assembly of the present invention specifically includes the following steps:

[0037] (1) First, prefabricate the molds of Shengzi 6 and Lotus Stigma 7;

[0038] (2) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com