Silo flexible slip form torsion resistance construction device

A construction device and flexible technology, applied in the field of silo flexible sliding form anti-torsion construction device, can solve a lot of problems of manpower, material resources and time, and achieve the effects of convenient operation, enhanced structural safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

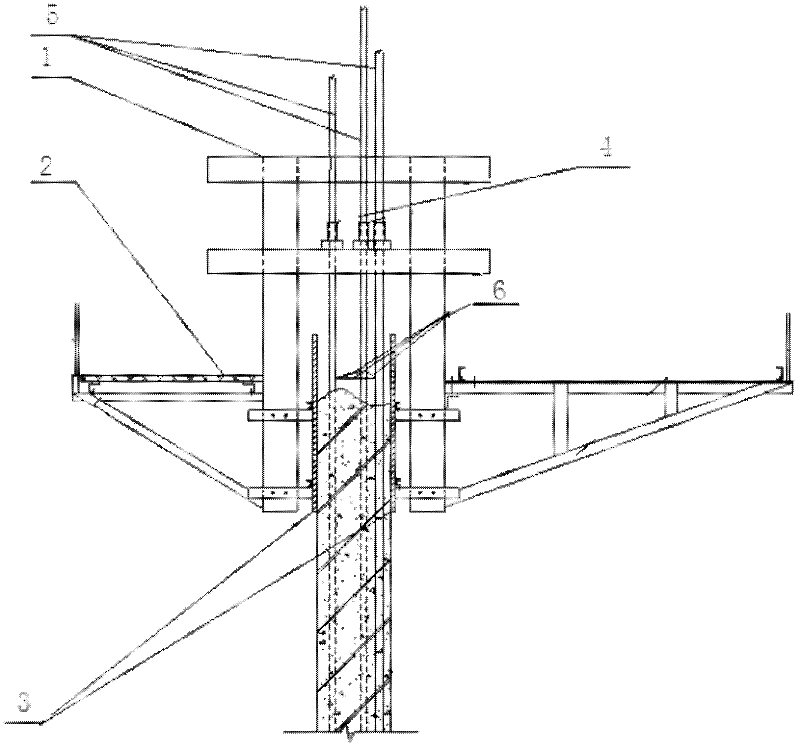

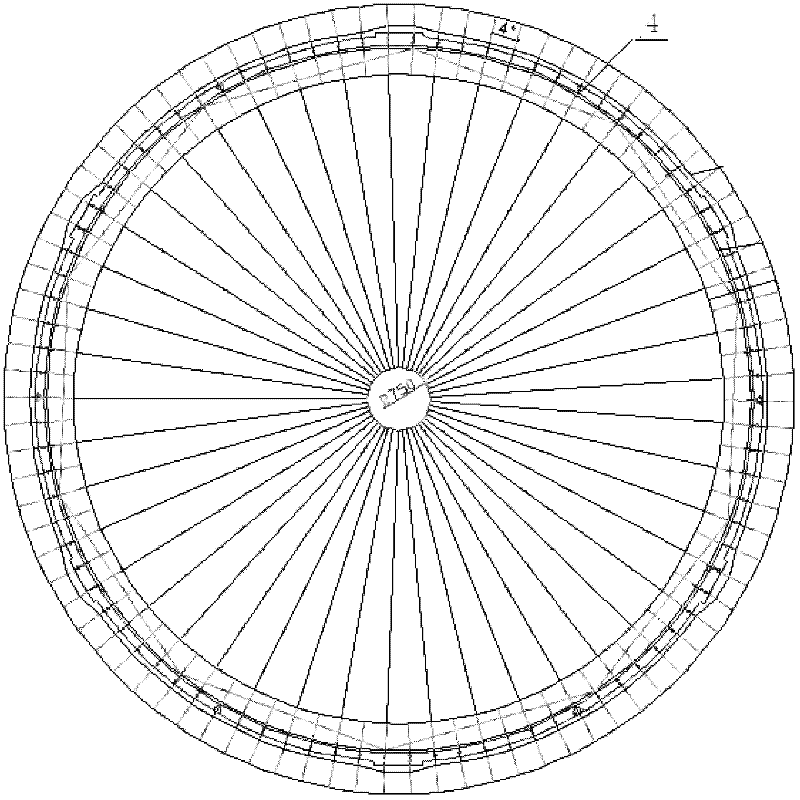

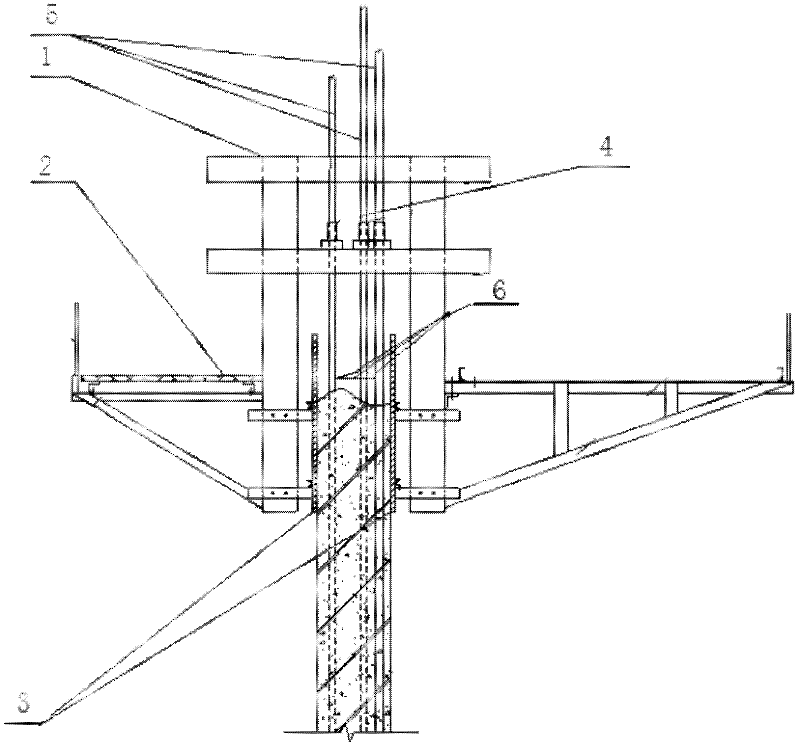

[0013] see Figure 1~2 , the present invention includes a lifting frame 1, an operating platform 2, a template 3 and a combined anti-torsion column 4 for flexible sliding form anti-torsion, and the combined anti-torsion column 4 uniformly arranged along a week of the silo wall includes a support rod 5 and a connection Rod 6, three supporting rods are arranged to form an equilateral triangle, and three connecting rods are welded between the three supporting rods to form an equilateral triangular lattice column.

[0014] The distance between the connecting rods is 350-400mm. The connecting rods are made of steel bars with a diameter of at least 20mm.

[0015] During the specific implementation, the edge line of the cylinder wall is first released at the position of the warehouse wall, and the first section of vertical steel bars and horizontal steel bars within the height range of the formwork are bound and accepted. The horizontal steel bars that exceed the height of the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com