Erecting method for reinforced concrete wall formworks

A reinforced concrete and formwork technology, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and preparation of building components on site, which can solve the threat to the lives of construction personnel on site and affect the building structure. Integrity, difficult to accurately control the reinforcement and other issues, to achieve the effect of improving construction quality, saving labor costs, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

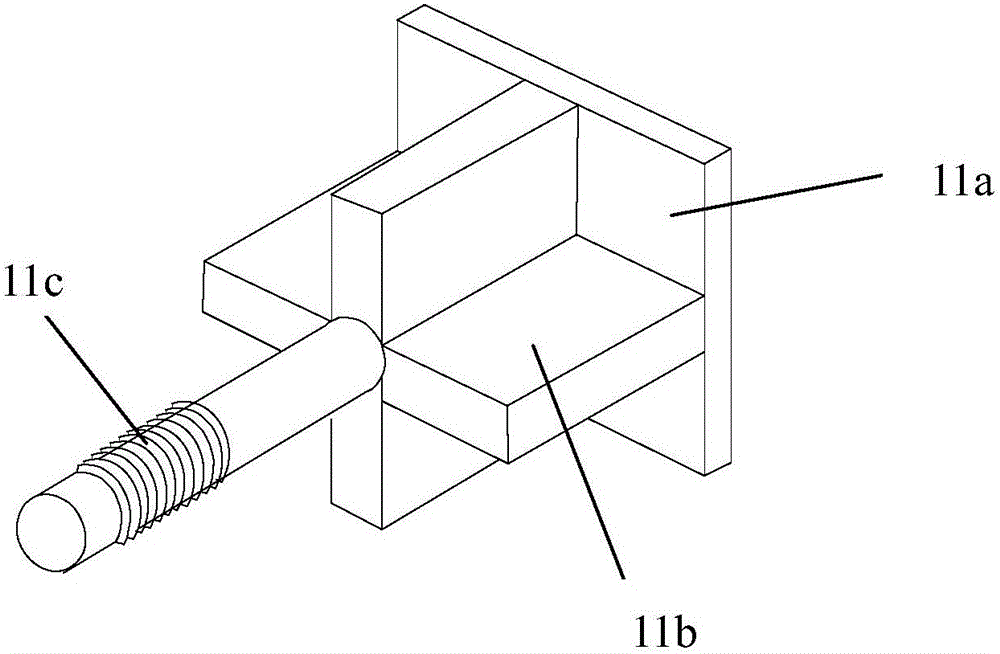

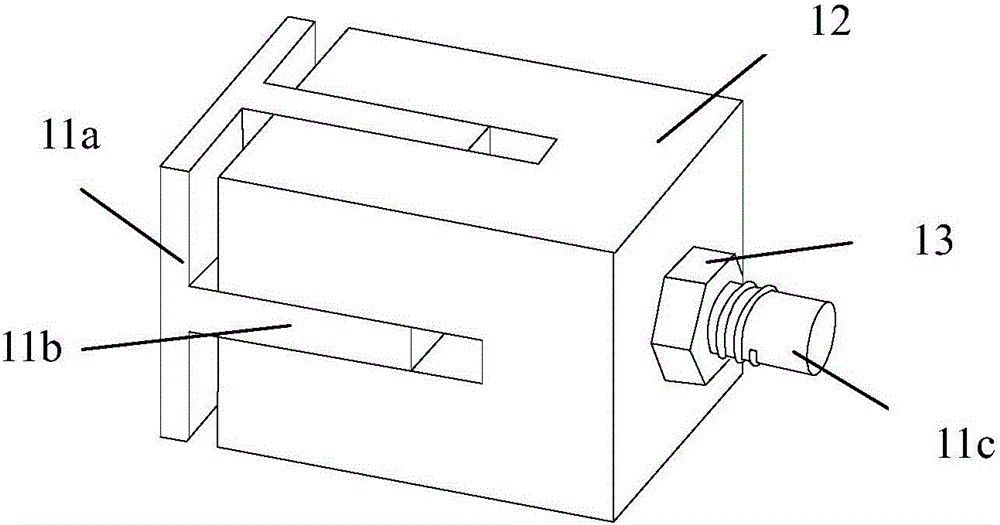

[0039] The method for erecting reinforced concrete wall formwork of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] see figure 1 and Figure 8-10 . The method of the present invention will be described below by taking the installation of 2-layer templates and installing 3 templates on each layer as an example.

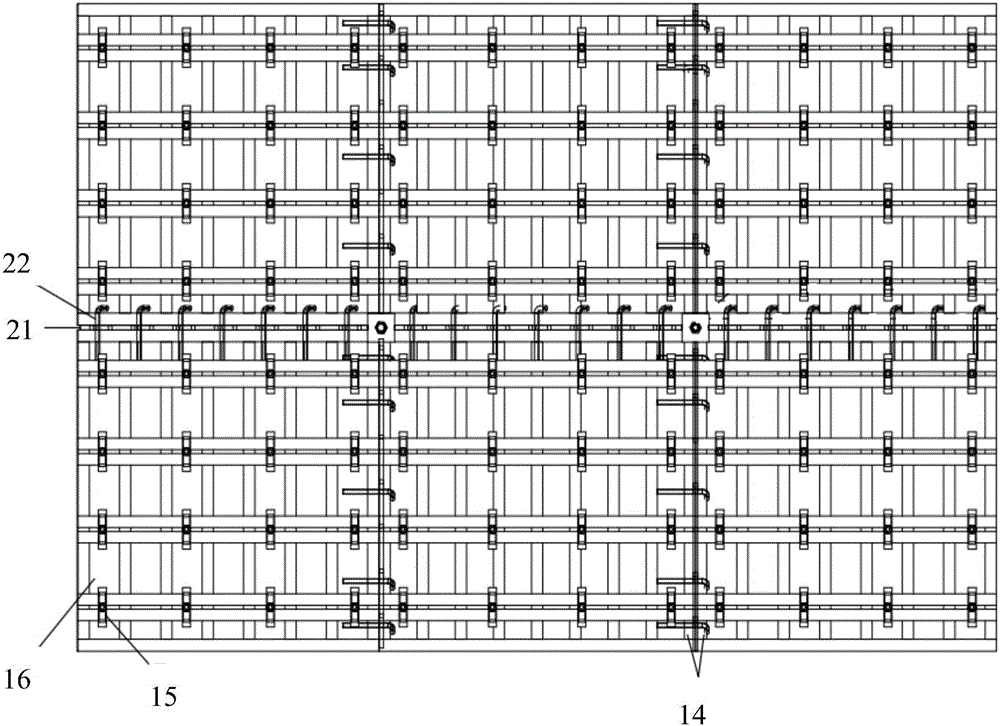

[0041] In the erecting method of reinforced concrete wall formwork of the present invention, the flat joint between two adjacent formworks is reinforced by the flat joint explosion-proof mold assembly 20 and the square wood 14, and 10 pairs of cross joint explosion-proof mold assemblies are used. The cross seams formed between the four adjacent formworks are reinforced. see Figure 9-10 Shown embodiment, this erecting method comprises the following steps:

[0042] First install the first layer of formwork: first install the 1# formwork, install the flat-joint explosion-proof mold assembly 20 at the jo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com