Onsite splicing and mounting method for extra-large and overweight box crane girders

An installation method and crane beam technology, which are applied in the field of steel structure construction, can solve the problems of inconvenient installation methods of extra-large crane beams, and achieve the effects of saving auxiliary materials and flaw detection costs, high visual quality, and light hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The 4300mm wide and thick plate project of Laiwu Iron and Steel Co., Ltd. in Shandong Province was designed by Shandong Metallurgical Design Institute and was contracted by MCC Chenggong Shanghai Fifth Metallurgy. In the history of metallurgical construction, super-long and super-heavy box crane girders are rare, realizing the idea of replacing double I-beams with box crane girders with super large column spacing in industrial plants. According to road traffic restrictions, limited by the equipment conditions of the construction site and nearby processing plants, and there is no means of transportation for a single 320-ton 54-meter-long component, the long-span box crane girder can only be manufactured by the factory, segmented, and assembled on site scheme.

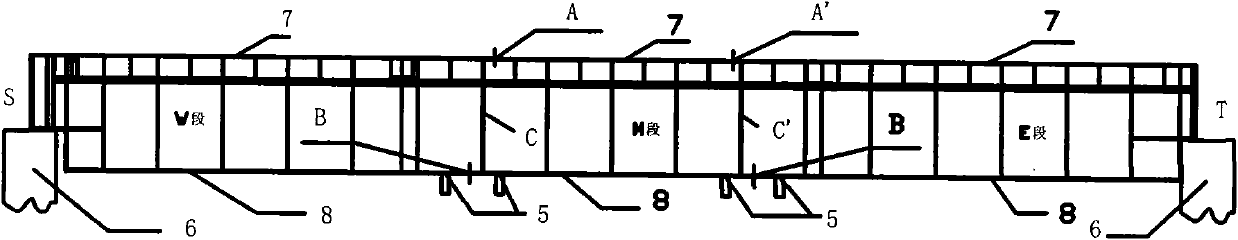

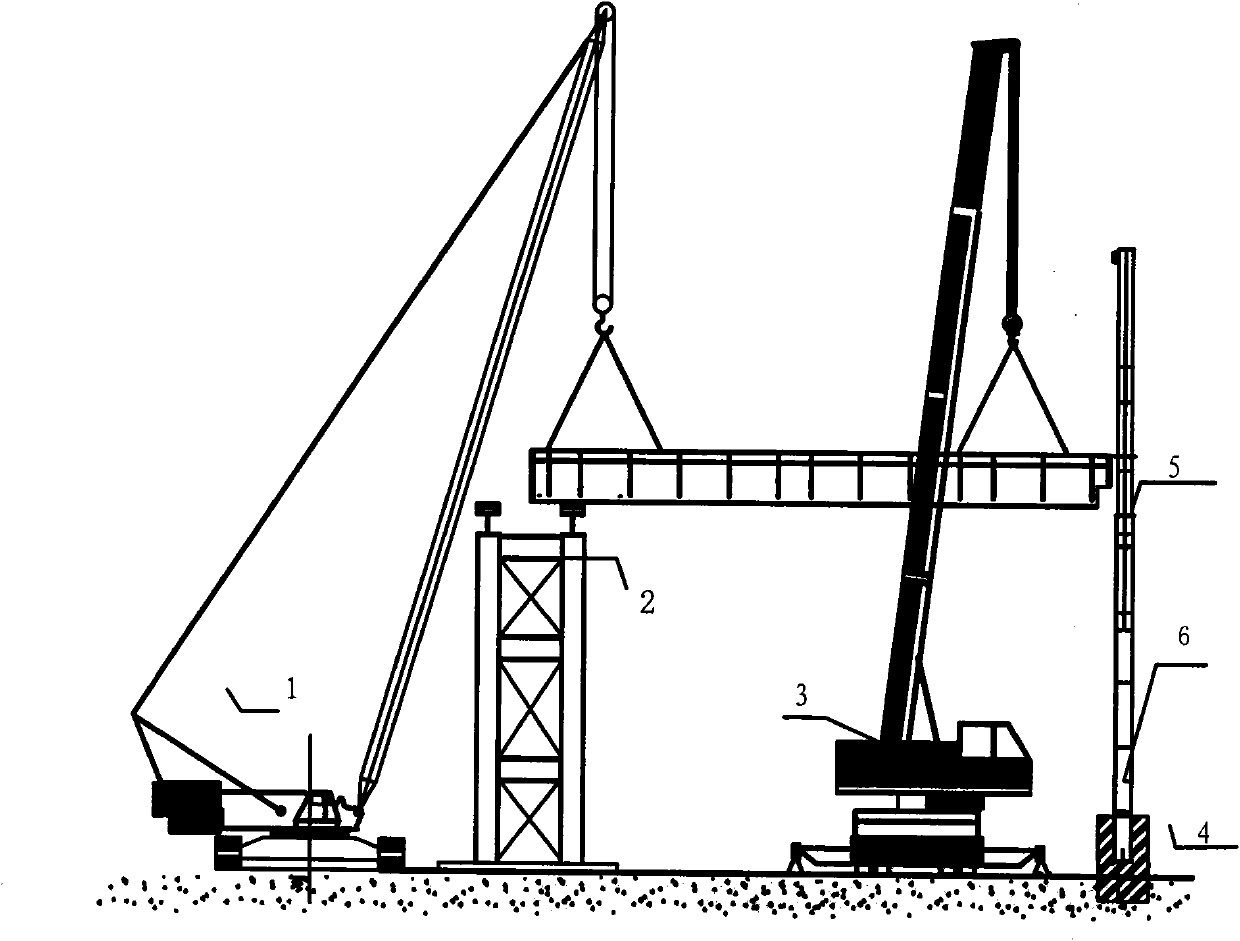

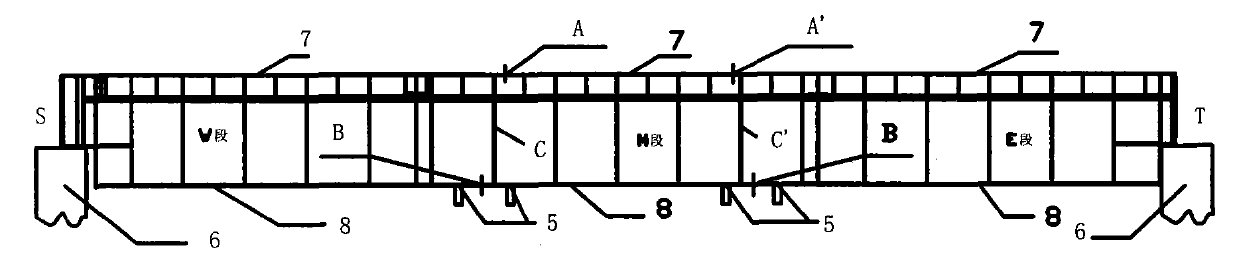

[0028] see now figure 1 and figure 2 , figure 1 It is a segmental schematic diagram of an oversized and overweight box-type crane girder according to an embodiment of the present invention, figure 2 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com