Shaping template for shear wall in deformation joint position of high-rise building

A technology for high-rise buildings and shaped templates, which is applied to the preparation of building components on site, construction, and building construction. Problems such as the surface distortion of the force wall 21 achieve the effects of improving the quality of molding and appearance, shortening the construction period, and increasing the number of turnovers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

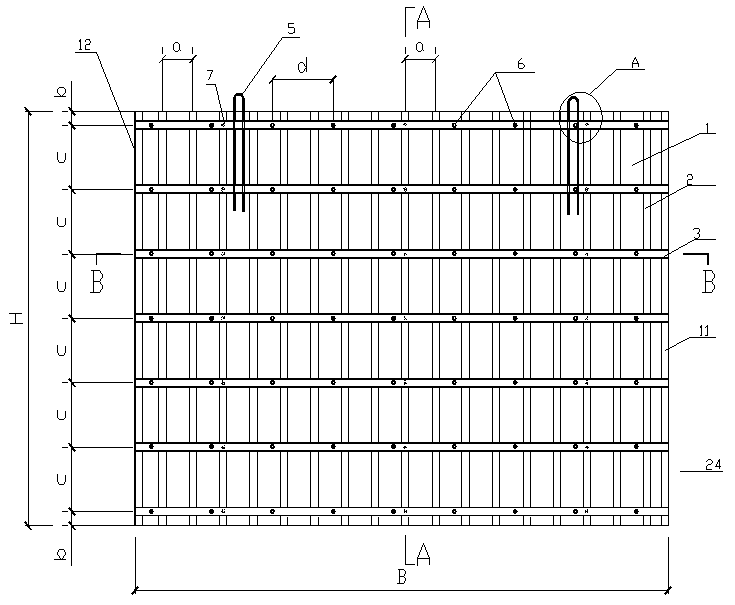

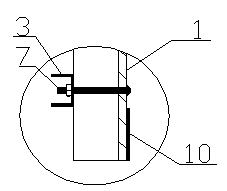

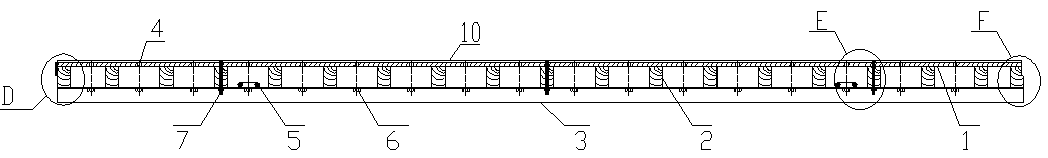

[0028] see figure 1 and figure 2 , the stereotyped formwork 24 that is used for the high-rise building deformation joint position shear wall comprises rectangular bamboo plywood 1, and the periphery of one side of bamboo plywood 1 is fixedly installed with square wood bars respectively, forms a square frame, and the bamboo plywood 1 in the square frame Upright square wooden secondary flute 2 is evenly distributed on the side, and square wooden secondary flute 2 is perpendicular to the long side of bamboo plywood 1; Vertical to the square wooden secondary flute 2, and parallel to the long side of the bamboo plywood 1; three short bolts 7 are arranged on the channel steel main flute 3, and the three short bolts 7 pass through the corresponding square wooden secondary flute 2 to connect the bamboo glue plate 1, see Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 9 There are through holes evenly distributed on the web in the notch of channel steel main flute 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com