A terrazzo brick forming machine

A molding machine and stone brick technology, applied in the field of mechanical equipment, can solve problems such as small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

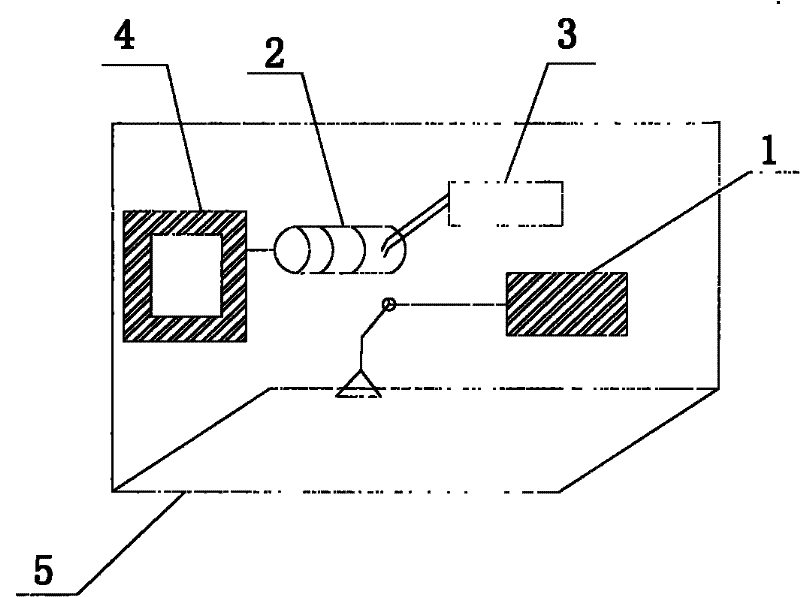

[0017] see figure 1 , a terrazzo brick molding machine, including a raw material hoist 1, a forced mixer 2, a quantitative feeder 3 and a molding host 4 located on a base 5, the raw material hoist 1 mixes cement, crushed stone, terrazzo particles and cement color paste, etc. The raw materials are lifted into the forced mixer 2, and the auxiliary raw materials for preparing terrazzo bricks are added through the quantitative feeder 3, and finally the terrazzo bricks with a size of 600*600mm are produced through the forming mold in the forming host 4.

[0018] The present invention adopts a 630mm oil cylinder to match the above-mentioned forming mold, so that the pressure of the terrazzo brick forming machine reaches 600 tons, and the produced terrazzo bricks have high strength, high density, low breakage rate and are durable.

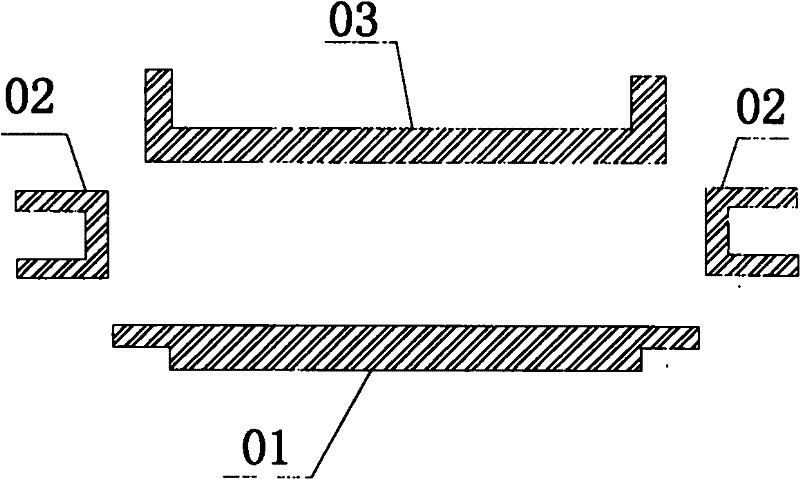

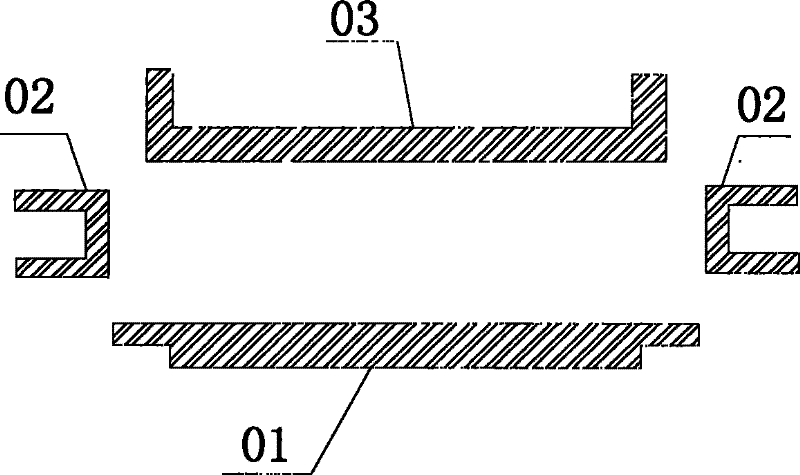

[0019] see figure 2 , the molding die that the present invention adopts is made up of assembly bottom mold 01, two left and right symmetrical side mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com