Machining method for artificial waterstone slabstone

A technology of artificial slate and terrazzo, which is applied in the field of building decoration materials, can solve problems such as stone falling off, and achieve the effects of reducing water consumption and energy consumption, clear color boundaries, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

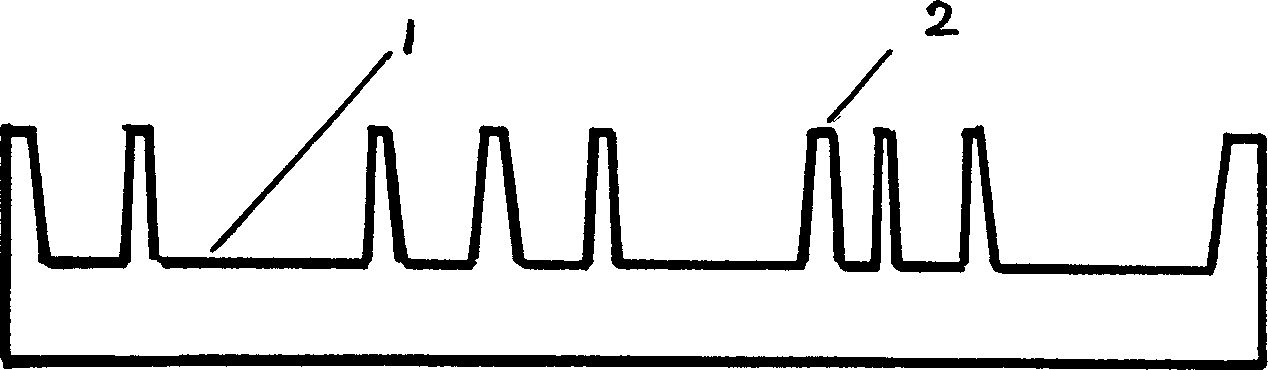

[0009] (1) Assemble a mold with a stone-like shape, the concave surface of the pattern should be on the inner side of the mold, or a lining mold with a pattern can be added to the standard mold.

[0010] (2) Apply mold release agent inside the mold.

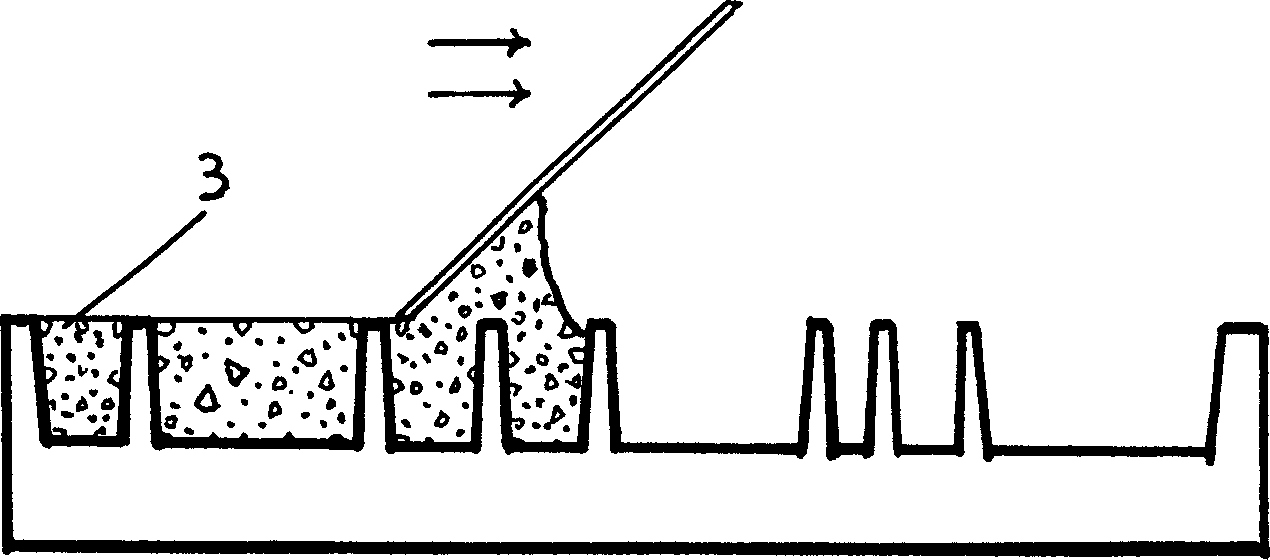

[0011] (3) Fill the colored cement mortar into the inner groove of the mold with a rubber scraper, or fill in cement mortar of various colors.

[0012] (4) Pouring concrete into the mould, smoothing and curing after polishing.

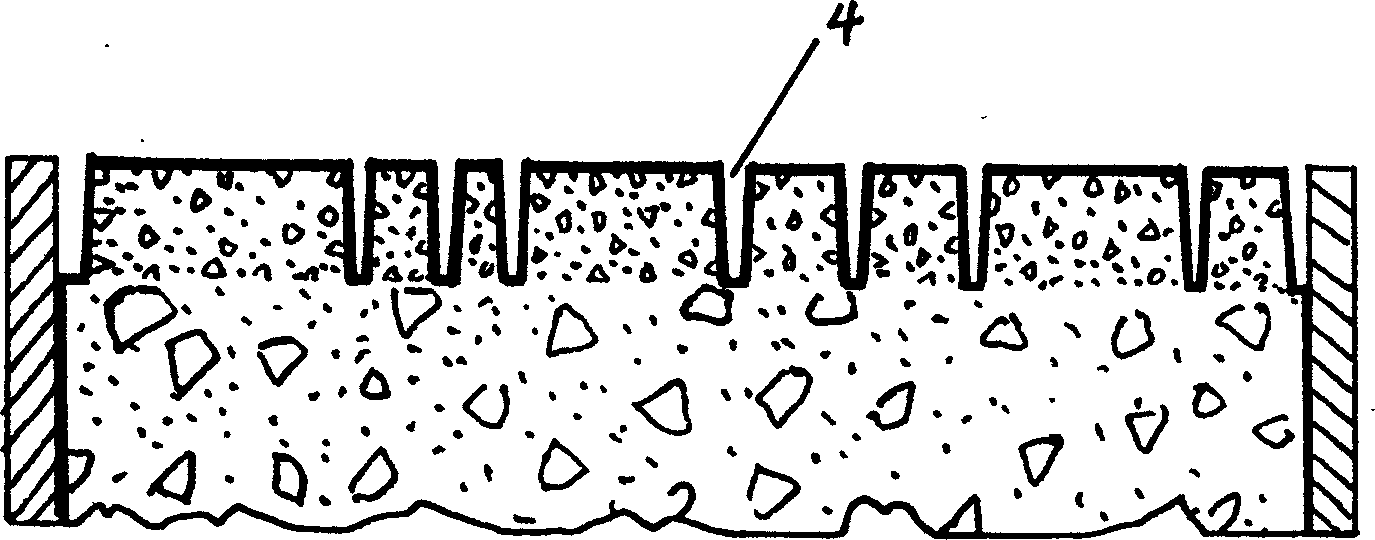

[0013] (5) After demolding, grind the surface of the workpiece with a fine whetstone, and then rinse it off.

[0014] (6) Put cement mortar of other colors into the surface groove of the workpiece, and pay attention to make the cement mortar put in higher than the stone surface of the workpiece.

[0015] (7) Grind lightly after initial setting, and polish after curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com