Steel fiber reinforced concrete manhole cover and producing method thereof

A steel fiber reinforced concrete and inspection well technology, which is used in the manufacture of tools, artificial islands, underwater structures, etc., can solve the problems of insufficient concrete adhesion, cracking, and the surface cannot be ground, so as to improve the adhesion. , to prevent safety accidents, the effect of low recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

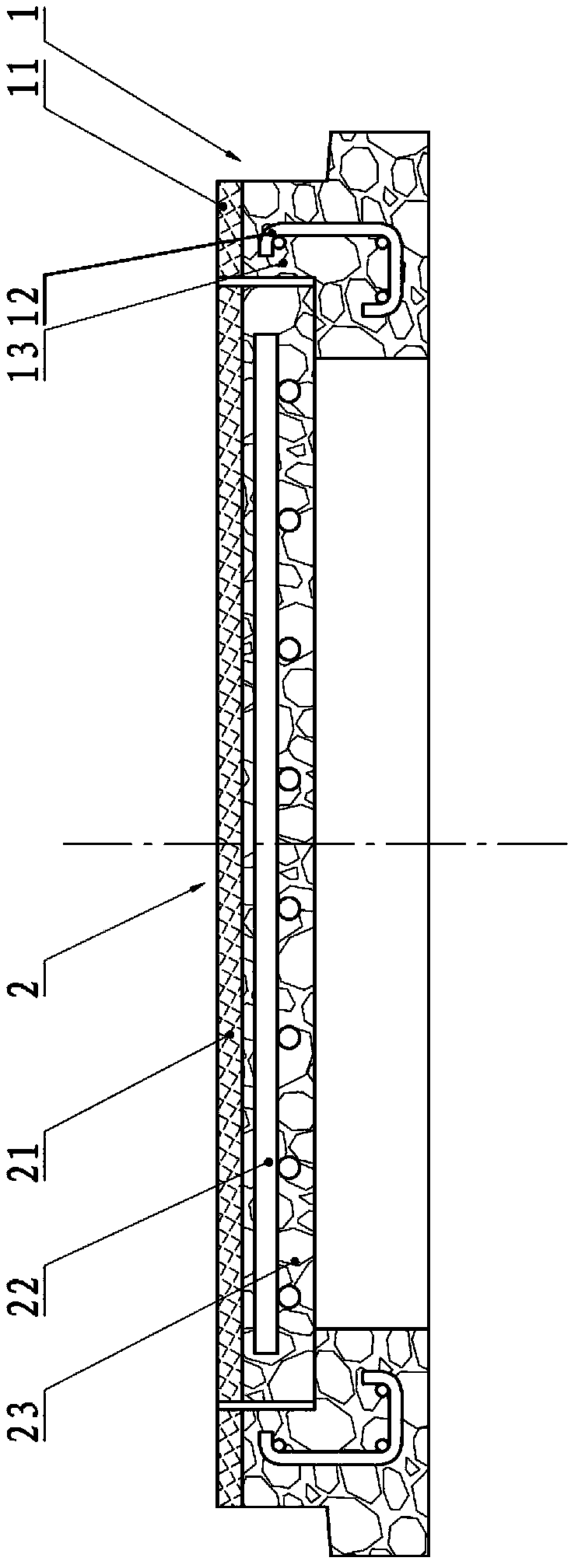

[0011] Embodiment one, a rainwater well well seat and well cover, are E600 grade, wellhead diameter 600mm, and its structure is as follows figure 1 shown. The well cover 2 has a terrazzo surface layer 21 and a steel fiber concrete bottom layer 23, the surface layer is 15mm thick, the total thickness is 130mm, and the reinforcement diameter is 14mm. The well base 1 also has a terrazzo surface layer 11 and a steel fiber concrete bottom layer 13. The surface layer is 15mm thick and the total height is 130mm. Reinforcement: the main reinforcement has a diameter of 10mm and there are three rings. Two, the next one on the inner side, the auxiliary reinforcement diameter 8mm is hooped on the three rings by the radial line to form a steel bar skeleton 12.

[0012] Manufacturing steps:

[0013] 1. Consolidated steel skeleton, spare.

[0014] 2. Prepare the mold and set aside.

[0015] 3. Preparation of terrazzo slurry for the surface layer: 50 parts by mass of 42.5 grade ordinary P...

Embodiment 2

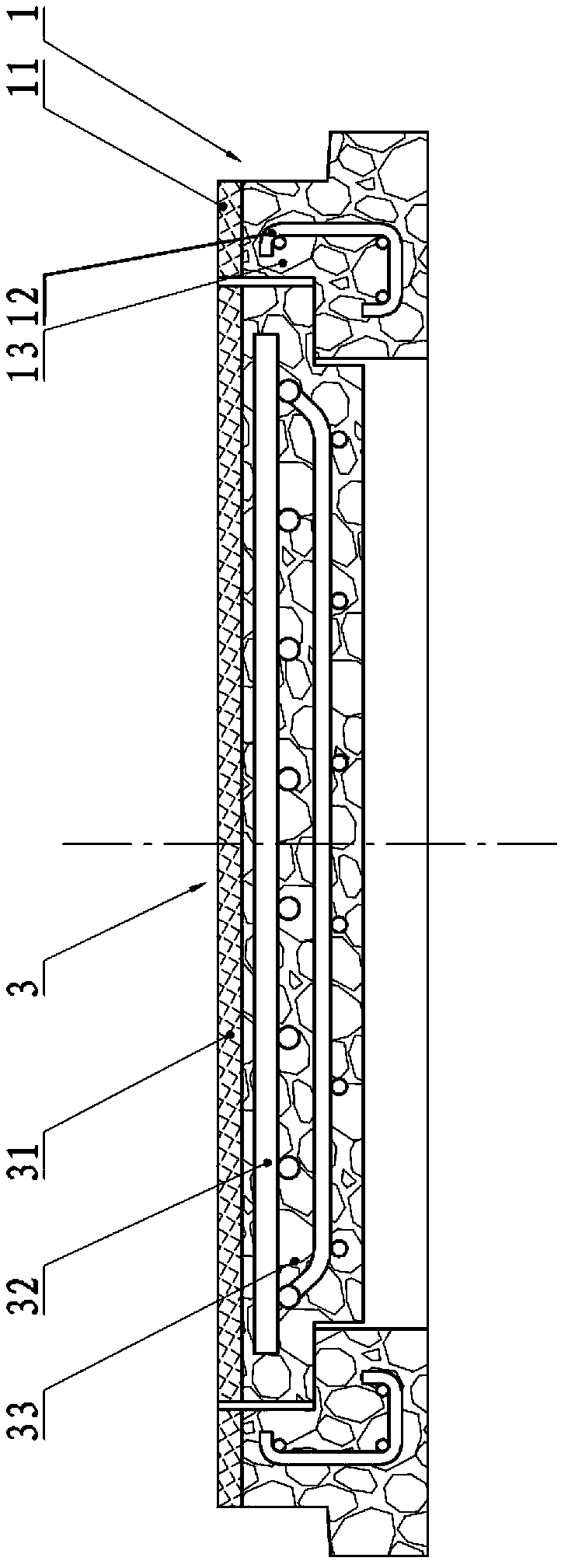

[0024] Manufacturing steps are as above example, wherein the structure of manhole cover 3 is as figure 2 As shown, a step protrudes downward from the bottom surface of the bottom layer 33, the diameter of the step is 595mm, and the height is 30mm. The 32 reinforcements of the reinforcement frame are added one more layer under the reinforcement of the previous example, which is 10mm in diameter, and fixed vertically and horizontally at intervals of 100mm. The ends of the lower steel bars are bent upwards and welded to the upper steel bars. When pouring, the mold is just being placed and the bottom layer is vibrated firmly first, and then the surface layer 31 is vibrated firmly and smoothed. The structure of the surface course 11, the bottom layer 13 and the reinforcement frame 12 of the well block 1 is as above example.

[0025] In addition, the composition and dosage of the surface layer are: 49 parts by mass of general-purpose Portland cement with a strength grade of 42.5,...

Embodiment 3

[0027] As in the above example, the components and dosage of the surface layer are: 50 parts by mass of general-purpose Portland cement with a strength grade of 42.5, 130 parts by mass of quartz sand with a particle size range of 4-6 mm, 0.05 parts by mass of hydroxypropyl cellulose, 0.11 parts by mass of construction rubber powder and 0.04 parts by mass of Chuhong pigment; the components and dosage of the bottom layer are: 99 parts by mass of general-purpose Portland cement of grade 42.5, 60 parts by mass of sand, and 330 parts by mass of gravel flakes with a particle size range of 15-20mm parts by mass, 0.11 parts by mass of hydroxypropyl cellulose, 0.24 parts by mass of construction rubber powder, and 20 parts by mass of steel fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com