A layout method for energy saving of factory lighting

A technology for factory lighting and factory areas, applied in lighting devices, light sources, electrical components, etc., can solve problems such as difficult compatibility, lamps and appliances scrapped, and low recycling value, so as to reduce material and labor costs, improve efficiency, and realize The effect of overall voltage reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

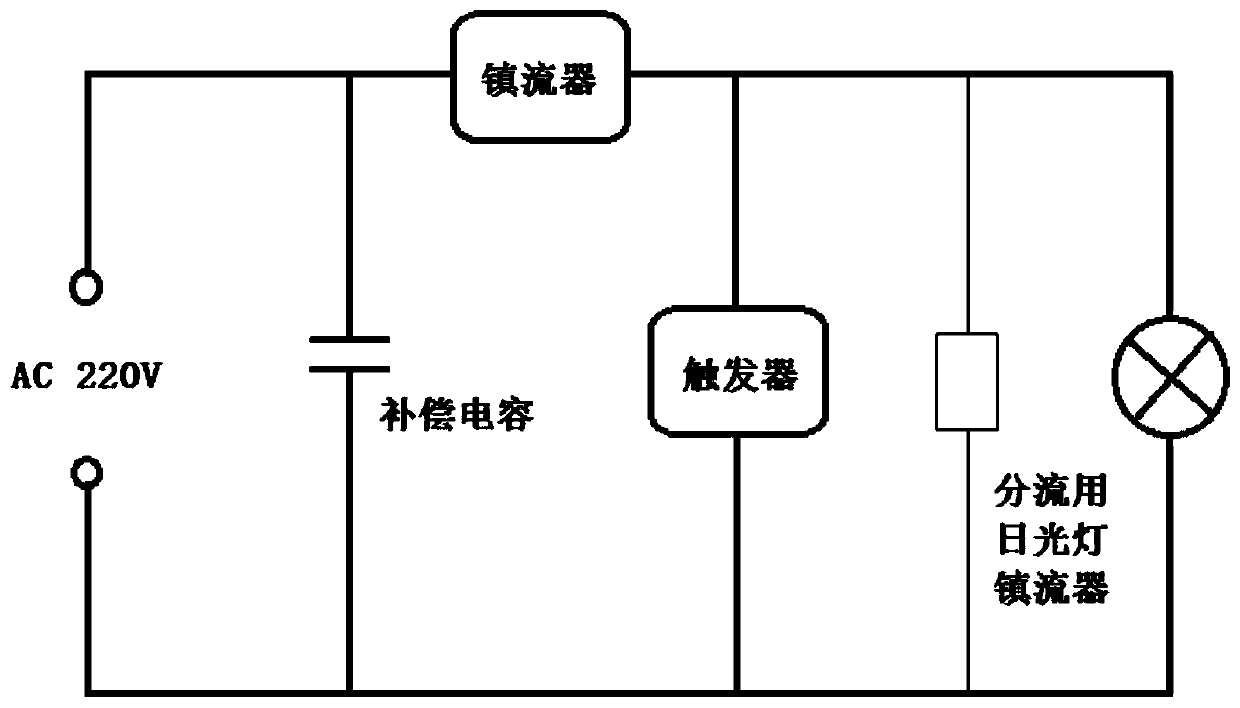

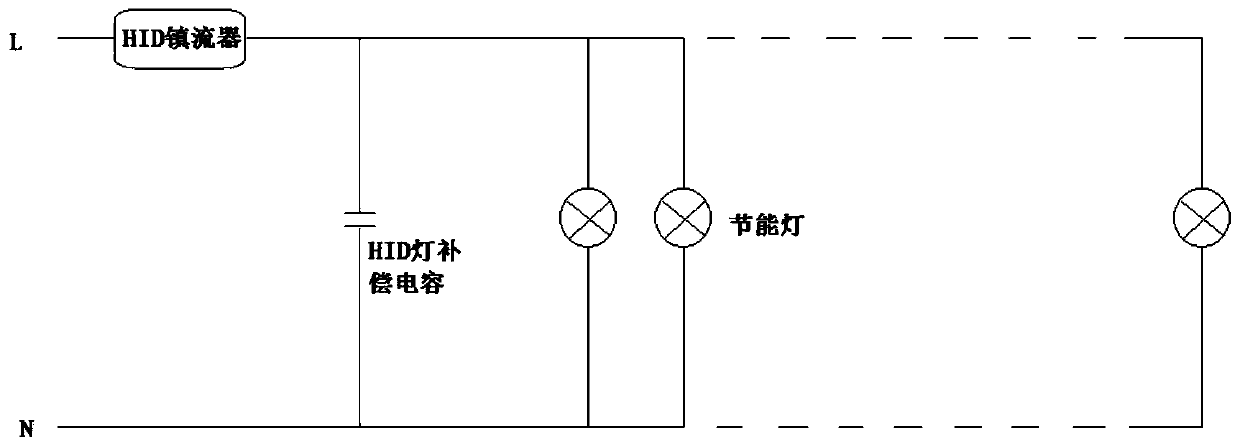

[0025] The technical solution of the embodiment of the present invention is: firstly, the mature nano-reflective technology is used to fully exploit the efficiency of the existing lamps. The traditional lighting source has a 360° full-scale light emission. Reflected back, however, the metal reflectors used in ordinary lamps are prone to rapid aging due to the influence of external light, etc., resulting in yellowing and darkening, which greatly reduces the reflection efficiency, which makes the actual efficiency of many existing lamps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com