On site antistatic terrazzo ground construction method

A construction method, terrazzo technology, applied to floors, insulation layers, buildings, etc., can solve problems such as high construction costs, reduced floor clearance, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

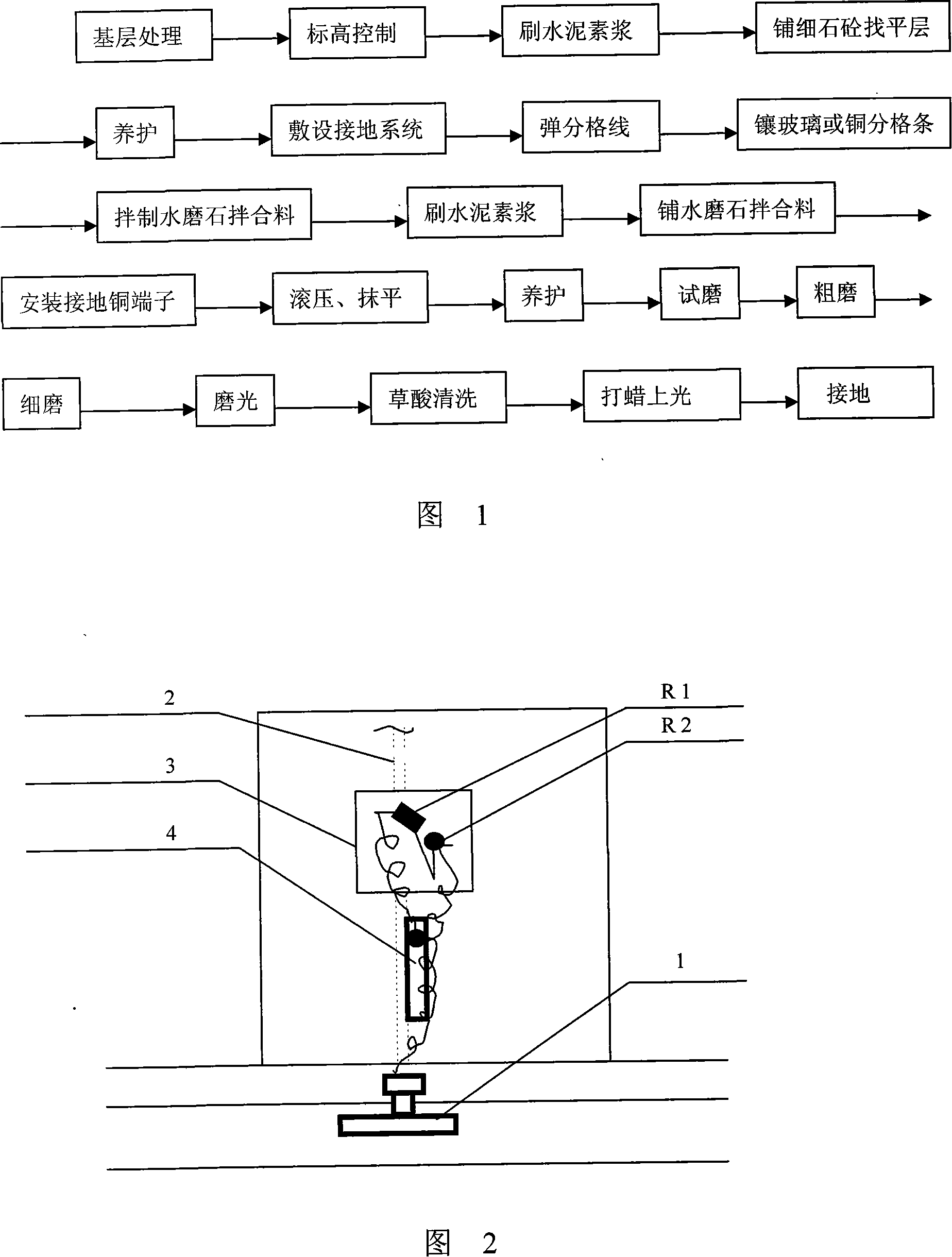

[0013] Embodiment 1: as shown in Figure 1, construct according to the following steps:

[0014] The first is construction preparation:

[0015] 1. The plastering of the ceiling and walls has been completed and accepted, and the waterproof layer of the roof has been completed.

[0016] 2. The acceptance of the basic structure is completed, the indoor wall surface is bounced to the +50cm horizontal standard line, the door frame is installed and protected, and the installation is completed. .

[0017] 3. Before the construction of the surface layer, the cushion layer and the waterproof layer should be prepared, and the thickness of the terrazzo should be reserved according to the elevation, at least 30mm, and the concealed acceptance should be done.

[0018] 4. The terrazzo slurry is discharged in an organized manner, and the floor is equipped with a slurry discharge pipe, and the terrazzo slurry is discharged to the outdoor slurry discharge pit.

[0019] 5. Base-level cleanin...

Embodiment 2

[0074] Embodiment 2: In this embodiment, the volume ratio of cement and gravel in the terrazzo mixture is 1:1.5, and the others are the same as in Embodiment 1.

Embodiment 3

[0075] Embodiment 3: In this embodiment, the volume ratio of cement and gravel in the terrazzo mixture is 1:2.5, and the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com