Cast-in-place inorganic artificial terrazzo floor-on-grade and construction method thereof

A construction method and terrazzo technology, which are applied in building structures, buildings, floors, etc., can solve the problems of excessive waste water, easy ash formation on the ground, low strength, etc., and achieve the effects of convenient use, simple structure and uniform texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

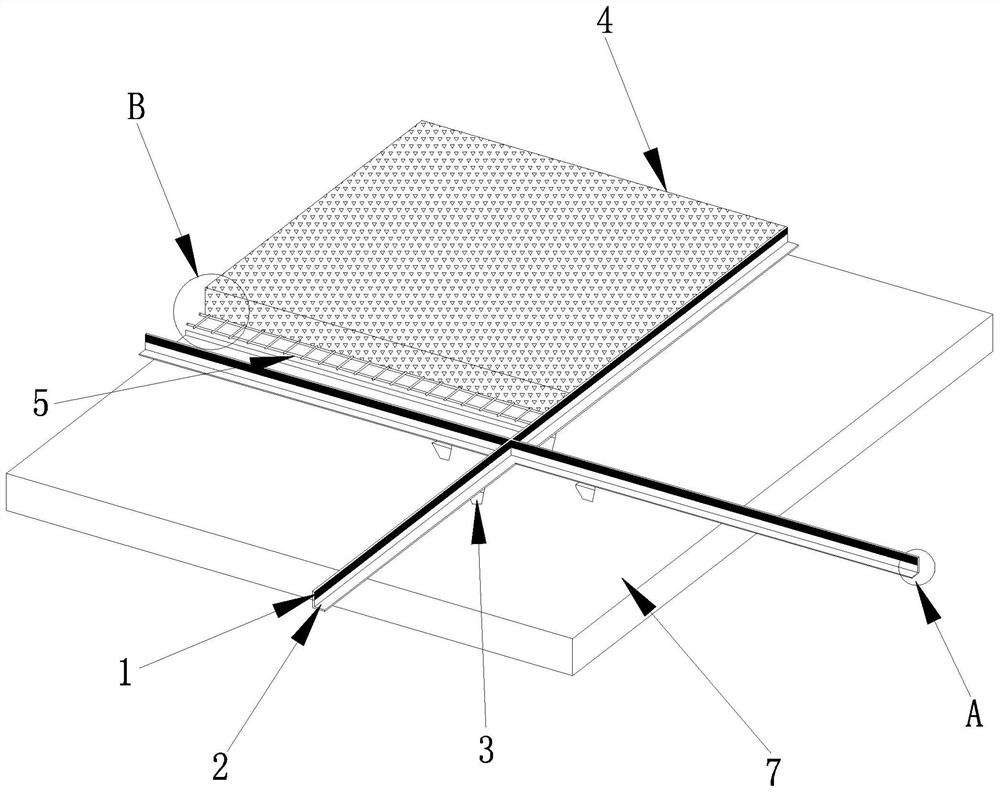

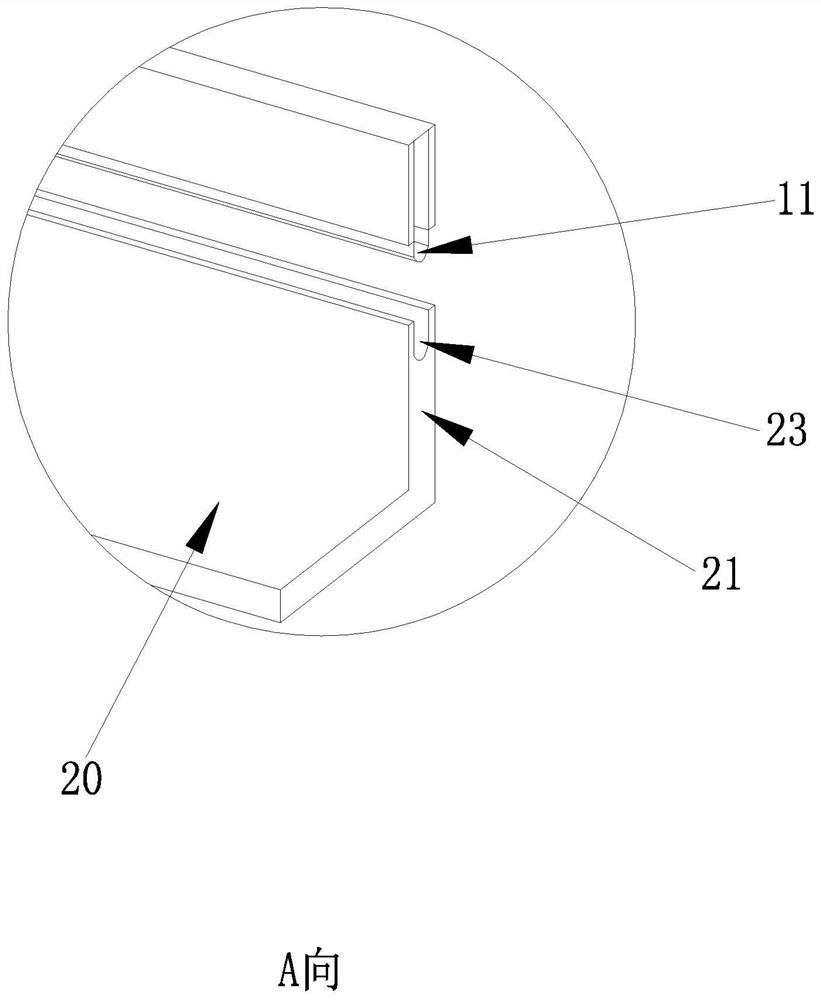

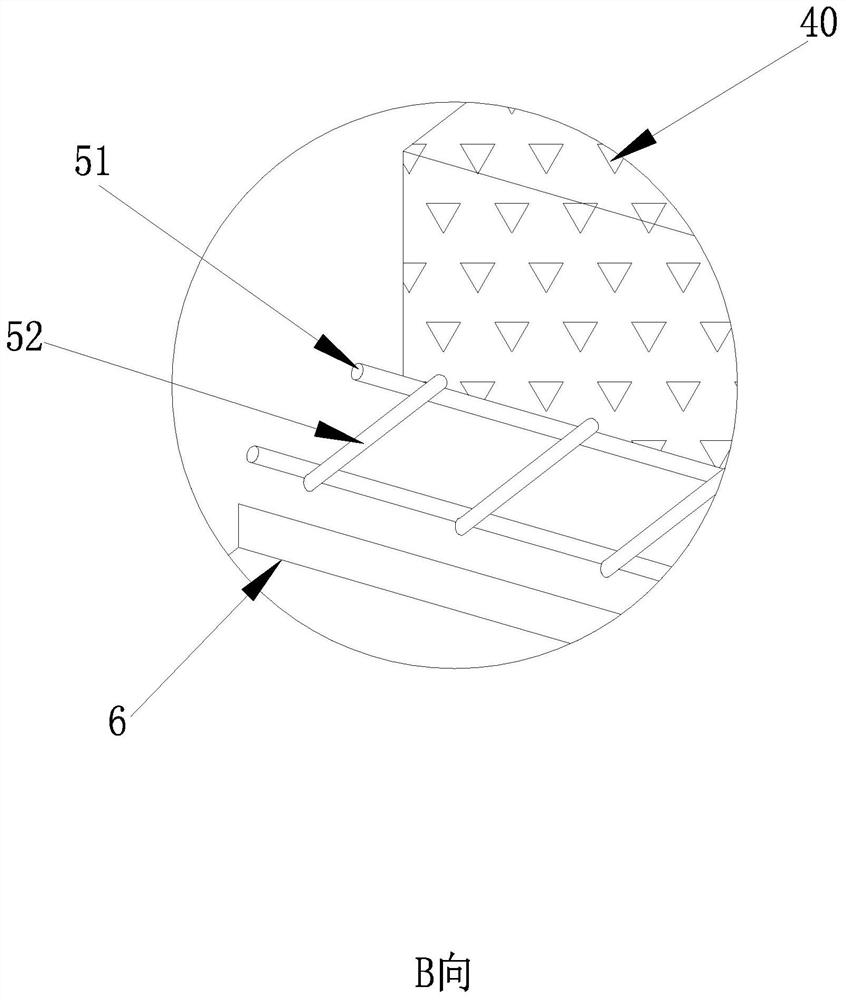

[0039] Such as Figure 1-3As shown; the present embodiment provides a cast-in-situ inorganic artificial terrazzo floor, including several layers of concrete bases 4 assembled on the building ground 7; the building ground 7 is also equipped with several layers of concrete bases 4 for dividing The division mechanism; several layers of concrete base 4 are laid with grid-like reinforcement mesh 5; There are copper strips 1; a number of wooden wedges 3 are equidistantly arranged on the building ground 7, and the wooden wedges 3 and the building ground 7 are fastened by screws; the structure of the invention is simple and easy to use, and the terrazzo floor is poured with concrete base on site Finally, it is ground with special machinery to obtain a floor surface with uniform texture, bright and delicious, and durable. For the functionality, aesthetics, and environmental protection of inorganic artificial terrazzo floors, it can achieve different functions and uses of different user...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com