Epoxy self-leveling floor with concrete sealing curing agent and construction method thereof

A technology of sealing curing agent and construction method, applied in the direction of floor, building, building structure, etc., can solve the problems of long construction interval and high construction conditions of concrete base, so as to improve the service life, improve the overall appearance, and improve the flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

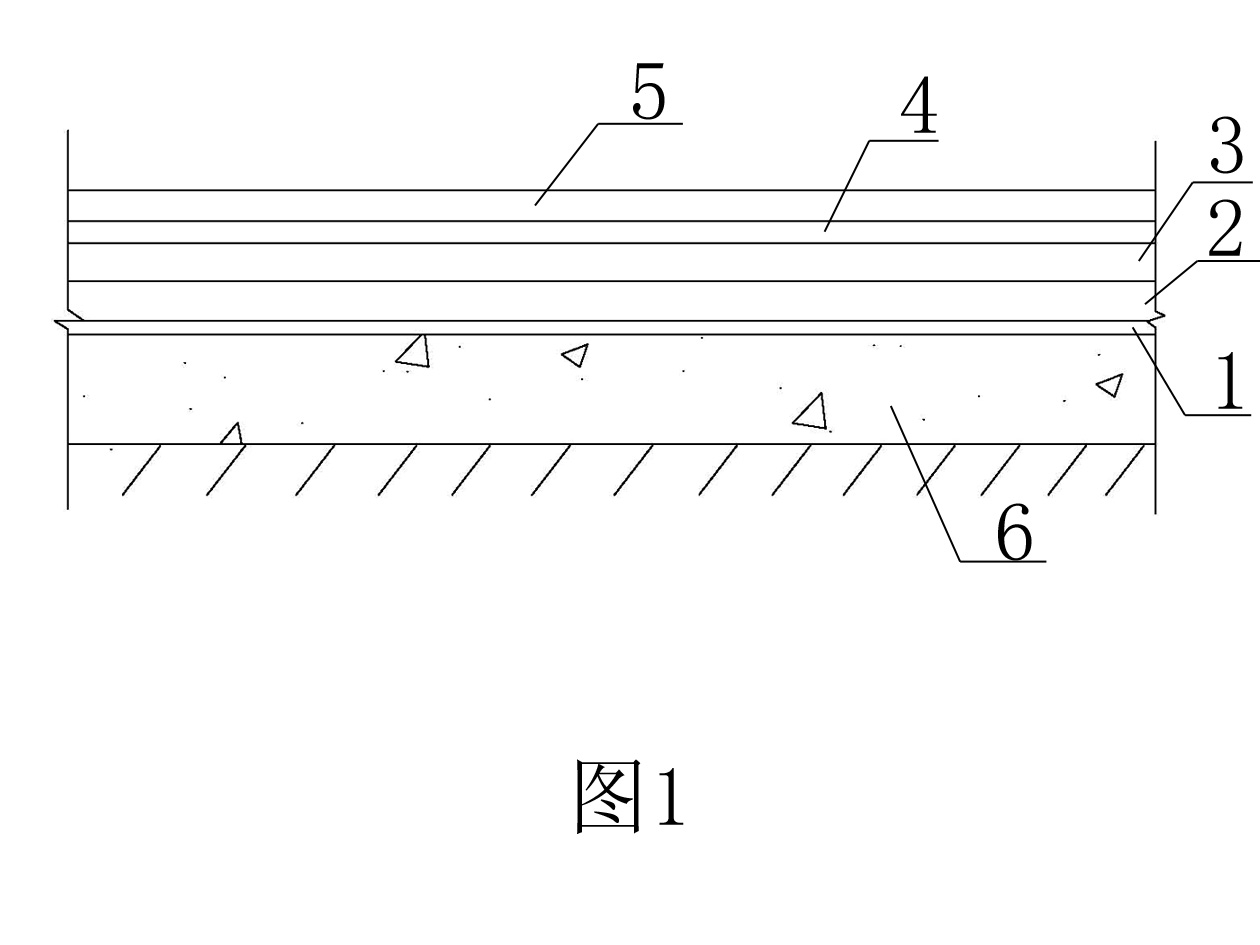

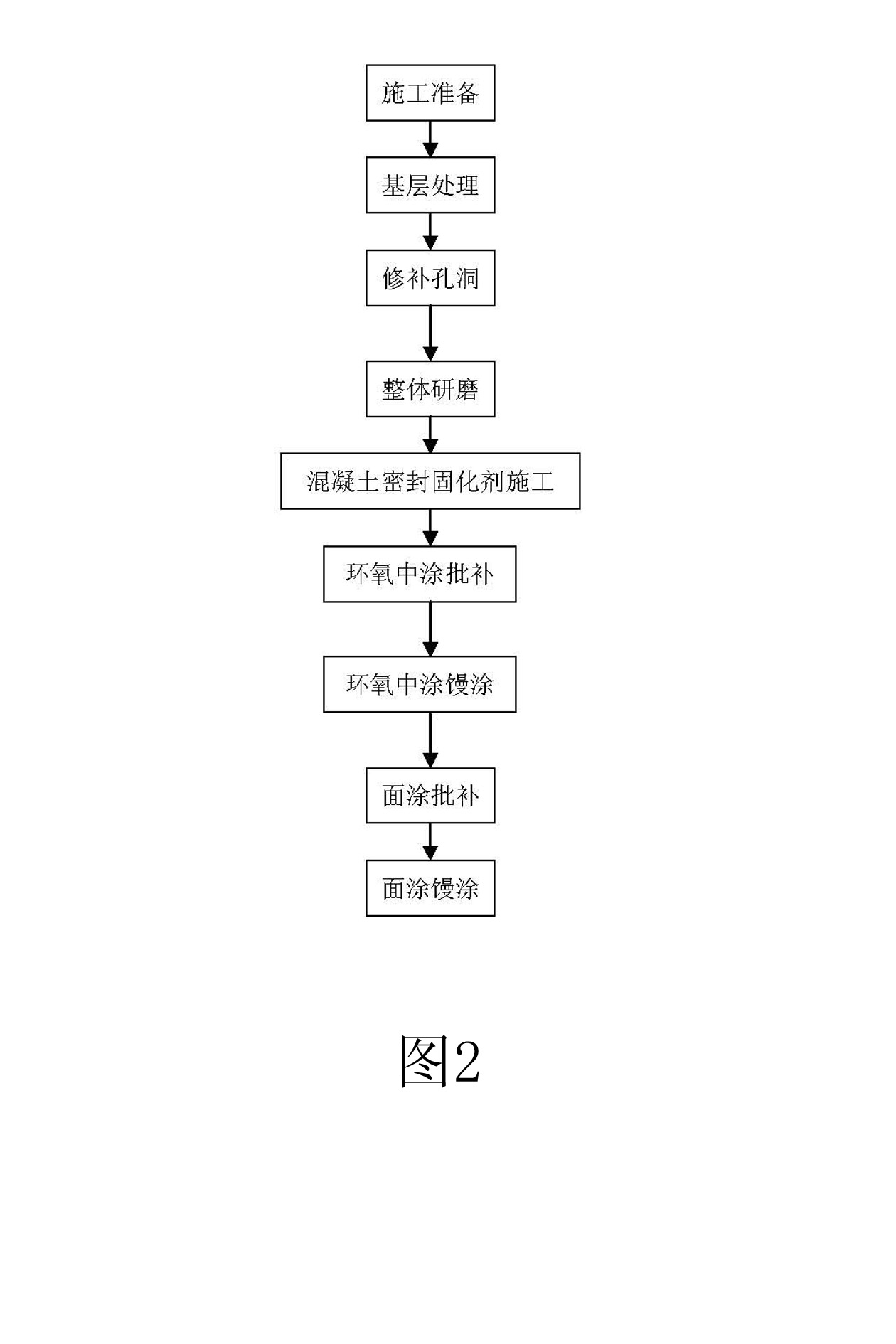

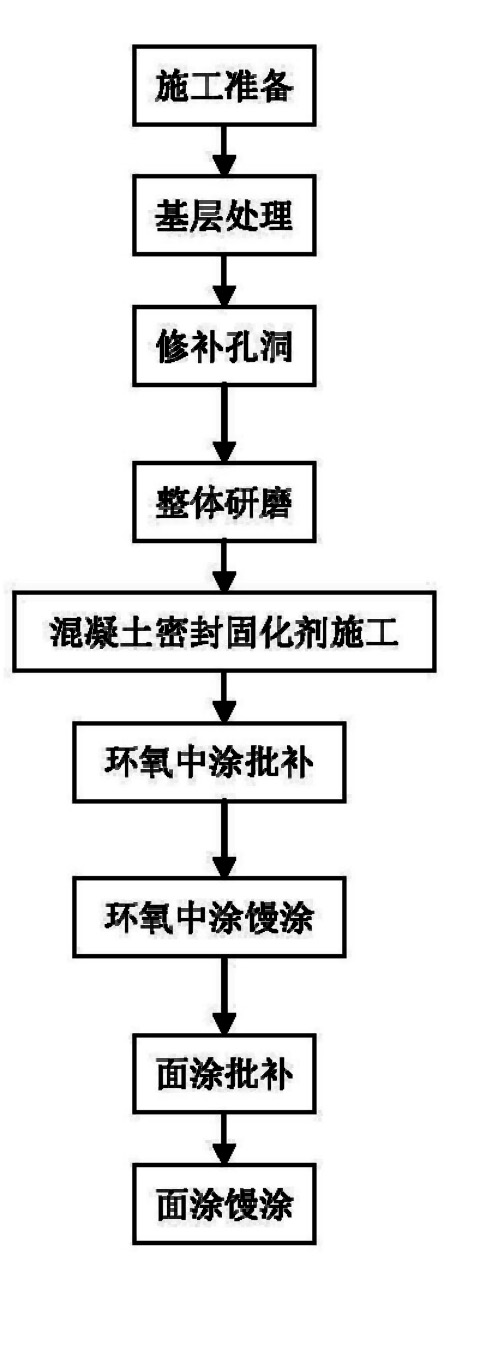

[0033] The embodiment is shown in Fig. 1, a concrete sealing and curing agent epoxy self-leveling ground, which is constructed on the concrete base 6, and from bottom to top is the concrete base 6, the lower coating 1, and the intermediate coating 2, Middle coat 3, top coat repair layer 4 and top coat 5, the under coat 1 is a concrete seal curing agent coating, the concrete seal curing agent penetrates into the concrete base and combines with it, the middle coat 3 And the top coat 5 is an epoxy paint layer, and the patch patch layer 2 and the top patch patch layer 4 are a mixture of epoxy paint, epoxy paint curing agent and additives.

[0034] The additive is quartz powder or quartz sand.

[0035] The epoxy paint of the middle coat 3 and the middle coat patch 2 is epoxy mortar floor paint, and the epoxy paint of the top coat patch 4 and the top coat 5 is epoxy self-leveling floor paint.

[0036] The sum of the thicknesses of the middle coat patch layer 2, middle coat layer 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com