Recycling method for cast-in-situ terrazzo floor polishing waste slurry

A recovery method and waste slurry technology, applied in separation methods, chemical instruments and methods, filtration circuits, etc., to reduce manpower input, save costs, and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

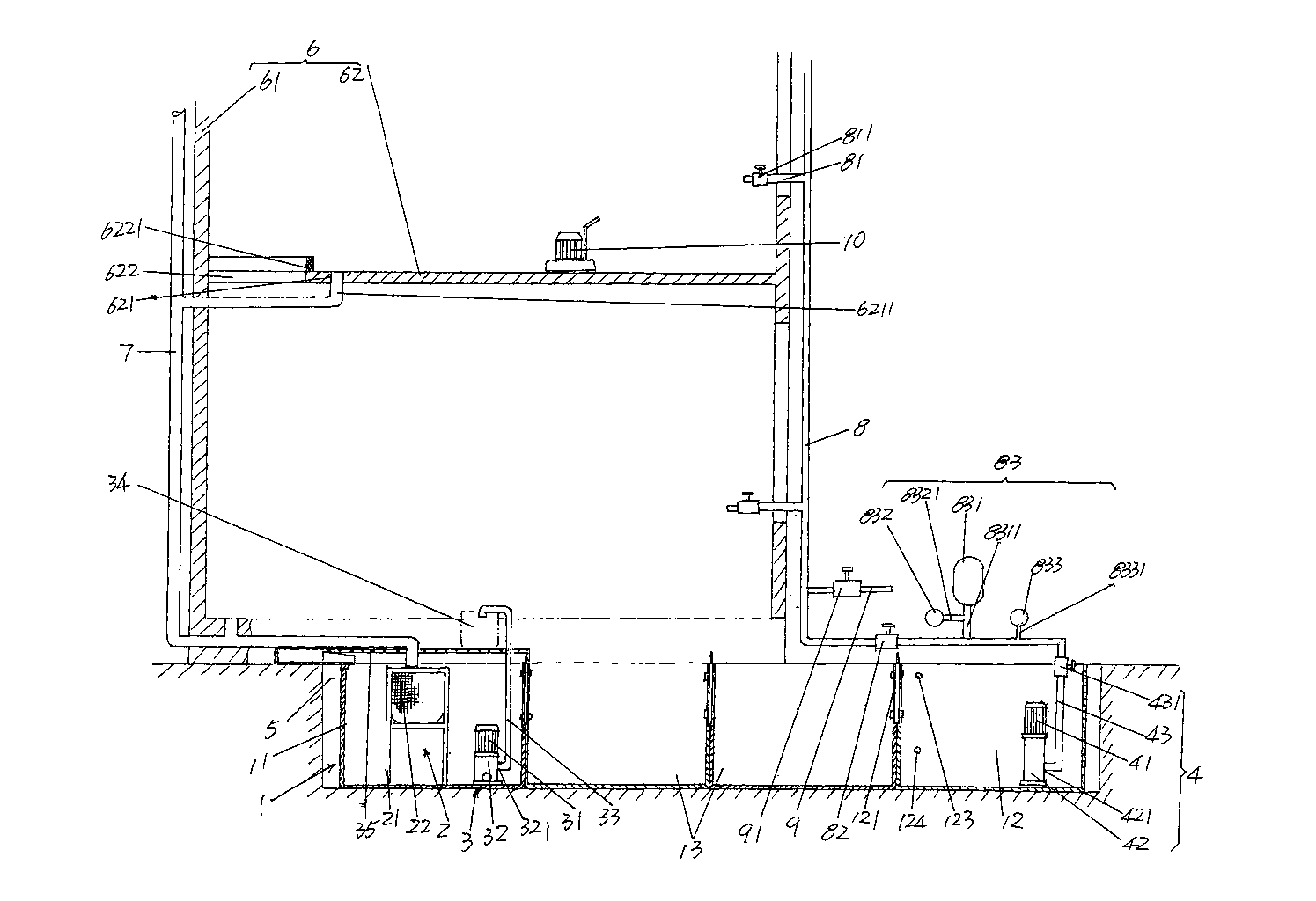

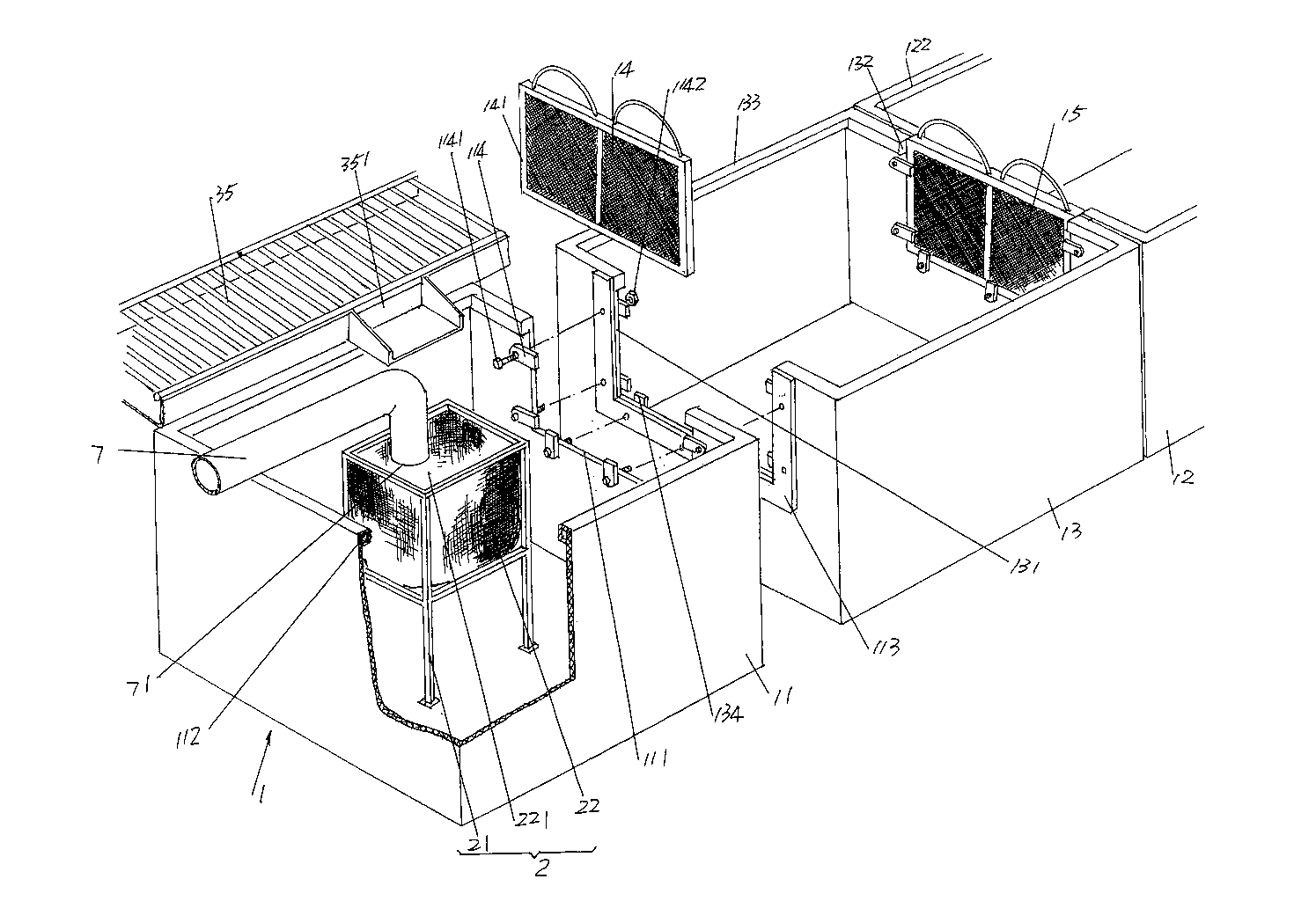

[0028] See figure 1 with figure 2 The recovery method of the cast-in-place terrazzo floor polishing waste slurry provided by the present invention comprises the following steps:

[0029] A) Preliminary preparation, equipped with a waste slurry collection, filtration, sedimentation and separation mechanism 1, the waste slurry collection, filtration, precipitation and separation mechanism 1 includes a waste slurry collection box 11, a clean water reuse box 12 and a sedimentation box 13. In this embodiment, The height of the waste slurry collection tank 11, the clear water reuse tank 12 and the sedimentation tank 13 is preferably 1 m, and the length and width are 1.5 m, and they are all preferably made of glass fiber reinforced plastic. In order to ensure the strength and reflect a good reuse rate, the upper edge around the inner wall of the waste slurry collection box 11 is wrapped with a first reinforcing rib 112, and the upper edge around the inner wall of the clean wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com