Colorful terrazzo floor brick and production method thereof

A production method and technology of floor tiles, which are applied in chemical instruments and methods, grinding machines, grinding/polishing equipment, etc., can solve the problems of long processing time, heavy weight, and high cost of colored patterned terrazzo floor tiles, and achieve pattern diversity, The effect of strong market competitiveness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

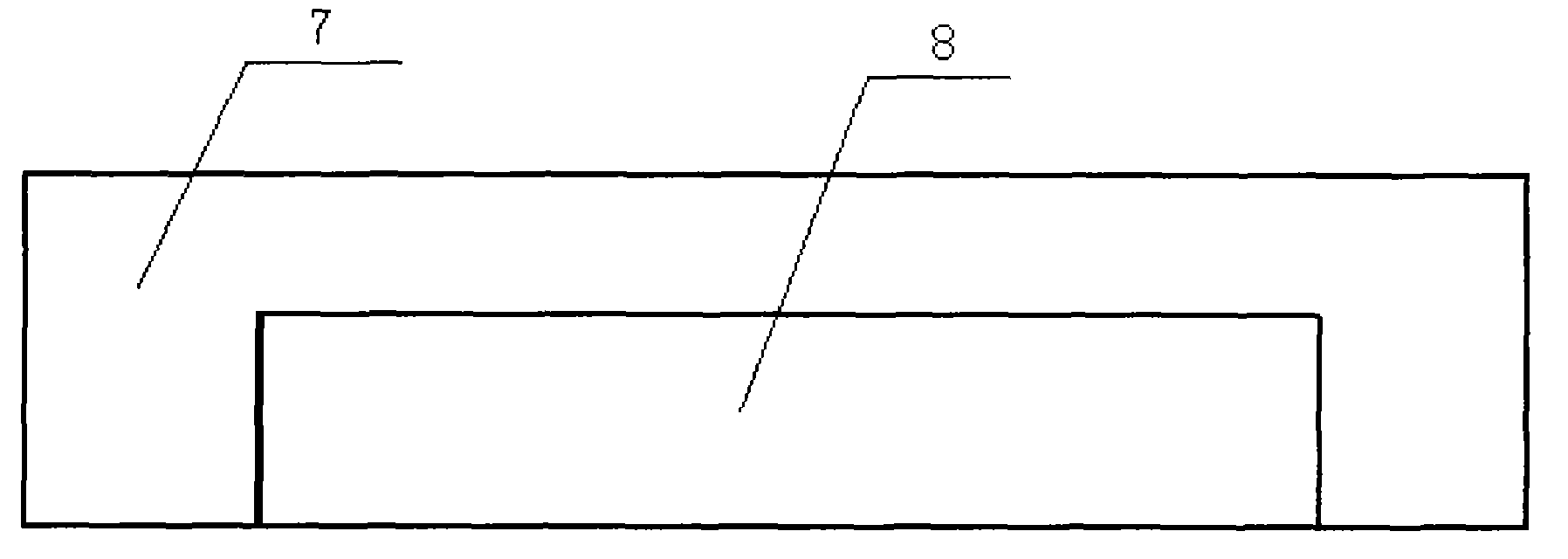

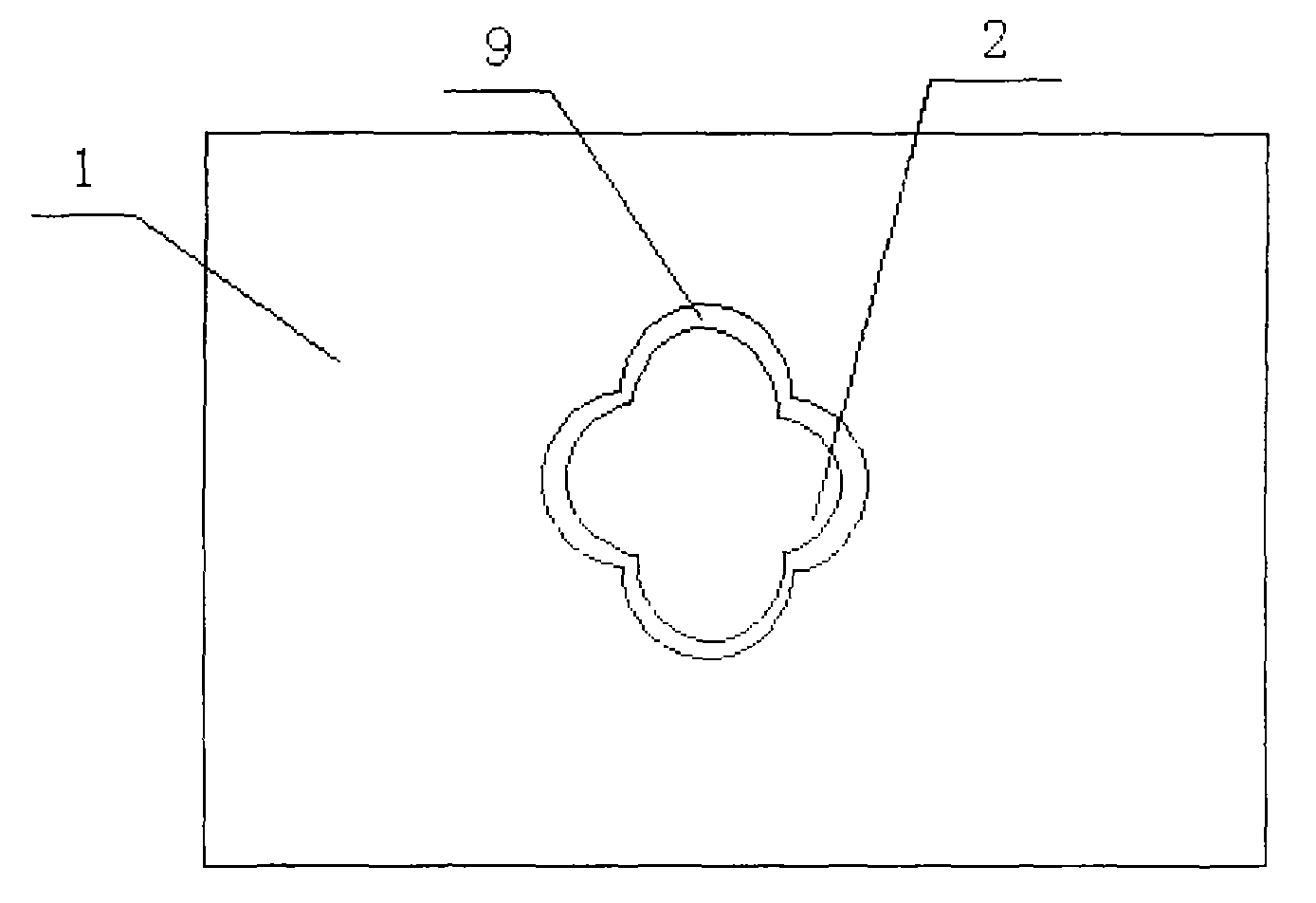

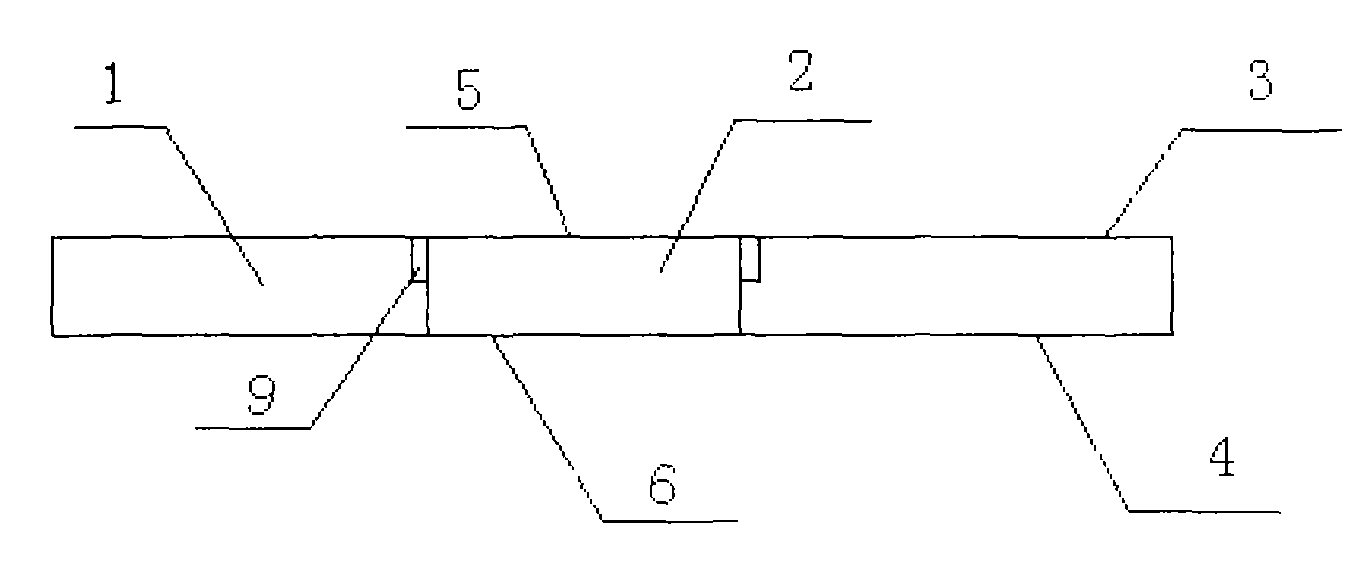

[0030] figure 1 It is a structural schematic diagram of the prior art colored terrazzo floor tiles. The colored terrazzo floor tiles in the prior art are composed of a base plate 7 and colored terrazzo blocks 8, and the colored terrazzo blocks 8 are embedded in the middle of the base plate 7. The colored terrazzo floor tiles of this structure need to form the colored terrazzo blocks 8 first, and then the colored terrazzo blocks 8 must be formed. Put the terrazzo block 8 into the center of the bottom of the terrazzo floor tile mold of a certain specification, and fill the ingredients composed of white cement, marble stones, pigments and water around and on the top of the colored pattern terrazzo block. After shaking, fill the top of the ingredients. Pack the ingredients composed of ordinary cement, sand and water, smooth it, demould it, keep it healthy for 96-120 hours, and finally make it into colorful patterned terrazzo floor tiles through rough grinding and fine grinding. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com