Photosensitive controllable rapid-hardening concrete pouring material and construction method thereof

A rapid hardening, pouring material technology, applied in construction, bridges, erection/assembly of bridges, etc., can solve problems such as inability to control when hardening and hardening speed, long cycle, interruption of traffic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

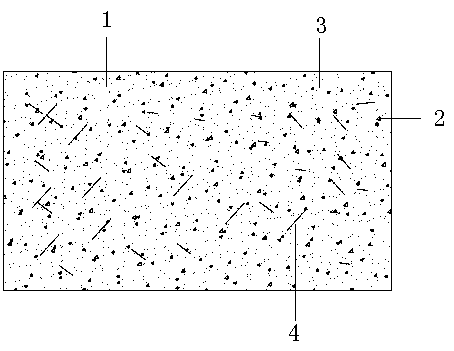

[0018] Implementation example figure 1 As shown, the photosensitive, controllable and rapid hardening concrete castable of the present invention includes shadowless glue 1, transparent stone or broken glass aggregate 2, sand 3 and glass fiber 4, and transparent stone or broken glass aggregate 2, sand 3 and The glass fiber 4 is evenly stirred and then mixed into the shadowless glue 1, and the castable is obtained after sufficient stirring.

[0019] Preferably, the shadowless glue 1: sand 3: aggregate 2: glass fiber 4=1: 2.0-3.5: 3.0-4.5: 0.2-0.5 in the castable, wherein the sand 3 and the aggregate 2 are in a dry state.

[0020] The proportion of each material component in the castable can be designed with reference to the theory of the mixing ratio of different strength grades of concrete, and the shadowless glue can be proportioned according to the proportion of cement and water in the concrete of different strength grades.

[0021] A construction method of the above pouring materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com