Waste glass self-luminous aggregate concrete decorative material and preparation method thereof

A technology for waste glass and decorative materials, which is applied in the field of waste glass self-luminous aggregate concrete decorative materials and its preparation, and can solve the problems of high sintering temperature and easy introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

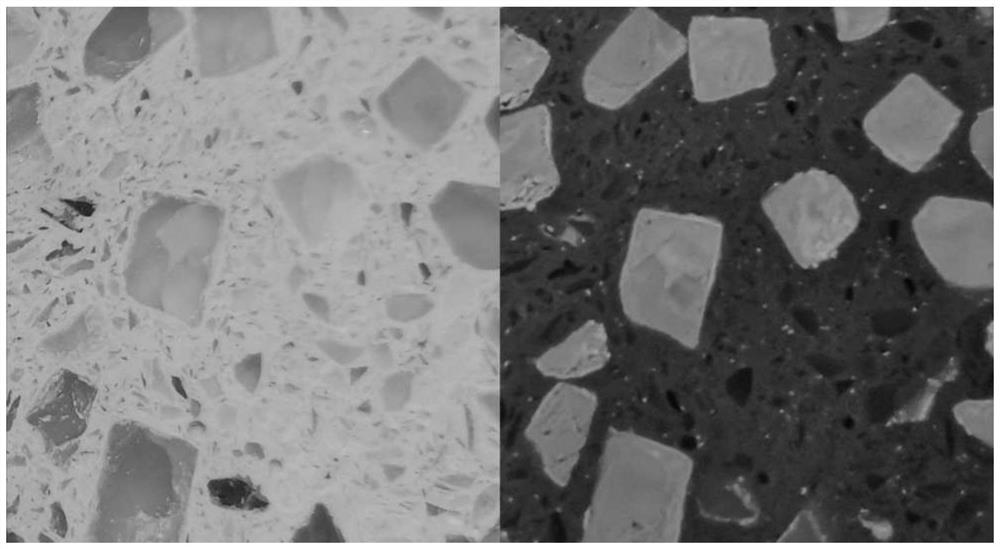

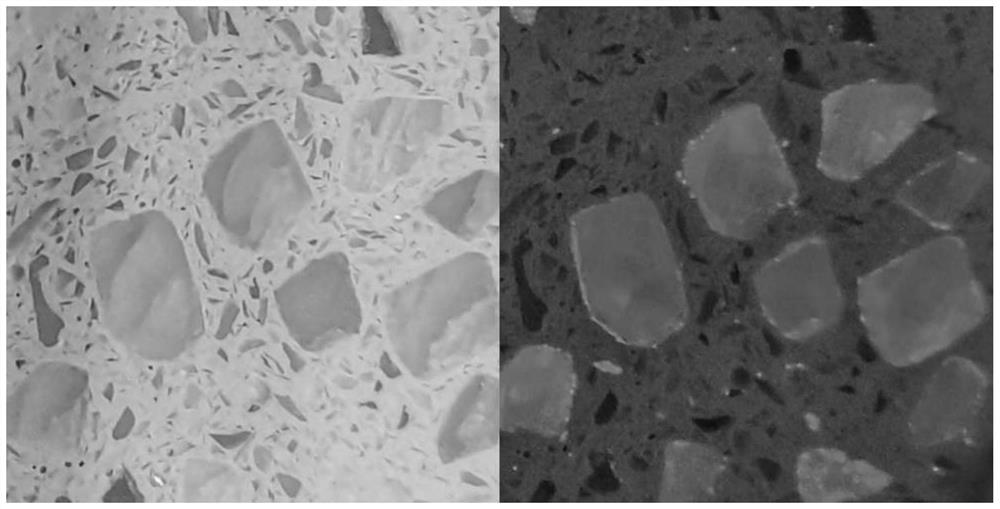

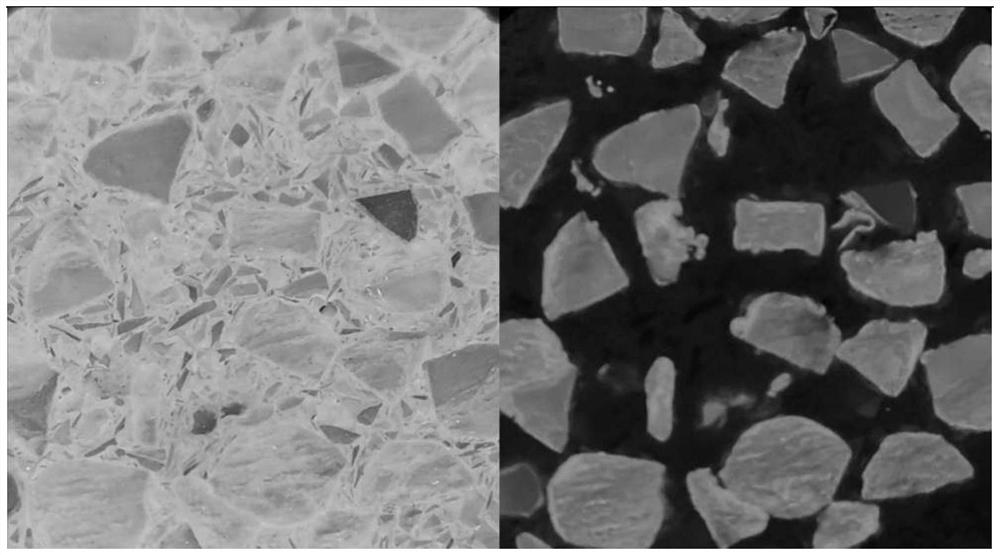

Image

Examples

Embodiment 1

[0020] A waste glass self-luminous aggregate concrete decoration material and a preparation method thereof, specifically comprising the following steps:

[0021] Step 1: washing, crushing and sieving waste glass, and dividing them into fine glass (d less than 2.36mm) and coarse glass (d=5mm-10mm) according to particle size.

[0022] Step 2: Weigh the adhesive and glass particles (d=5mm-10mm) according to the mass ratio of adhesive:glass=1:5, mix and stir evenly.

[0023] Step 3: Weigh the long-lasting luminescent material according to the ratio of long-lasting luminescent material:adhesive = 1:3, coat the long-lasting luminescent material on the glass adhesive mixture in step 2, and naturally cure it at room temperature for two days to form self-luminous glass aggregate.

[0024] Step 4: According to the ratio in Table 2, weigh the gelling material, admixture, long-lasting luminescent material, luminescent glass aggregate, non-luminescent aggregate, and water, and add them to...

Embodiment 2

[0030] A waste glass self-luminous aggregate concrete decoration material and a preparation method thereof, specifically comprising the following steps:

[0031] Step 1: washing, crushing and sieving waste glass, and dividing them into fine glass (d less than 2.36mm) and coarse glass (d=5mm-10mm) according to particle size.

[0032] Step 2: Weigh the adhesive and glass particles (d=5mm-10mm) according to the mass ratio of glass:adhesive=5:1, mix and stir evenly.

[0033] Step 3: Weigh the long-lasting luminescent material according to the ratio of long-lasting luminescent material:adhesive = 1:3, coat the long-lasting luminescent material on the glass adhesive mixture in step 2, and naturally cure it at room temperature for two days to form self-luminous glass aggregate.

[0034] Step 4: According to the ratio in Table 3, weigh the cementitious material, admixture, glass aggregate, luminous glass aggregate, and water, and add them into a stirring container at the same time, s...

Embodiment 3

[0040] A waste glass self-luminous aggregate concrete decoration material and a preparation method thereof, specifically comprising the following steps:

[0041] Step 1: washing, crushing and sieving waste glass, and dividing them into fine glass (d less than 2.36mm), medium glass (d=2.36mm-5mm) and coarse glass (d=5mm-10mm) according to particle size.

[0042] Step 2: Weigh the adhesive and glass particles according to the mass ratio of glass:adhesive=5:1, mix and stir evenly.

[0043] Step 3: Weigh the long-lasting luminescent material according to the ratio of long-lasting luminescent material:adhesive = 1:3, coat the long-lasting luminescent material on the glass adhesive mixture in step 2, and naturally cure it at room temperature for two days to form a luminescent glass bone material.

[0044] Step 4: According to the ratio in Table 4, weigh the gelling material, admixture, long-lasting luminescent material, luminescent glass aggregate, non-luminescent aggregate, and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com