Method for harmlessly treating cyaniding tailings by utilizing microcrystalline glass granule surface crystallization process

A technology of cyanide tailings and glass-ceramics, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of limited demand and achieve comprehensive utilization and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

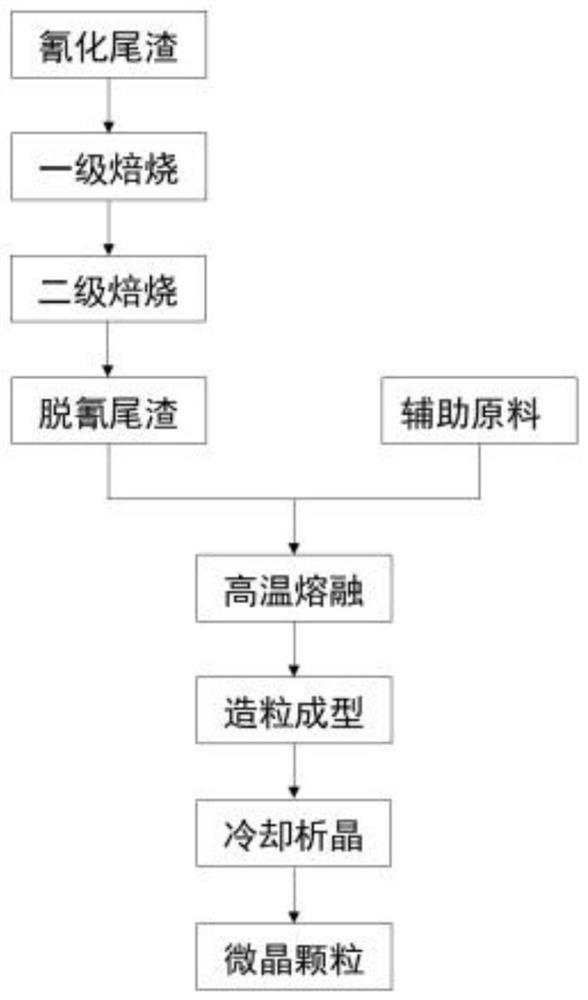

Image

Examples

Embodiment 1

[0053] Cyanide tailings (moisture content 10%) after pressure filtration and dehydration are dispersed by a disperser (feeding particle size is 20mm).

[0054] Transport the broken cyanide tailings material to the rotary kiln for primary roasting at a temperature of 700°C for 30 minutes and a negative pressure of -30kpa to remove part of the cyanide and all of the cyanide in the cyanide tailings moisture.

[0055] The cyanide tailings after the primary roasting are transported to the roasting kiln for secondary roasting. The roasting temperature is 600°C and the time is 90 minutes. The high temperature is fully decomposed, and the decyanation tailings are obtained after the material is cooled, which is transported to the material plant for storage.

[0056] The decyanation tailings are crushed to 3mm by a crusher, the particle size of the auxiliary components is 2mm, the decyanation tailings account for 40.0wt.% of the total weight of raw materials, the auxiliary raw material...

Embodiment 2

[0062] Cyanide tailings (moisture content 15%) after pressure filtration and dehydration are dispersed by a disperser (incoming particle size is 15mm).

[0063] Transport the broken cyanide tailings material to a rotary kiln for primary roasting at a temperature of 750°C for 40 minutes and a negative pressure of -40kpa to remove part of the cyanide and all of the cyanide in the cyanide tailings moisture.

[0064] The cyanide tailings after the primary roasting are transported to the roasting kiln for secondary roasting. The roasting temperature is 500°C and the time is 100 minutes. The high temperature is fully decomposed, and the decyanation tailings are obtained after the material is cooled, which is transported to the material plant for storage.

[0065] The decyanation tailings are crushed to 4mm by a crusher, the particle size of the auxiliary components is 1mm, the decyanation tailings account for 50.0wt.% of the total weight of the raw materials, the auxiliary material...

Embodiment 3

[0071] Cyanide tailings (moisture content 20%) after pressure filtration and dehydration are dispersed by a disperser (incoming particle size is 30mm).

[0072] Transport the dispersed cyanide tailings material to the rotary kiln for primary roasting at a temperature of 800°C for 60 minutes and a negative pressure of -60kpa to remove part of the cyanide and all of the cyanide in the cyanide tailings moisture.

[0073] The cyanide tailings after the primary roasting are transported to the roasting kiln for secondary roasting. The roasting temperature is 800°C and the time is 180 minutes. The high temperature is fully decomposed, and the decyanation tailings are obtained after the material is cooled, which is transported to the material plant for storage.

[0074] The decyanation tailings are crushed to 4mm by a crusher, the particle size of the auxiliary components is 1mm, the decyanation tailings account for 55.0wt.% of the total weight of raw materials, the auxiliary raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com