Asphalt mixture doped with waste glass aggregate and preparation method of asphalt mixture

A technology of asphalt mixture and waste glass, which is applied in the field of road materials, can solve the problems of changing the interlocking structure of the mixture, the decrease of the Marshall stability of the asphalt mixture, and the decline of performance, so as to achieve simple preparation process, promote recycling and reduce production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 12000g of asphalt mixture is used as an example. The raw materials and their dosage are: Sinopec Donghai No. 70 A-grade matrix asphalt 561.0g, 2.36-4.75mm file waste glass aggregate 497.6g, 1.18-2.36mm file waste glass aggregate 394.6g, coarse Aggregate 7223.7g, fine aggregate 2751.1g, ore powder 572.0g; parts by mass are as follows: 4.68 parts of base asphalt, 4.15 parts of 2.36-4.75mm grade waste glass aggregate, 3.28 parts of 1.18-2.36mm grade waste glass collection material, 60.19 parts of coarse aggregate, 22.93 parts of fine aggregate, and 4.77 parts of mineral powder.

[0025] The particle size of waste glass aggregate is greater than 1.18mm and less than 4.75mm; including A with a particle diameter greater than 2.36mm and less than 4.75mm, and B with a particle diameter greater than 1.18mm and less than or equal to 2.36mm, and the mass ratio of A and B is: 29: twenty three. The mineral powder is limestone mineral powder and the particle size of the mineral powd...

Embodiment 2

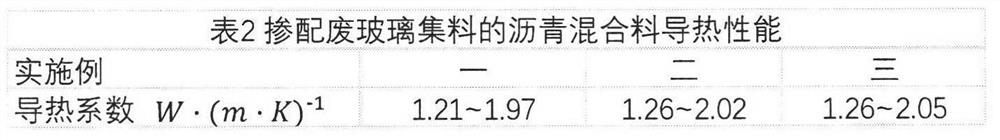

[0033] 12000g of asphalt mixture is taken as an example. The raw materials and their dosage are: 561.0g of Sinopec Donghai No. 70 Grade A matrix asphalt, 331.7g of waste glass aggregates of 2.36-4.75mm, 263.1g of waste glass aggregates of 1.18-2.36mm, coarse Aggregate 7389.6g, fine aggregate 2882.6g, mineral powder 572.0g; parts by mass are as follows: 4.68 parts of matrix pitch, 2.76 parts of 2.36-4.75mm grade waste glass aggregate, 2.19 parts of 1.18-2.36mm grade waste glass collection material, 61.58 parts of coarse aggregate, 24.02 parts of fine aggregate, and 4.77 parts of mineral powder. The preparation method of the above-mentioned raw materials and mixture is the same as that of Example 1. The pavement performance and thermal conductivity of the asphalt mixture mixed with waste glass aggregate prepared in this way are shown in Table 1 and Table 2.

Embodiment 3

[0035] 12000g of asphalt mixture is used as an example. The raw materials and their dosage are: 561.0g of Sinopec Donghai brand No. 70 A-grade matrix asphalt, 165.9g of waste glass aggregates of 2.36-4.75mm, 131.5g of waste glass aggregates of 1.18-2.36mm, coarse Aggregate 7555.5g, fine aggregate 3014.2g, ore powder 572.0g; parts by mass are as follows: 4.68 parts of base asphalt, 1.38 parts of 2.36-4.75mm grade waste glass aggregate, 1.09 parts of 1.18-2.36mm grade waste glass collection material, 62.96 parts of coarse aggregate, 25.12 parts of fine aggregate, and 4.77 parts of mineral powder. The preparation method of the above-mentioned raw materials and mixture is the same as that of Example 1. The pavement performance and thermal conductivity of the asphalt mixture mixed with waste glass aggregate prepared in this way are shown in Table 1 and Table 2.

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com