Micro-surfacing pavement material and preparation method thereof

A pavement material and micro-surface technology, applied in the field of micro-surface pavement materials and their preparation, can solve problems such as insufficient anti-skid performance and increased noise, achieve rich angularity, improve structural depth, and stabilize anti-skid and wear-resistant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

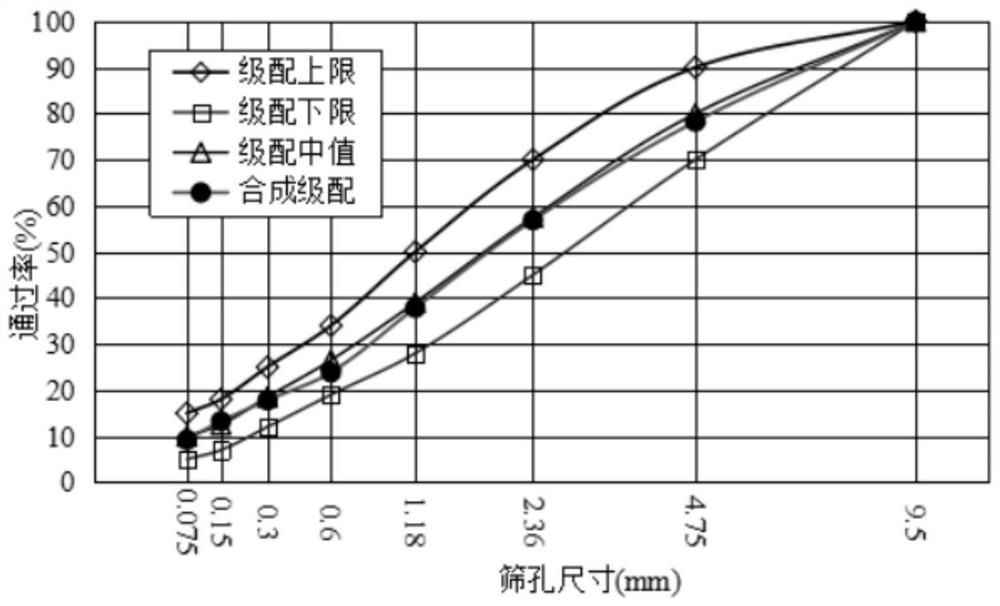

Image

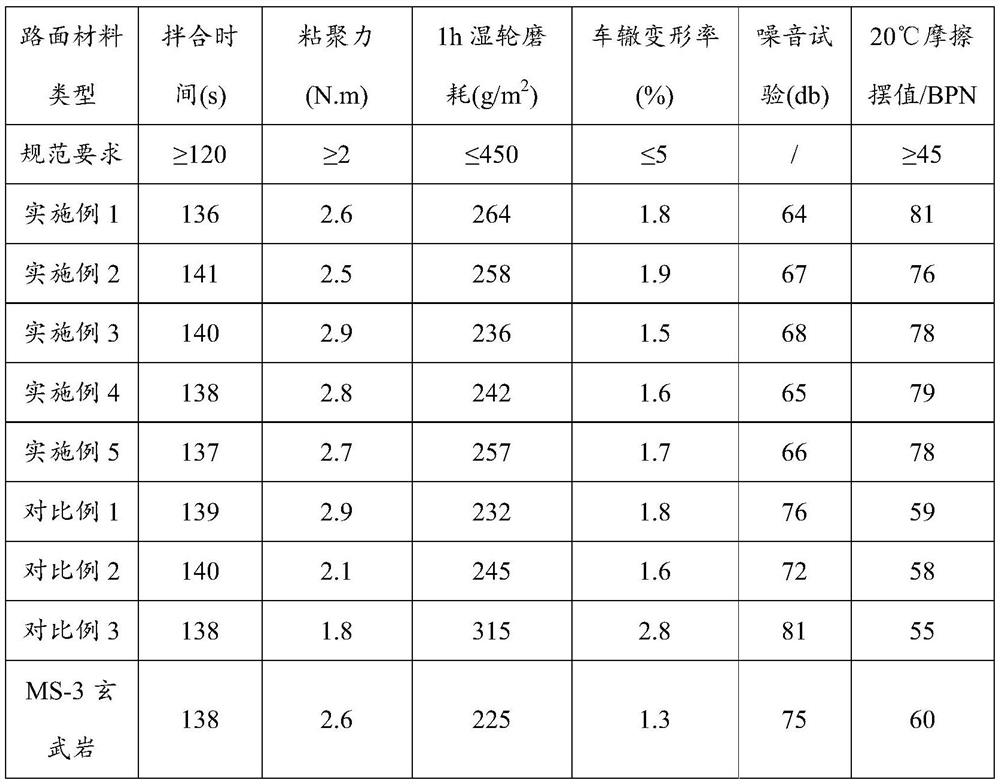

Examples

Embodiment 1

[0024]The micro-surface material of the present embodiment includes a collector, SBR modified emulsified asphalt and water, the collector, the SBR modified emulsified asphalt and the water mass ratio of 1: 0.07: 0.06; The assembly is calculated according to the percentage of mass, and the group is: a particle size of 4.75-9.5mm steel slag collective is 22%, the particle size is 2.36-4.75mm waste glass and steel slag aguate 10% and 13%, and the particle size is 0-2.36 mm Steel slag aggregates and rubber particles were 46% and 3%, respectively, and the mine powder was 4.5%, and the silicate cement was 1.5%.

[0025]The method for preparing the pavement material in this embodiment, including: according to each group distribution ratio, the steel slag coarse material, steel slag fine collector, glass collector, rubber particles, and filler mixed 30s to uniform, then add Water mixed 34S to uniform moist, then add SBR modified emulsified asphalt mixing 30s to uniformly obtained the microfubu...

Embodiment 2

[0027]The difference between the present embodiment and the first embodiment is only the mass percentage of the aggregates, specifically, the assembly is calculated according to the mass percentage, the particle size is 2.2%, the particle size is 2.36-4.75mm waste glass. And the steel slag agu is 8% and 15%, respectively, the particle size of 0-2.36 mm, and the rubber rubber particles are 47% and 2%, respectively, the mine powder is 4.5%, and the silicate cement is 1.5%.

Embodiment 3

[0029]The difference between the present embodiment and the first embodiment is only the mass percentage of the aggregates, specifically, the assembly is calculated according to the mass percentage, the particle size is 2.2%, the particle size is 2.36-4.75mm waste glass. And the steel slag aggregates were 6% and 17%, respectively, and the particles of the steel slag aggregate and the waste rubber particles were 48% and 1%, respectively, the mine powder was 4.5%, and the silicate cement was 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com