Novel concrete-filled steel tube composite column filled with steel slag and waste glass concrete and preparation method thereof

A steel pipe concrete and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of ductility, cold formability, weldability, corrosion resistance inferior to austenitic stainless steel, high price, low strength, etc., and achieve saving Effects of natural resources, good economic durability, ductility and improved fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

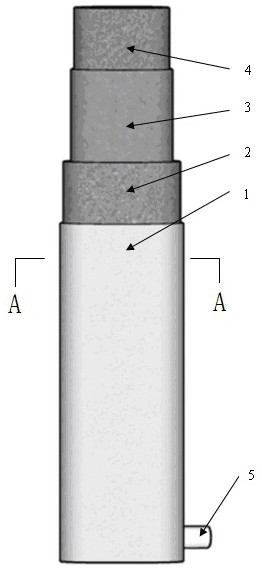

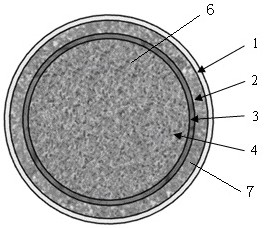

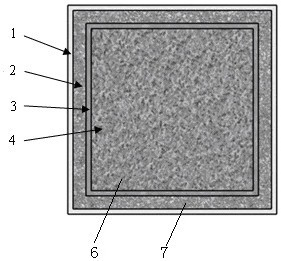

[0035] The novel concrete-filled steel tube composite column filled with steel slag waste glass concrete of the present invention comprises a stainless steel outer steel tube 1 and a carbon steel inner steel tube 3 concentrically arranged inside the stainless steel outer steel tube, and the diameter of the carbon steel inner steel tube 3 is smaller than that of the stainless steel outer steel tube 1 diameter, the inner cavity 6 formed in the carbon steel inner steel pipe 3 is poured with steel slag and waste glass aggregate concrete 4, and the ring space formed between the carbon steel inner steel pipe 3 and the stainless steel outer steel 1 The cavity 7 is poured with steel slag lightweight aggregate concrete 2 .

[0036] The lower part of the stainless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com