Fine glass aggregate light permeable concrete and preparation method thereof

A light-transmitting concrete and fine aggregate technology, applied in the field of building materials, can solve the problems of resource consumption of natural sand and gravel resources, recycling of waste glass, etc., and achieve the effects of reducing consumption, improving the gloss of the surface layer, and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

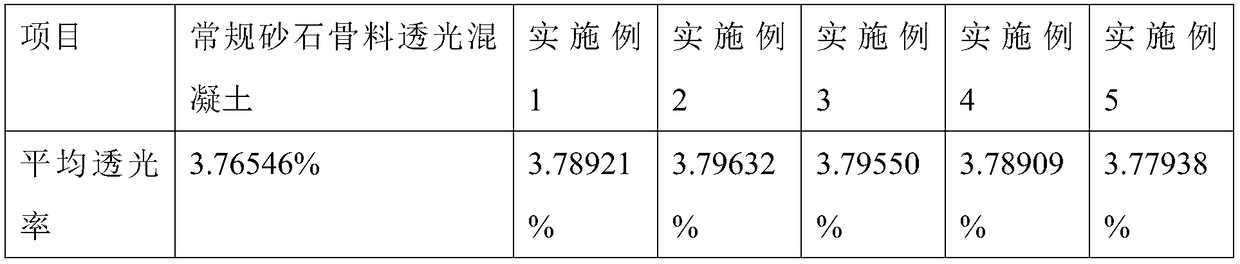

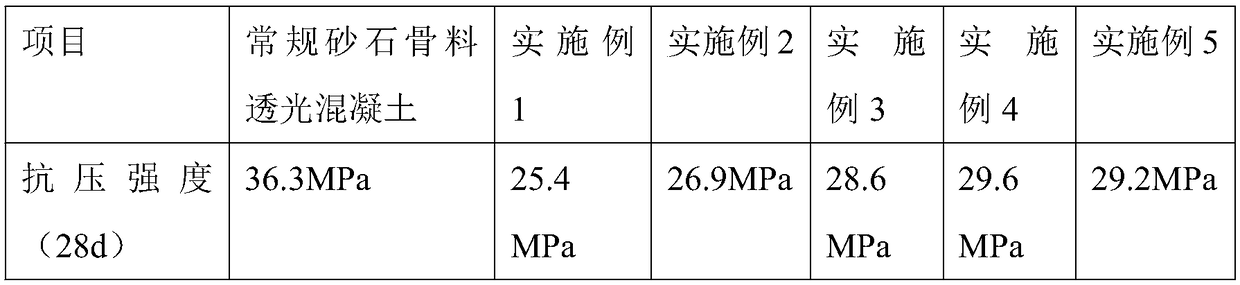

Examples

Embodiment 1

[0021] A method for preparing glass fine aggregate light-transmitting concrete, comprising the following steps:

[0022] (1) Optical fiber layout and mold preparation: use the microcomputer program to operate the drilling machine, drill holes on the rubber base plate, so that the rubber base plate forms a set pattern composed of countless small holes, and then make a circular section with a specific diameter and length The plastic optical fiber is inserted into the small holes on the plastic base plate, and then the carpenter builds the mold around the plastic base plate covered with optical fibers to complete the preparation of the light-transmitting concrete mold;

[0023] (2) Glass fine aggregate preparation: (each time) weigh 5Kg waste glass, after simple manual crushing, pour it into the SM-500 cement test ball mill, pour it out after grinding for 2 minutes, sieve, and keep a 4.75mm sieve undersieve;

[0024] (3) Weigh raw materials by weight: water: 135 parts, PO42.5R c...

Embodiment 2

[0027] A method for preparing glass fine aggregate light-transmitting concrete, comprising the following steps:

[0028] (1) Optical fiber layout and mold preparation: use the microcomputer program to operate the drilling machine, drill holes on the rubber base plate, so that the rubber base plate forms a set pattern composed of countless small holes, and then make a circular section with a specific diameter and length The plastic optical fiber is inserted into the small holes on the plastic base plate, and then the carpenter builds the mold around the plastic base plate covered with optical fibers to complete the preparation of the light-transmitting concrete mold;

[0029] (2) Glass fine aggregate preparation: (each time) weigh 5Kg of waste glass, after simple manual crushing, pour it into the SM-500 cement test ball mill, pour it out after grinding for 3 minutes, sieve, and keep a 4.75mm sieve undersieve;

[0030] (3) Weigh raw materials by weight: water: 135 parts, PO42.5...

Embodiment 3

[0033] A method for preparing glass fine aggregate light-transmitting concrete, comprising the following steps:

[0034] (1) Optical fiber layout and mold preparation: use the microcomputer program to operate the drilling machine, drill holes on the rubber base plate, and form a set pattern composed of countless small holes on the rubber base plate, and then place a circular cross-section plastic with a specific diameter and length The optical fibers are inserted into the small holes on the plastic base plate, and then the carpenter builds the mold around the plastic base plate covered with optical fibers to complete the preparation of the light-transmitting concrete mold;

[0035] (2) Glass fine aggregate preparation: (each time) weigh 5Kg waste glass, after simple manual crushing, pour it into the SM-500 cement test ball mill, pour it out after grinding for 5 minutes, sieve, and keep a 4.75mm sieve undersieve;

[0036] (3) Weigh raw materials by weight: water: 135 parts, PO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com