High-identification-property bituminous pavement material and method for paving same

An asphalt pavement, recognition technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of unsatisfactory lighting effect, poor pavement recognition, low road alignment standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] The particle size of the glass aggregate is 3-5mm, and the particle density is required to be 2.4g / cm 3 , bulk density is 1.3g / cm 3 . The coefficient of thermal expansion is 818×10 -6 cm / °C, the softening point is 718°C.

[0022] The high-visibility asphalt pavement material of this embodiment is laid according to the following steps: 1. Take 81 parts of limestone mineral material, 6 parts of asphalt, 5 parts of limestone mineral powder and 8 parts of glass aggregate according to the weight fraction ratio; 2. Mix the ore Mix aggregate and glass aggregate and heat to 180-190°C, dry mix for 30s, then add asphalt at 155°C-180°C and mix for 90s, then add mineral powder at room temperature and mix for 90s to obtain glass aggregate asphalt mixture; 3. The glass aggregate asphalt mixture is mixed, paved, and rolled to obtain a high-visibility asphalt pavement; step 3 glass aggregate asphalt mixture is mixed by batch mixing; step 3 uses the whole Paving, the paving temperat...

specific Embodiment approach 2

[0024] The particle size of the glass aggregate is 3-5mm, and the particle density is required to be 2.6g / cm 3 , bulk density is 1.4g / cm 3 . The coefficient of thermal expansion is 912×10 -6 cm / °C, the softening point is 738°C.

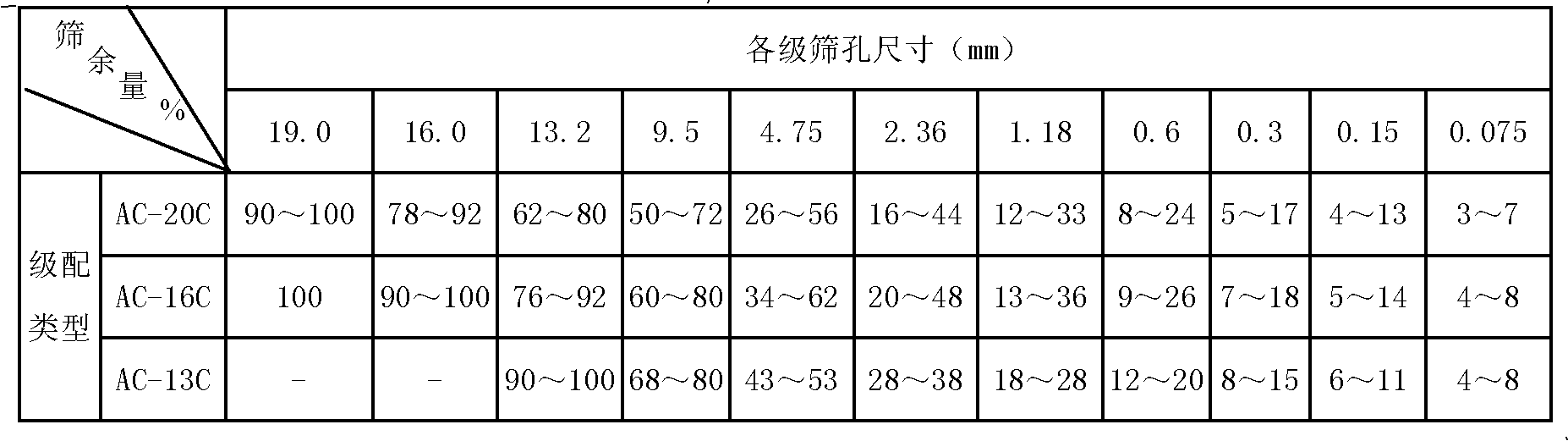

[0025] The difference between this embodiment and specific embodiment 1 is that the high-visibility asphalt pavement material is made of 85 parts of limestone mineral material, 5 parts of asphalt, 4 parts of limestone mineral powder and 6 parts of glass aggregate by weight fraction. The gradation of medium ore materials adopts AC-16C gradation, and other implementation steps are the same as those in Embodiment 1.

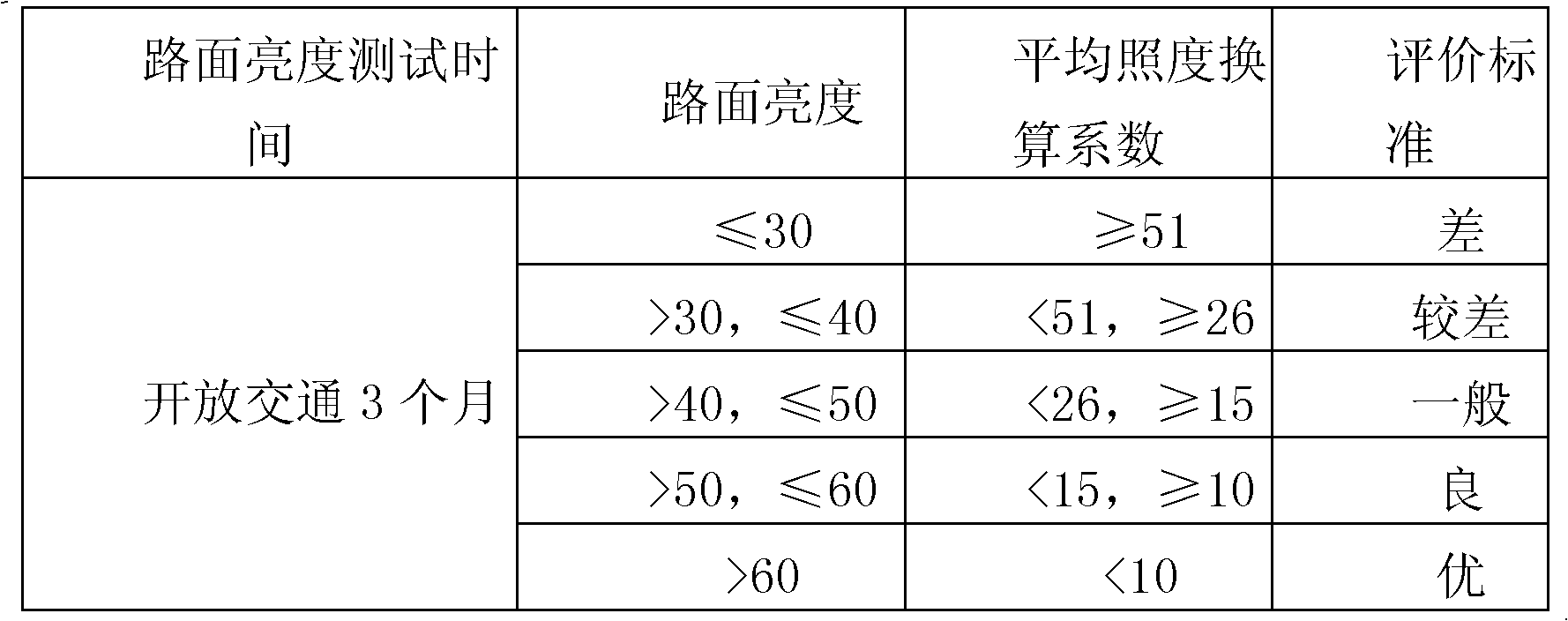

[0026] After the high-visibility asphalt pavement paved in this embodiment is opened to traffic for 3 months, the CR-140 color difference meter is used to test the brightness of the road surface, and at 1000m 2 The road surface was tested at 10 points. The road brightness was 72, 71, 75, 78, 80, 75, 72, 73, 76, and 75. The average value...

specific Embodiment approach 3

[0027] The particle size of the glass aggregate is 3-5mm, and the particle density is required to be 2.4g / cm 3 , bulk density is 1.4g / cm 3 . The coefficient of thermal expansion is 818×10 -6 cm / °C, the softening point is 718°C.

[0028] The difference between this embodiment and the specific embodiment 1 is that the high-visibility asphalt pavement material is made of 82 parts of limestone mineral material, 5.5 parts of asphalt, 5.5 parts of limestone mineral powder and 7 parts of glass aggregate. The gradation of medium ore materials adopts AC-13C gradation, and other implementation steps are the same as those in Embodiment 1.

[0029] After the high-visibility asphalt pavement paved in this embodiment is opened to traffic for 3 months, the CR-140 color difference meter is used to test the brightness of the road surface, and at 1000m 2 Tested at 10 points within the road surface, the road brightness was 74, 76, 76, 75, 79, 76, 78, 75, 77, 75, the average value was 76.1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com