Patents

Literature

47results about How to "Spacing control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Group control system for multi-car elevators and safety control method thereof

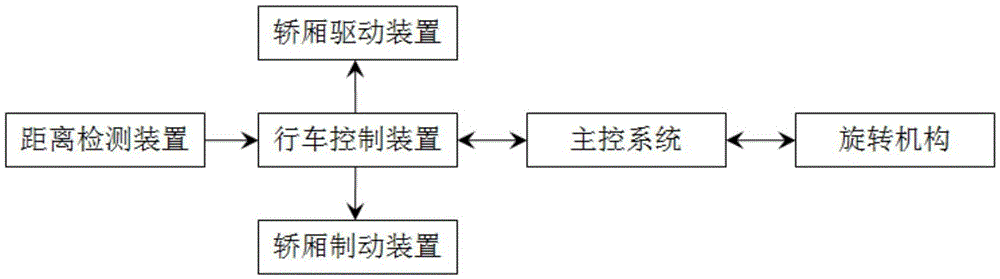

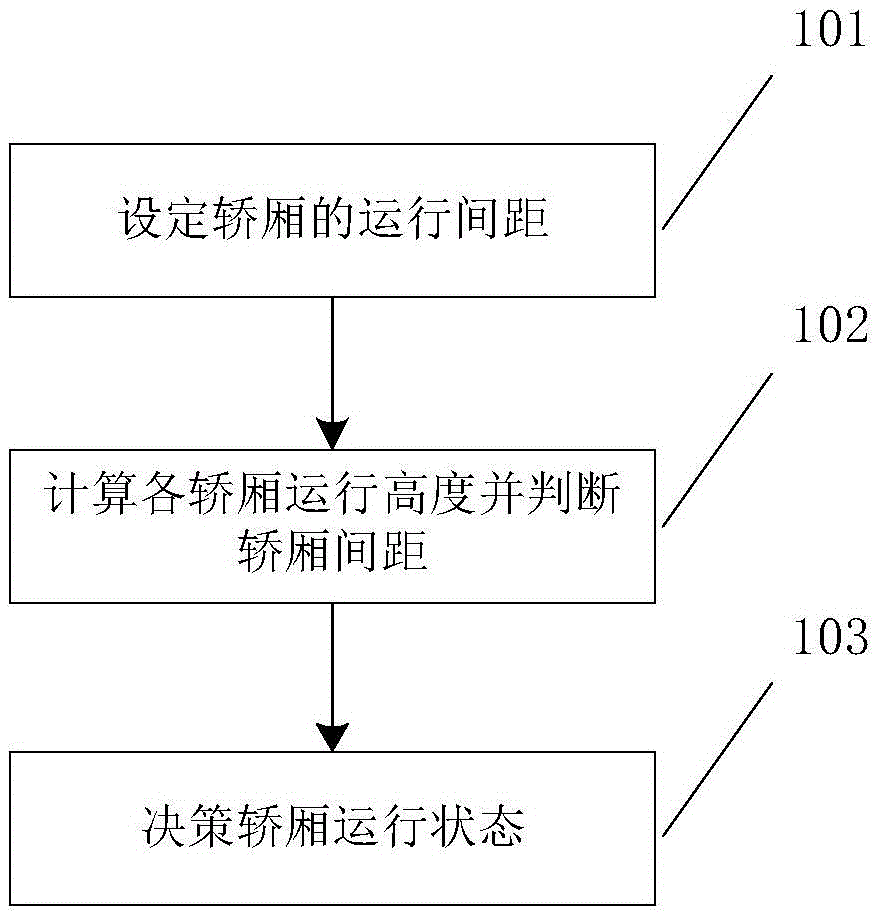

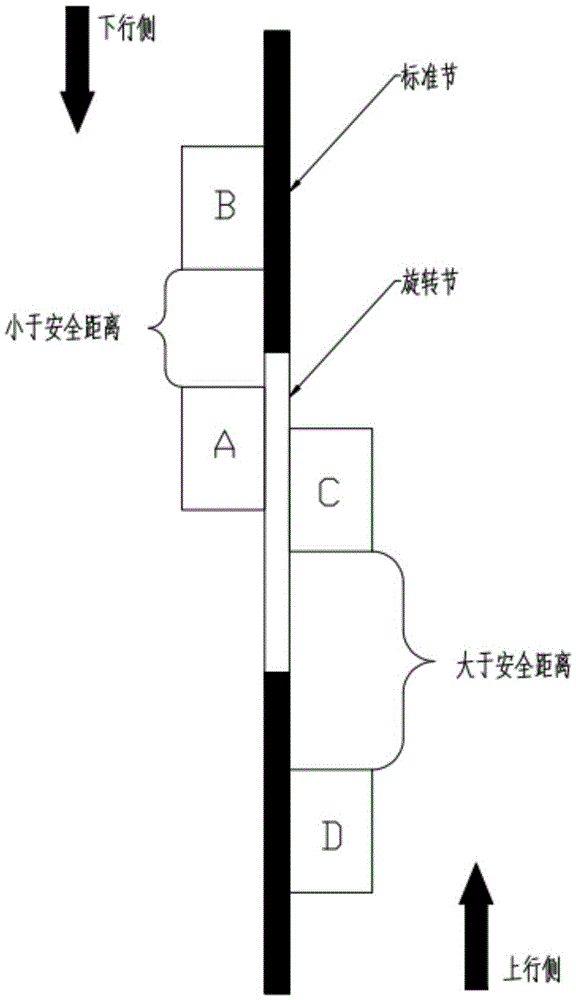

The invention provides a group control system for multi-car elevators and a safety control method thereof. According to the group control system for the multi-car elevators and the safety control method thereof, the safe distance between cars and between the cars and rotating mechanisms can be monitored in real time, the operating state of the cars can be controlled, and the safety can be improved. According to the system, a distance monitoring device tracks and monitors the height of the cars and the distance between the cars, the minimum safe distance and the forced stop distance are set, when the distance between the cars is smaller than the safe distance but greater than the forced stop distance, the cars slow down for operation, when the distance between the cars is smaller than the forced stop distance, the cars stop operating, the distance between the cars can be effectively controlled, the buffering effect can be realized, and the cars can be prevented from suddenly stopping. A height detection coder and distance measuring instruments are adopted for monitoring the distance between the cars, and therefore the safety factor is increased, collision between the cars is effectively prevented, and the robustness of the system is improved.

Owner:WISDRI WUHAN AUTOMATION

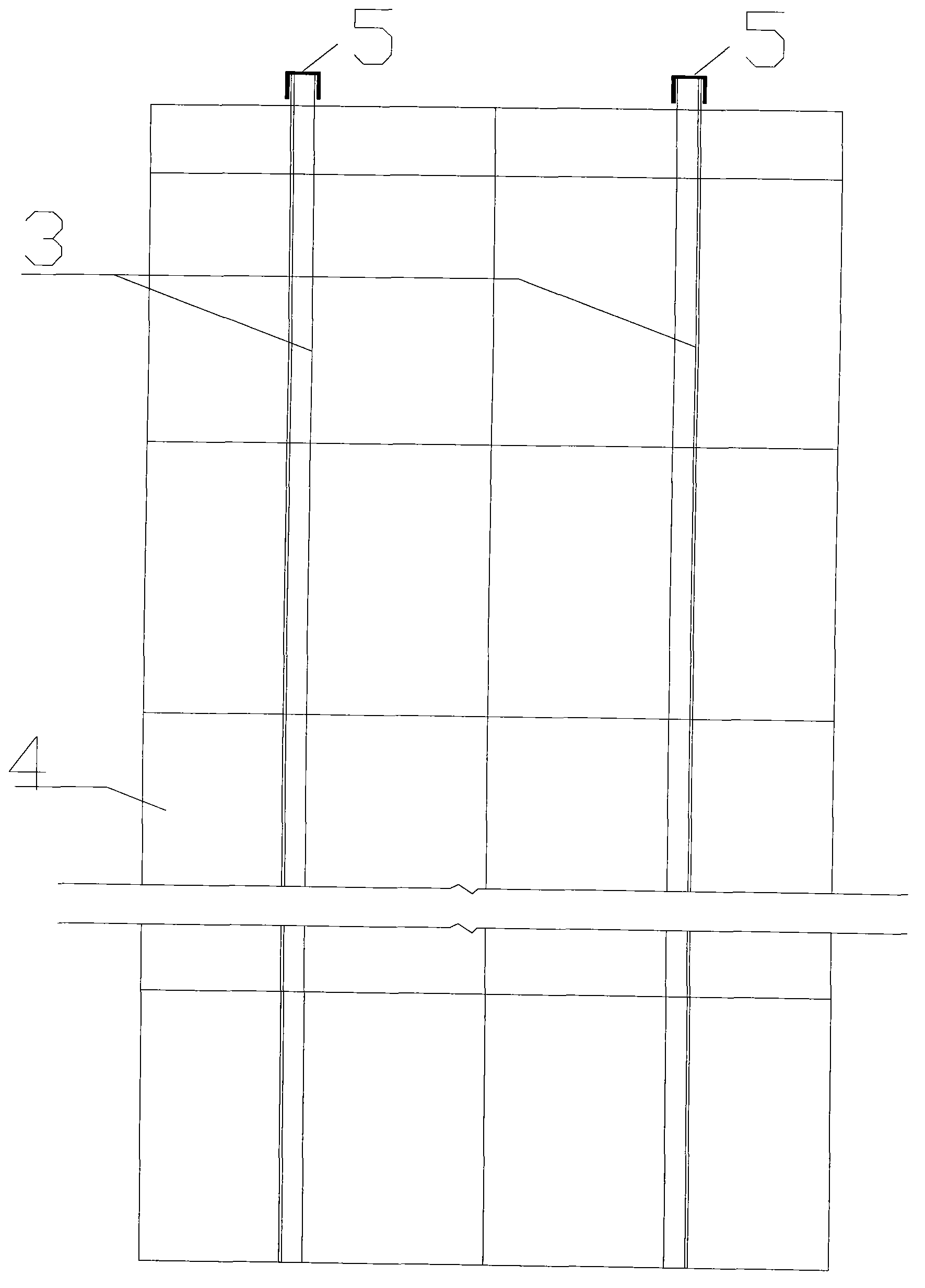

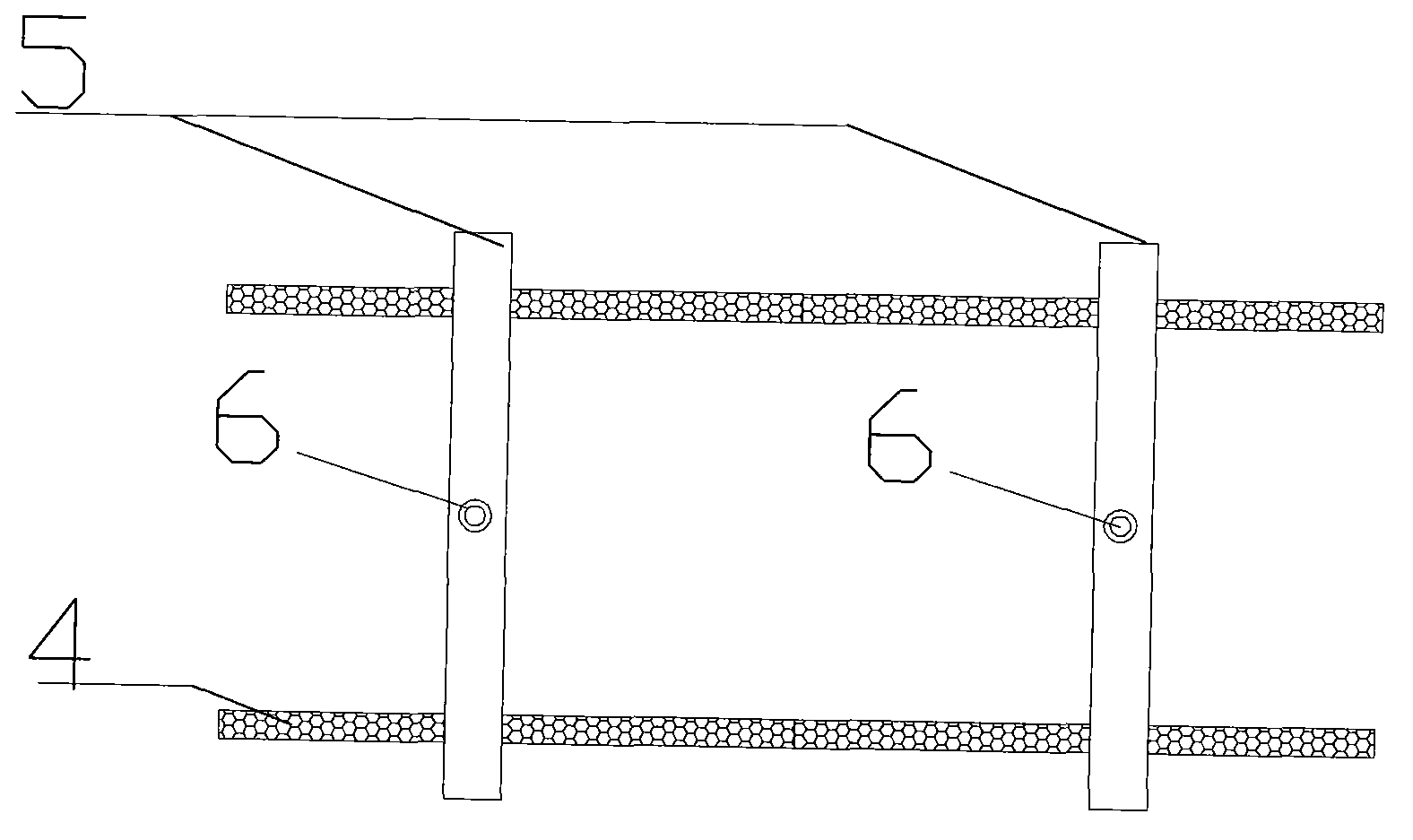

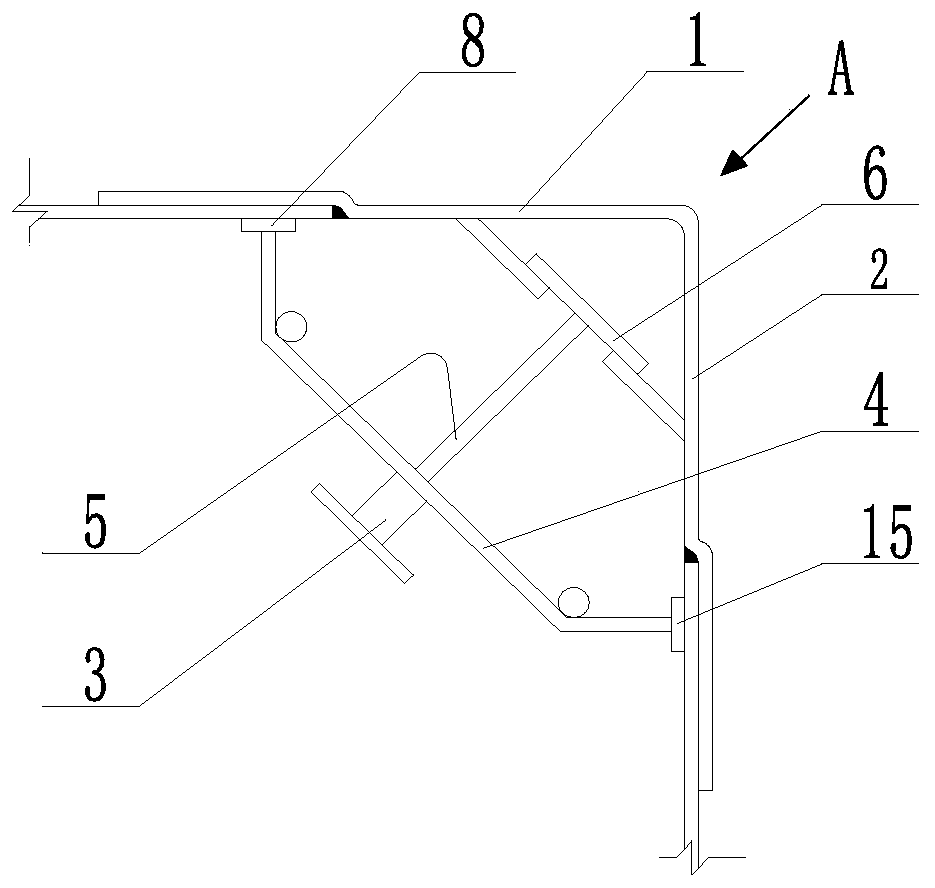

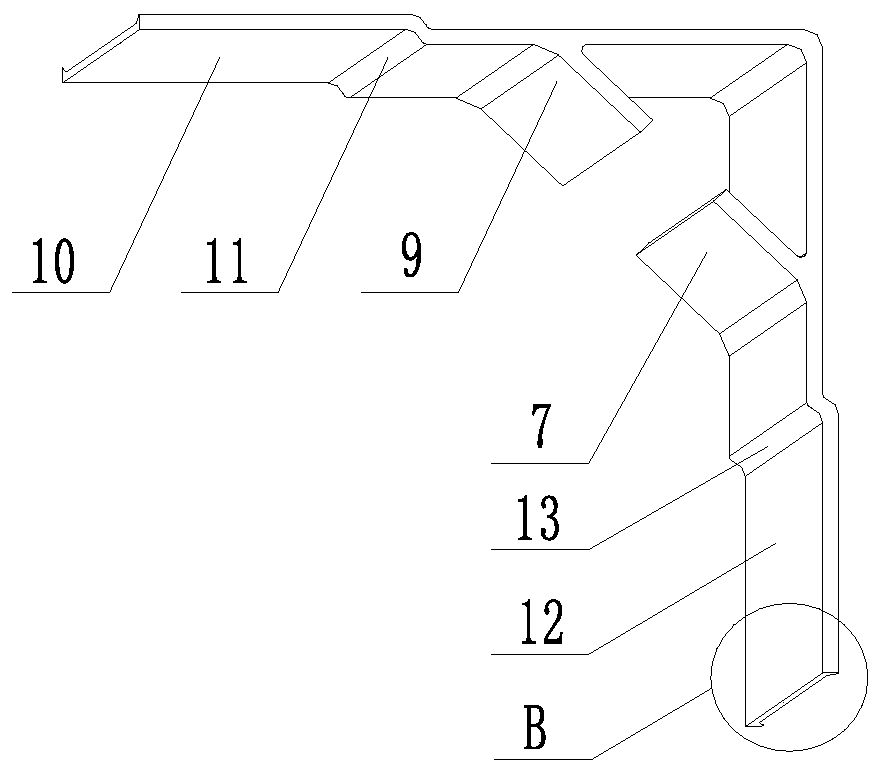

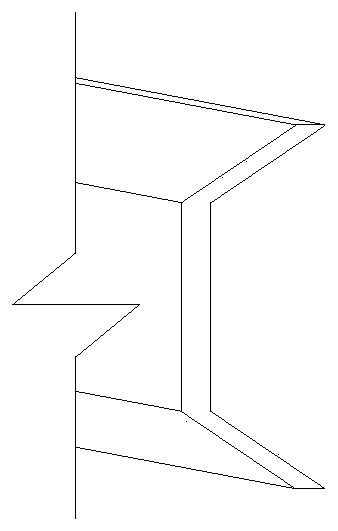

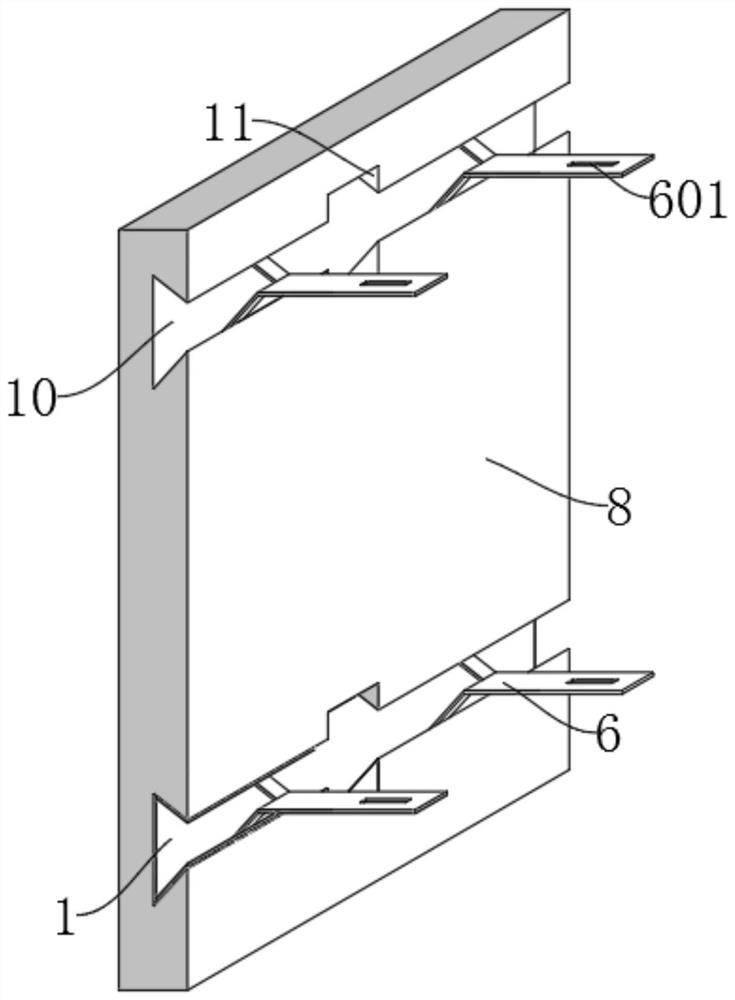

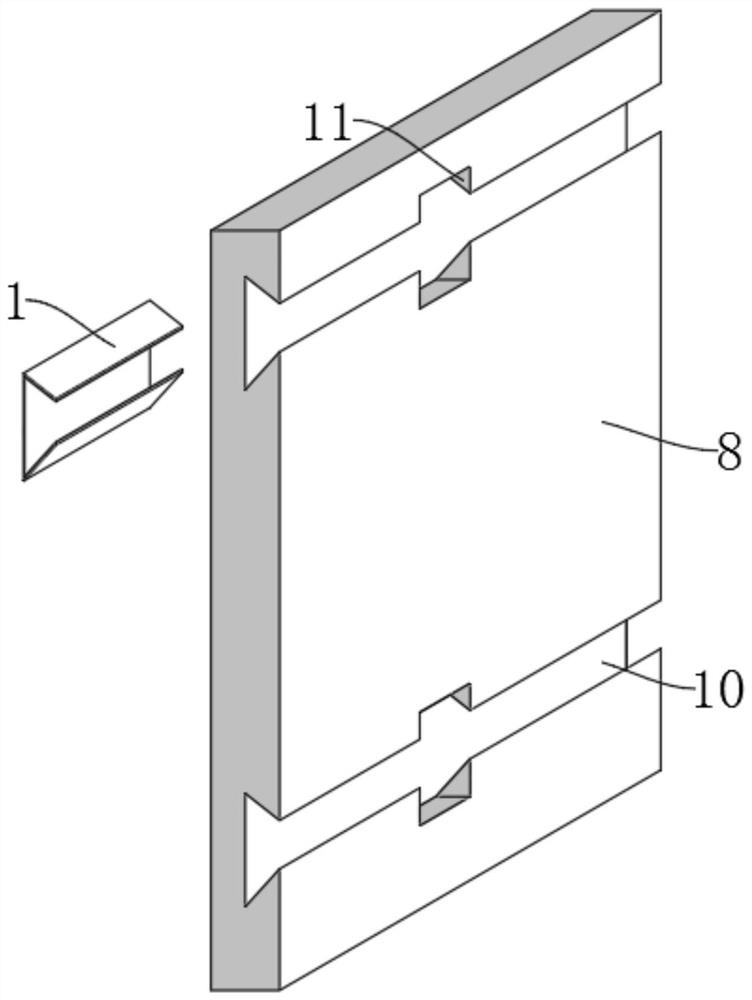

Double concrete wall plate scissor type keel supporting template system

InactiveCN103541544ASolve the whereabouts problemSpacing controlAuxillary members of forms/shuttering/falseworksSupporting systemKeel

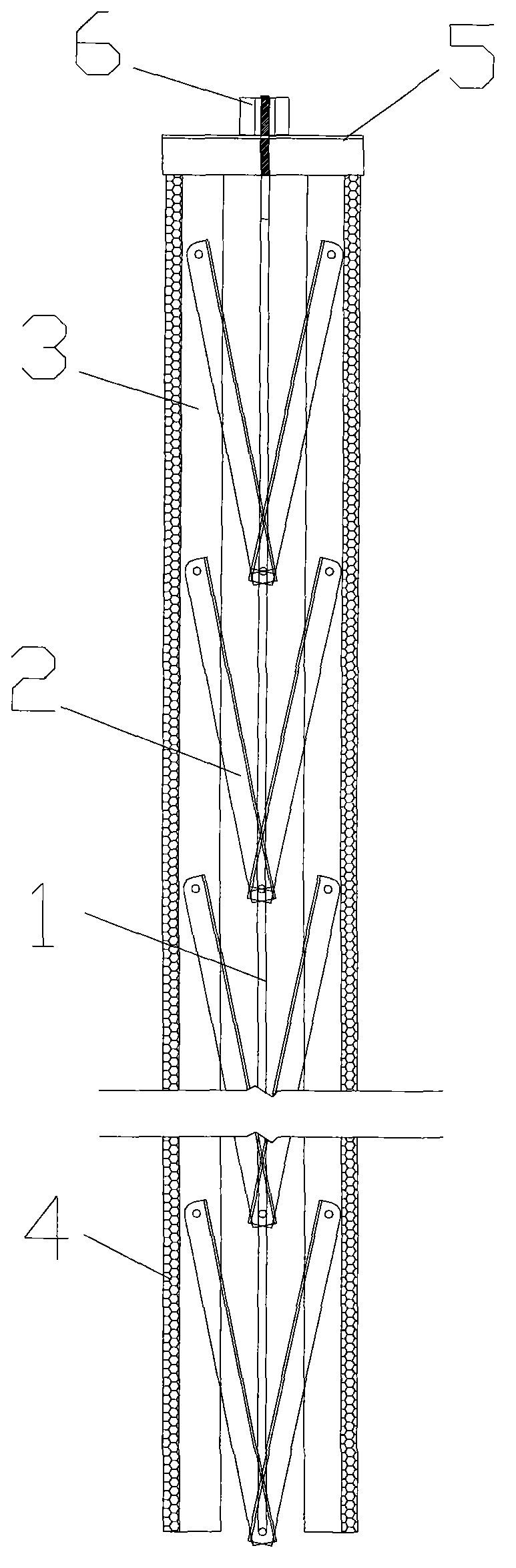

The invention discloses a double concrete wall plate scissor type keel supporting template system which comprises a central pull rod, hinge rods, main keels, template panels, a fixing baffle and fastening screws, a pair of main keels is hinged to a connecting rod system composed of the hinge rods and the central pull rod. The template panels are fixed on the main keels. A plurality of pairs of hinge rods are arranged on the central pull rod. The fixed baffle is arranged on the upper portion of the central pull rod. The fastening screws are arranged at the upper end of the central pull rod. The pair of main keels is located on the two sides of the central pull rod. Hinges are connected to the hinge rods. Two keel systems are connected through the template panels to form the scissor type supporting template system. The double concrete wall plate scissor type keel supporting template system solves the problems that two adjacent concrete wall bodies can not be constructed at the same time, supporting keels and templates between the two walls are hard to detach, and the project progress is influenced. The supporting system utilizes the screws at the upper end of the central pull rod of the rotating system, the interval between two wall plate templates, the two wall templates and the supporting system are made to form an organic integrity.

Owner:谢月实 +1

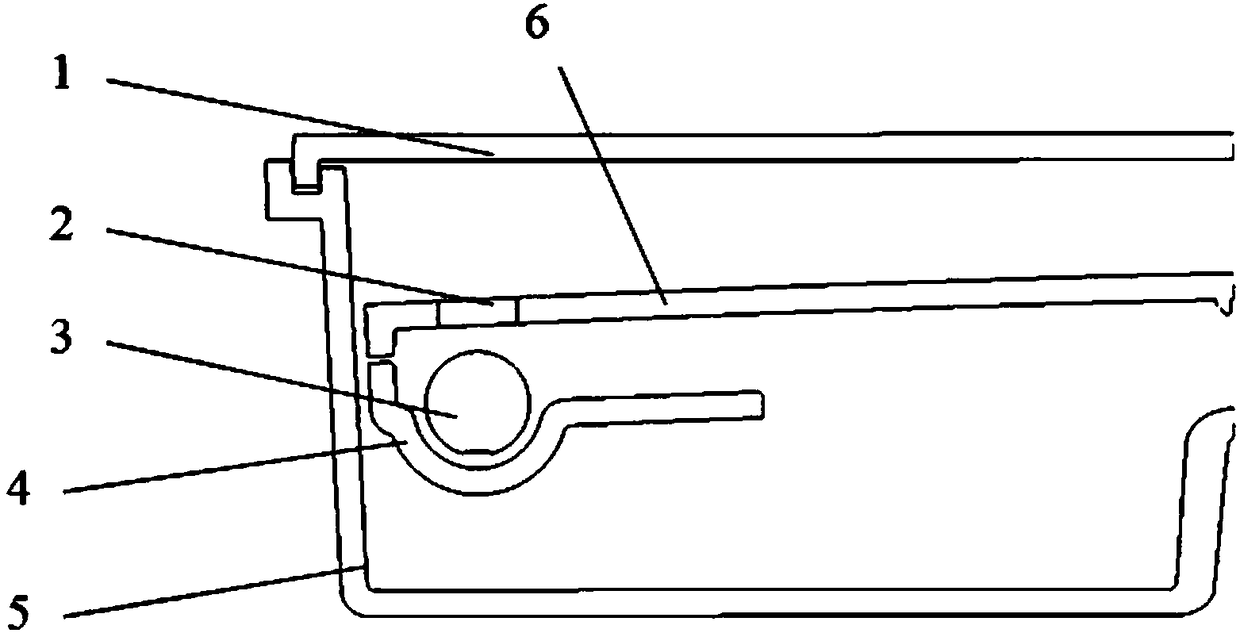

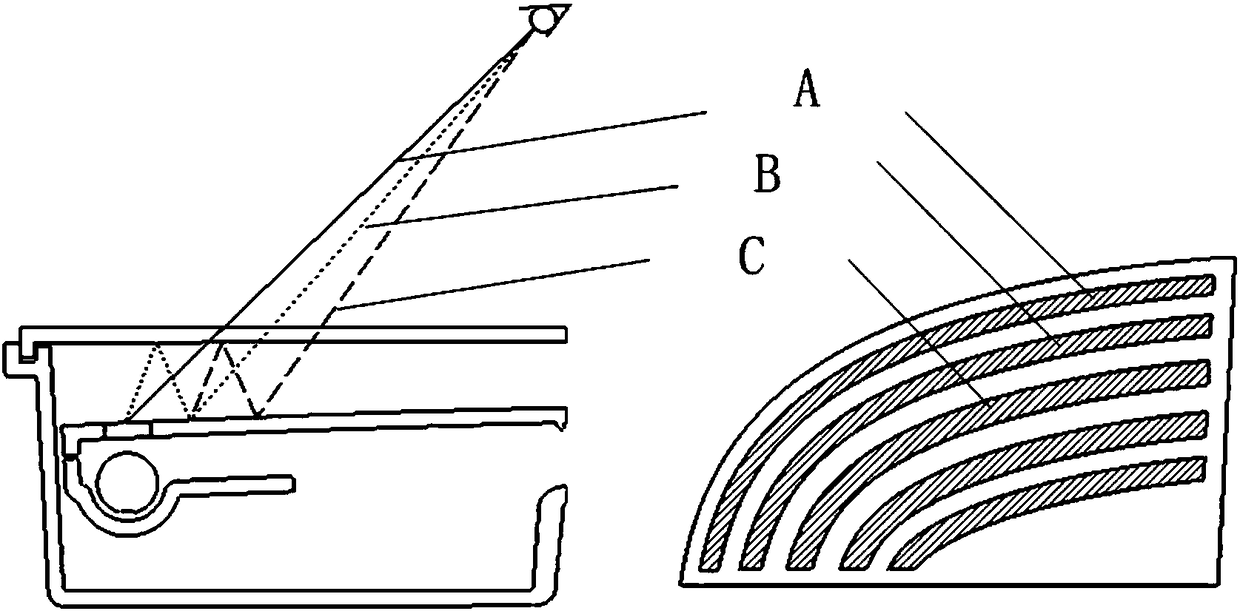

Automobile tail lamp with 3D depth visual effect

PendingCN108518647ATranslucentSpacing controlOptical signallingRoad vehiclesVisual perceptionLight-emitting diode

The invention relates to an automobile tail lamp with the 3D depth visual effect. The tail lamp is provided with a reflector, a discrete type inner lens is inlaid in the reflector, and the front sidesurface of the reflector is a reflecting surface; a semi-transparent semi-reflector is arranged in front of the reflector, and a gap is reserved between the reflector and the semi-transparent semi-reflector; and a light emitting body is arranged behind the reflector, the discrete type inner lens is opposite to the light-emitting surface of the light-emitting body in a front-back mode, and the occupied area of the discrete type inner lens corresponds to the extending range of the light emitting body. According to the tail lamp, the limitation of the depth of a lamp cavity of an existing vehiclelamp is broken through so that the tail lamp realization type that a user can experience the depth sense in front of the tail lamp and the 3D effect is achieved is provided, the three-dimensional effect is high, the manufacturing cost is low, and the tail lamp has strong competitiveness on the cost and the appearance effect.

Owner:HASCO VISION TECHNOLOGY CO LTD

Perforating equipment for carton

InactiveCN110843247ASpacing controlMeet the needs of practical operationBox making operationsPaper-makingGear wheelCarton

The invention discloses perforating equipment for a carton. The perforating equipment comprises a casing; a driving gear is arranged in the middle of the back surface of the inner surface of the casing; a handle is arranged at one end, located on the back surface of the casing, of a connecting rotating shaft on the driving gear; fixing sliding seats are arranged in the positions, symmetric about the central axis of the casing, of the back surface of the inner surface of the casing; perforating drills are rotationally connected to the inner surfaces of the fixing sliding seats through sliding blocks and connecting shafts; the perforating drills can be dismounted; and the outer surfaces of the connecting shafts are in meshing transmission with the driving gear through driven gears. Accordingto the perforating equipment, the casing is closely attached to a carton body, then the handle is rotated to drive the driving gear to rotate to drive the driven gears to rotate to drive the connecting shafts to rotate, the connecting shafts rotate to drive the perforating drills to rotate to perforate the carton body conveniently and quickly, and all that is required is to dismount the perforating drills when a single hole is required to be drilled.

Owner:灵璧县旭升包装材料有限公司

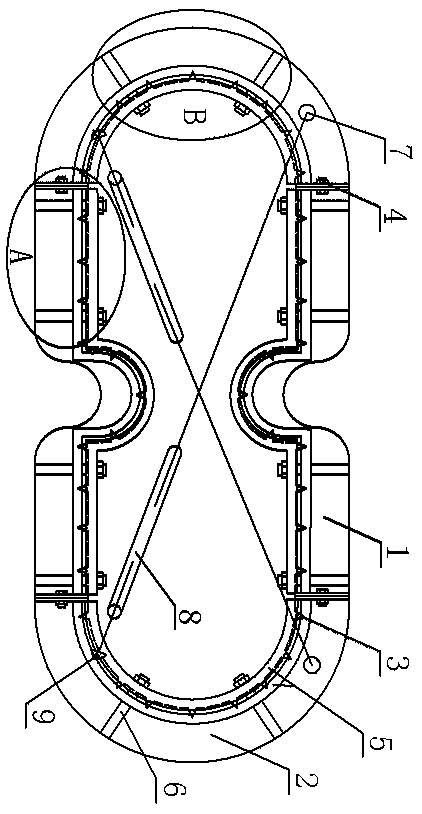

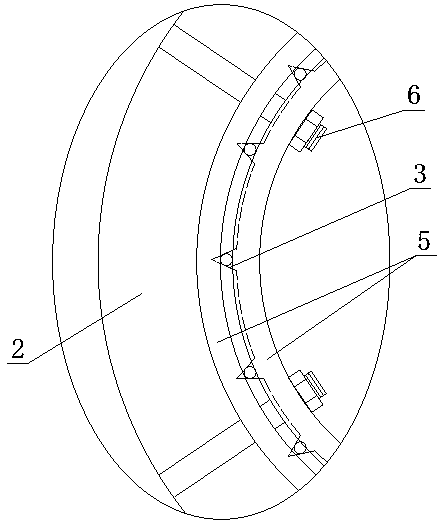

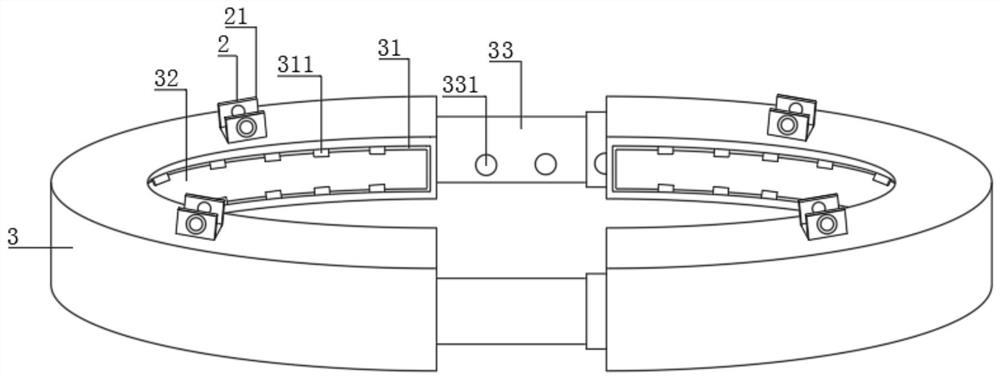

Accurate control device for high-speed railway bridge pier column steel bar protective layer

PendingCN110205941AFix bugsSignificantly spacedBridge structural detailsBridge erection/assemblyDesign standardSelf locking

The invention discloses an accurate control device for a high-speed railway bridge pier column steel bar protective layer. According to the accurate control device, two straight skeletons are connected with two arched skeletons to form an arc-shaped limiting skeleton, and an inner straight fixing clamping plate and an outer straight fixing clamping plate and an inner arc-shaped fixing clamping plate and an outer arc-shaped clamping plate are arranged on the straight skeletons and arc-shaped skeletons correspondingly; the middle parts of the straight skeletons bend inwards correspondingly to reserve drainage grooves, and a V-shaped or U-shaped limiting groove is formed in the inner side of the limiting skeleton, and it is ensured that after the limiting skeleton is connected as a whole, anouter bridge pier column pre-embedded steel bar is enabled to be completely clamped in the limiting groove of the limiting skeleton to achieve an self-locking effect; and the pre-embedded steel bar iscorrected vertically by a steel wire rope, turnbuckles and shackles which are fixed on the limiting skeleton, so that the verticality of pre-embedded steel bars fully meets a design standard, and itis ensured that the thickness error of the concrete protective layer reaches -3, +5 mm, and the spacing error of the steel bars reaches -3, +3 mm, and the accurate control device for the high-speed railway bridge pier column steel bar protective layer is ideal.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

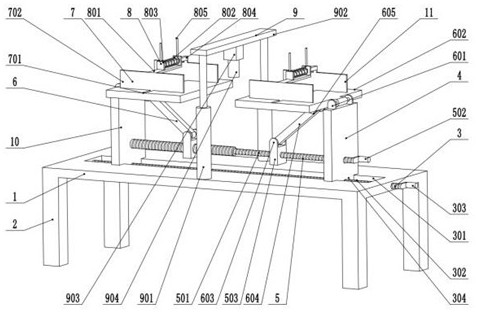

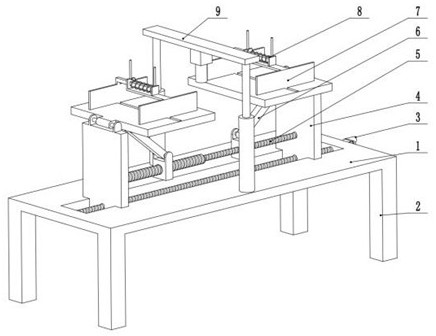

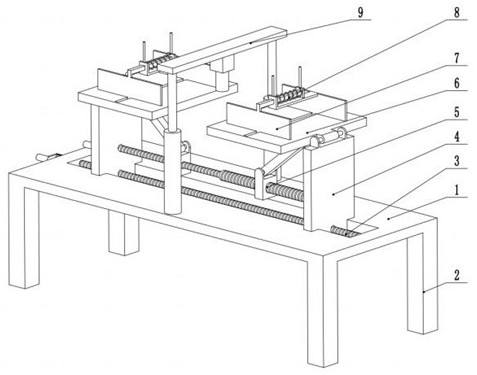

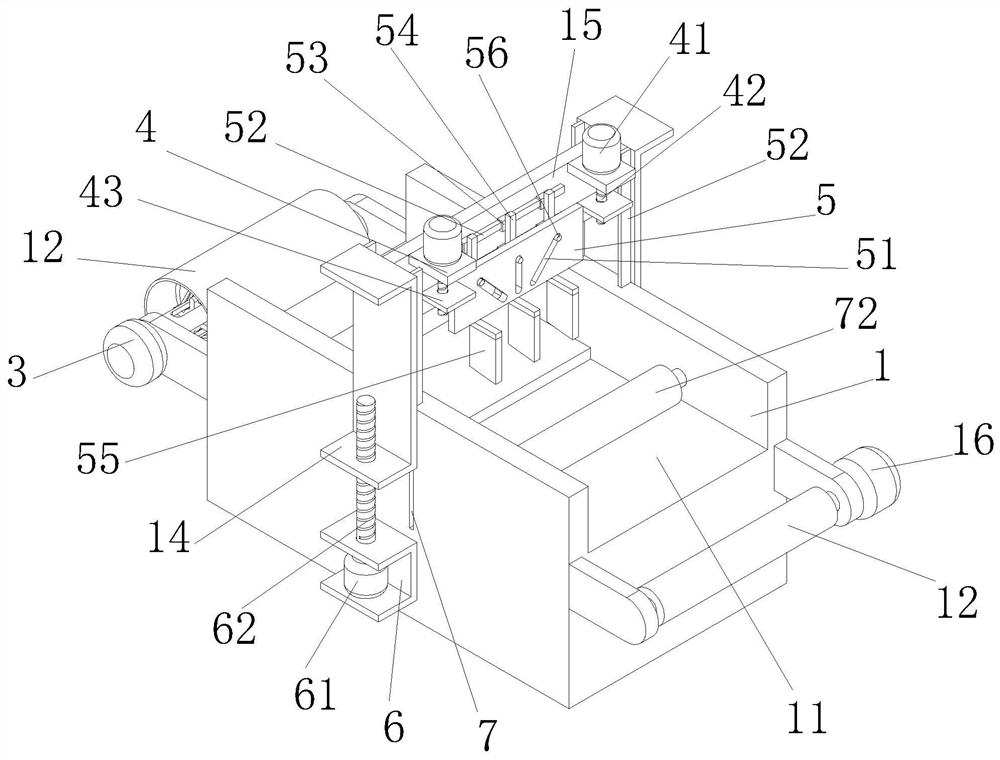

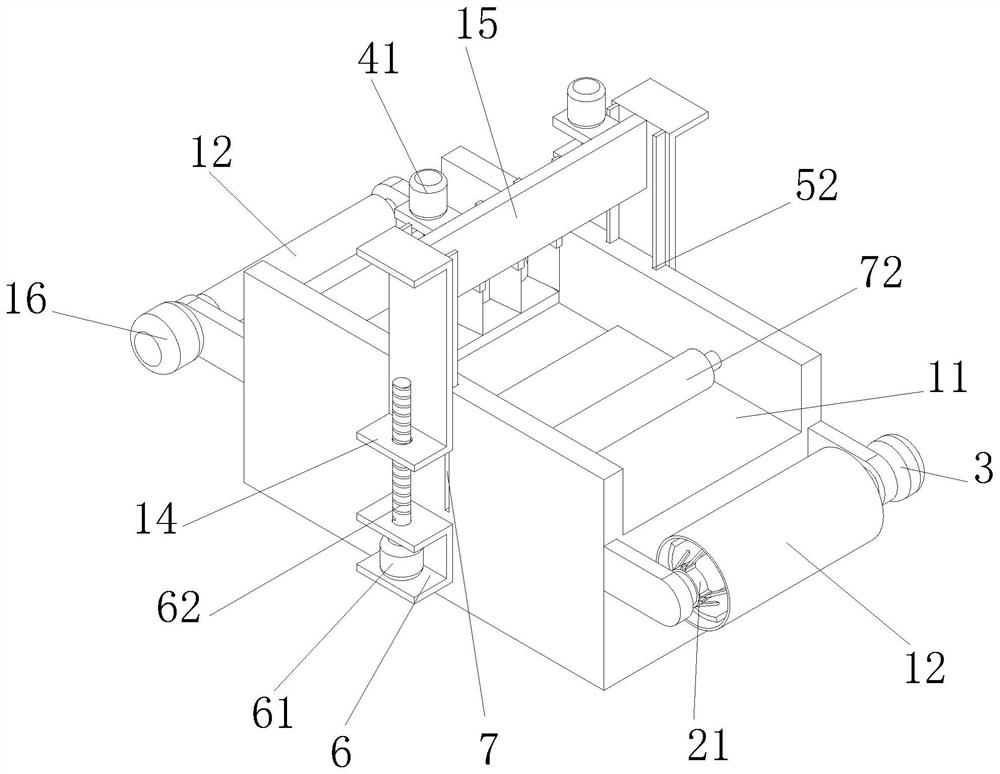

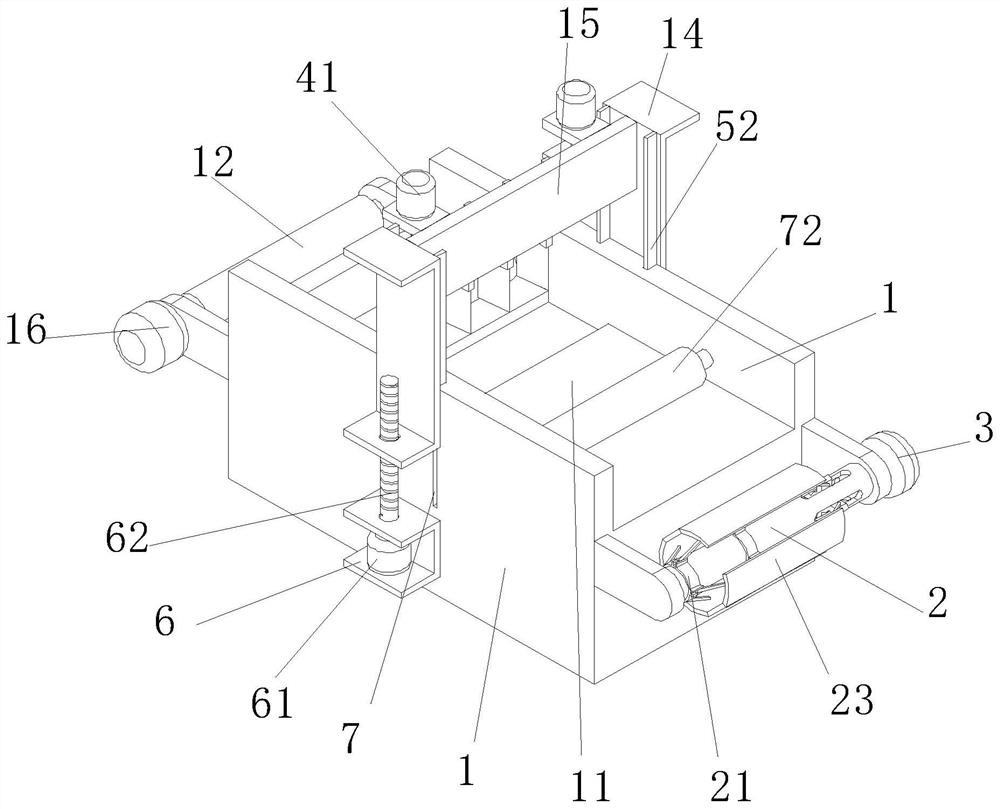

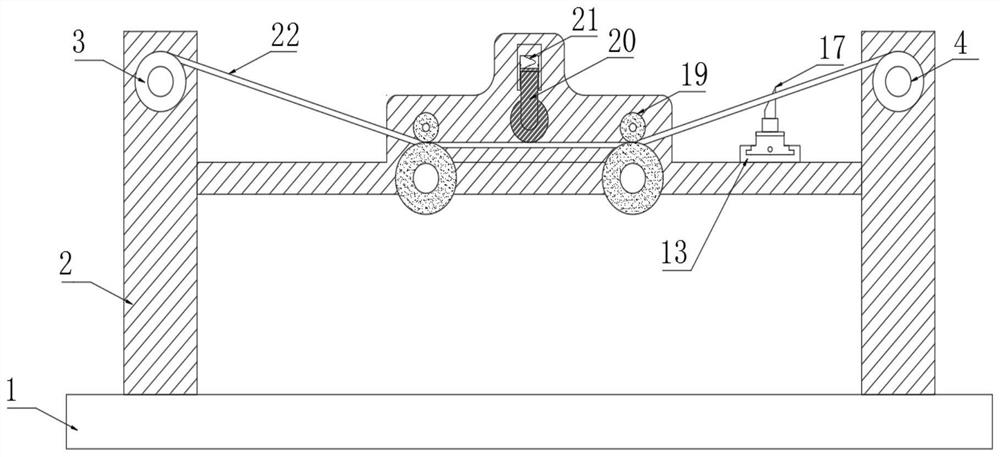

Strength testing equipment for mechanical forming material

InactiveCN113281188ASpacing controlIncrease the efficiency of strength testingMaterial strength using tensile/compressive forcesUltimate tensile strengthMechanical engineering

The invention discloses strength testing equipment for a mechanical forming material, and relates to the technical field of material strength testing, the strength testing equipment comprises a mounting seat and supporting legs fixed at the bottom of the mounting seat; a placement plate assembly is arranged on the mounting seat, the placement plate assembly comprises a spacing adjusting mechanism, a mounting plate, an adjusting mechanism and a placement plate mechanism, the mounting plate is fixed on the spacing adjusting mechanism, the adjusting mechanism is mounted on the mounting plate, and the placement plate mechanism is arranged on the mounting plate and the adjusting mechanism; a clamping assembly is arranged on the placing plate mechanism and comprises a clamping plate mechanism and a pressing handle mechanism; according to the device, the mounting plates can be driven by arranging the distance adjusting mechanism, the distance between the mounting plates can be controlled, the device is suitable for strength testing of workpieces of different sizes, the angle of the placing plate mechanism can be driven to be changed by arranging the adjusting mechanism, and the efficiency of strength testing of the workpieces is improved; and meanwhile, the functions of the equipment are enriched.

Owner:潍坊市工程技师学院

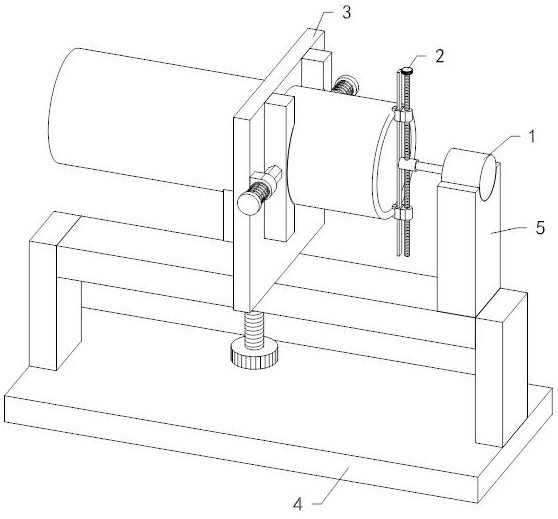

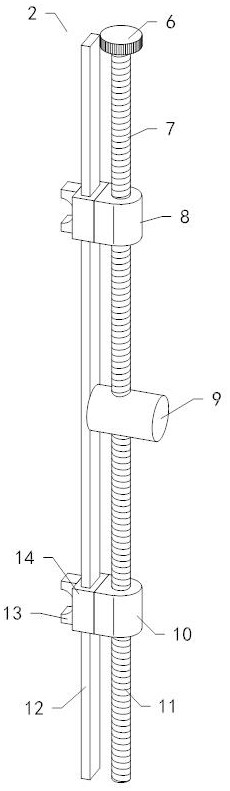

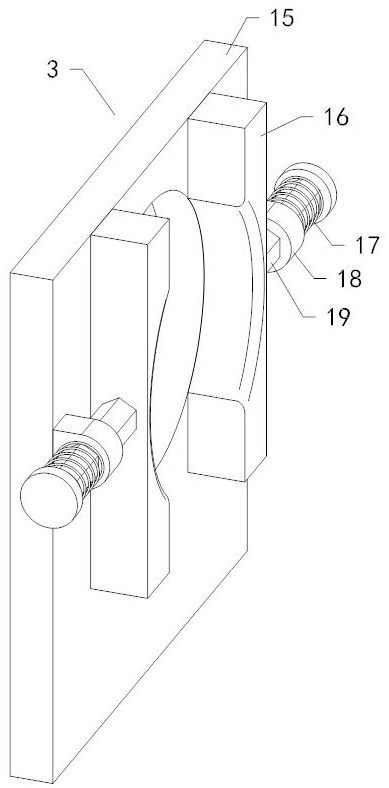

High-corrosion-resistance super duplex stainless steel pipe machining device and machining process thereof

InactiveCN114178924AConvenient grinding workSpacing controlEdge grinding machinesGrinding work supportsElectric machineSS - Stainless steel

The machining device comprises a motor, a polishing rod, a clamp, a supporting seat and a first fixing frame, the lower end of the clamp is fixedly connected to the upper end of the supporting seat, and the side end of the polishing rod is fixedly connected to the outer end of a rotor of the motor; the lower end of the motor is fixedly connected to the upper end of the first fixing frame, the lower end of the first fixing frame is fixedly connected to the upper end of the supporting seat, the polishing rod comprises a first threaded rod, a first nut, a rotating block, a second nut, a second threaded rod, a guide rod, a polishing block and a sliding sleeve, and the thread directions of the first threaded rod and the second threaded rod are opposite. The lower end of the first threaded rod is fixedly connected to the upper end of the second threaded rod. The invention relates to a high-corrosion-resistance super duplex stainless steel pipe processing device and a processing technology thereof, which can be used for conveniently polishing a notch of a steel pipe and better meeting the use requirements.

Owner:JIANGYIN DONGHAO STAINLESS STEEL TUBE CO LTD

LED light supplementing device for potted plants

ActiveCN113228980ATo achieve the connection effectEasy to disassembleSaving energy measuresHorticulture methodsMechanical engineeringMaterials science

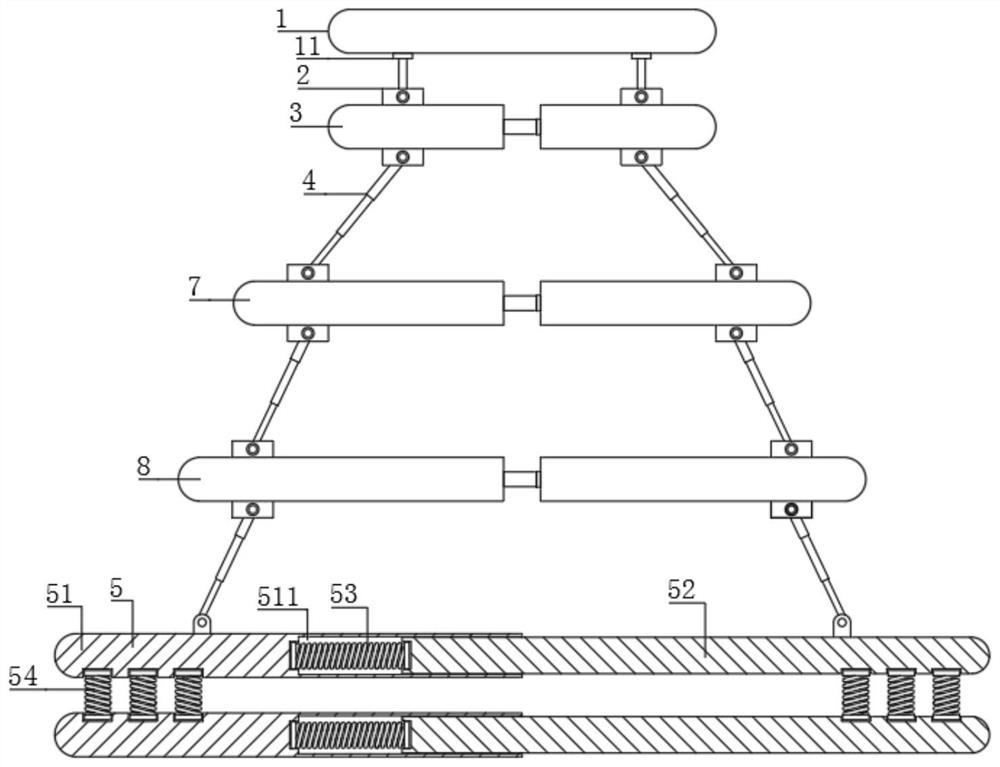

The invention belongs to the technical field of potted plant light supplement, in particular to an LED light supplement device for potted plants. According to the technical scheme, the device comprises a disc type LED light supplement lamp; the bottom end of the disc type LED light supplement lamp is connected with connecting devices; the device further comprises a lamp panel clamp arranged between the connecting devices, and fixing bases arranged at the bottom end of the lamp panel clamp; the bottom end of the lamp panel clamp is connected with a first lamp panel clamp through the connecting devices and a connecting rod; the bottom end of the first lamp panel clamp is connected with a second lamp panel clamp through the connecting devices and the connecting rod; a clamped object is connected between the fixing bases; a clamping groove is formed in the lamp panel clamp; and an LED light supplementing lamp is clamped in the clamping groove. The LED light supplement device for the potted plants has the beneficial effects that the number of lamp panel clamps can be increased or decreased according to requirements, installation and replacement are convenient, the flexibility is high, and the effect of guaranteeing uniform light supplementing is achieved.

Owner:深圳市西地科技有限公司

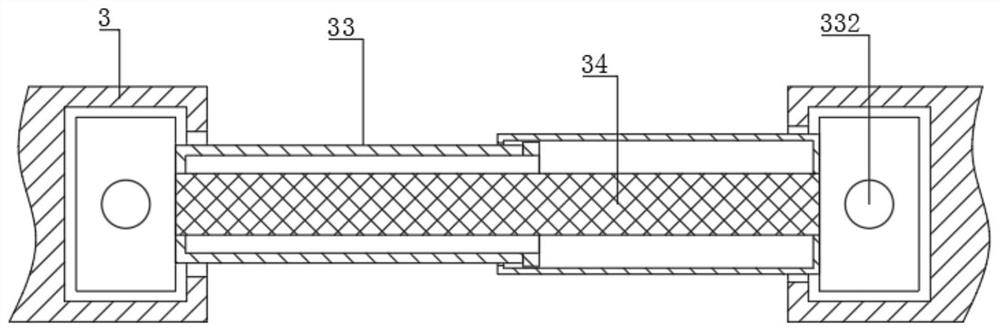

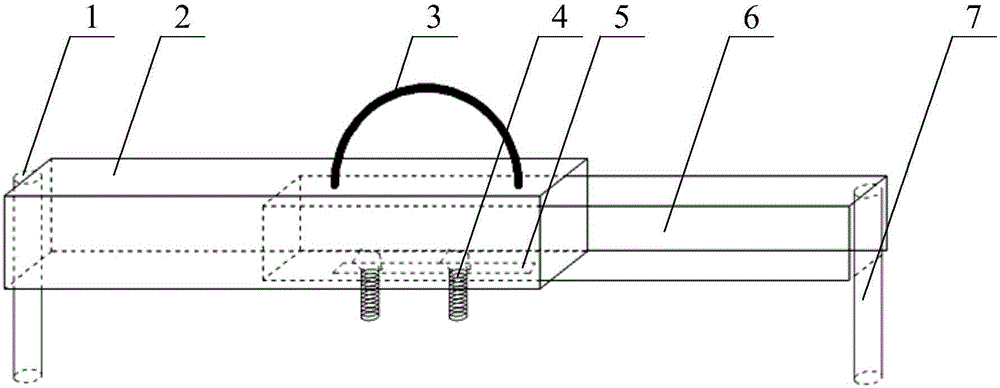

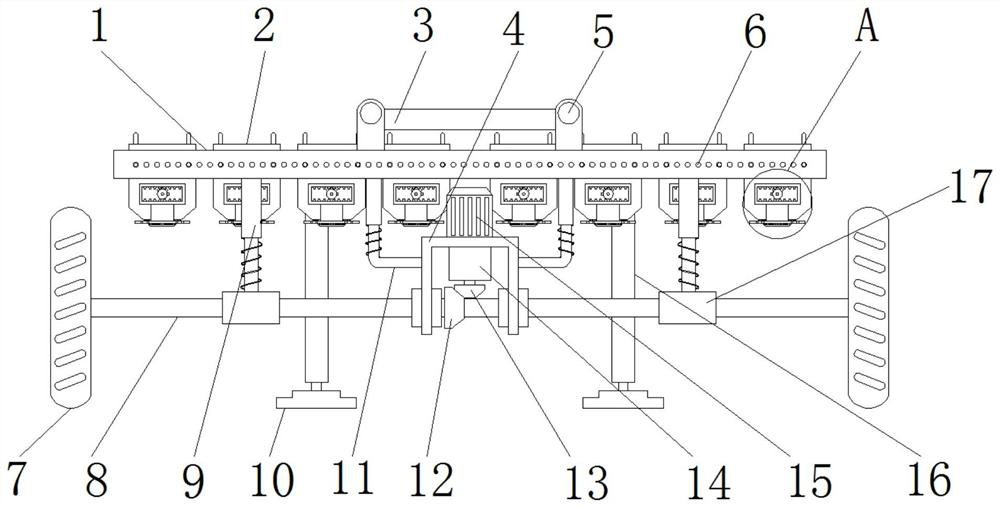

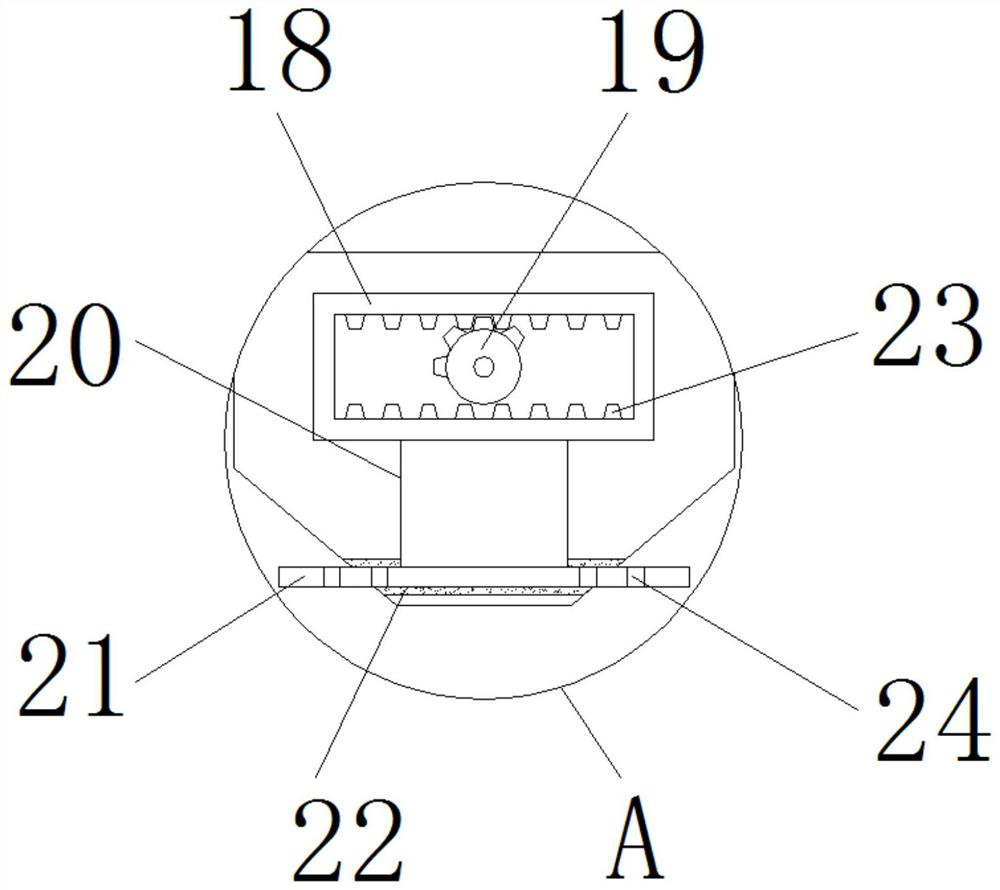

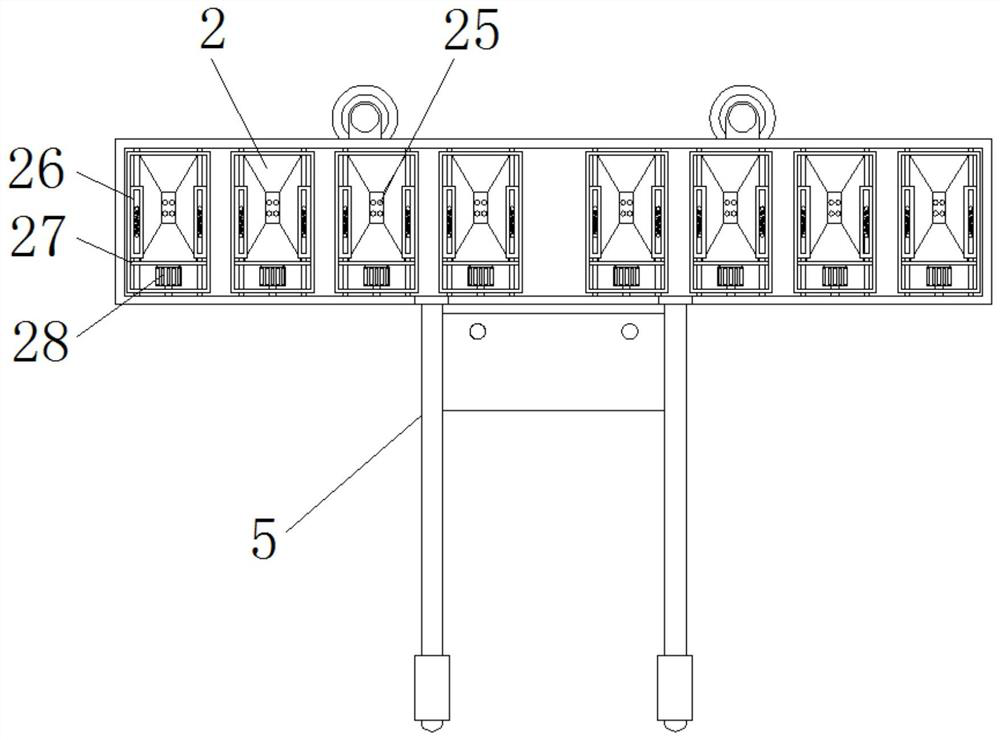

Wheat and corn precision fertilization equipment with wide application range and method thereof

ActiveCN109328581AEasy to assemble and disassembleWide range of applicationsFertiliser distributersFertilising methodsFertilizerTape measure

The invention discloses wheat and corn precision fertilization equipment with a wide application range and a method thereof. The precision fertilization equipment comprises a rectangular frame and a granular fertilizer storage box. The method comprises the following steps: performing first plowing on a land before fertilization; measuring the spacing between two adjacent sowing positions through asteel tap; squeezing two symmetrically arranged L-shaped poke rods and compressing a spring 3 to ensure that one end of each L-shaped poke rod moves out of a clamping groove; and carrying out operations in sequence to disassemble all granular fertilizer storage boxes. By measuring the spacing between adjacent seedlings, and the spacing between two granular fertilizer storage boxes correspondinglyarranged in a rectangular frame, the spacing between adjacent granular fertilizer storage boxes is convenient to adjust, the application range is enlarged, the limitation is small, the spacing between adjacent granular fertilizer storage boxes can be controlled to correspond to adjacent sowing places, the fertilizing precision is improved, the operation process is time-saving and labor-saving, shaking is generated through buffering of a shock absorber 1 and a shock absorber 2, and convenience is provided for a handheld operation process.

Owner:董保成

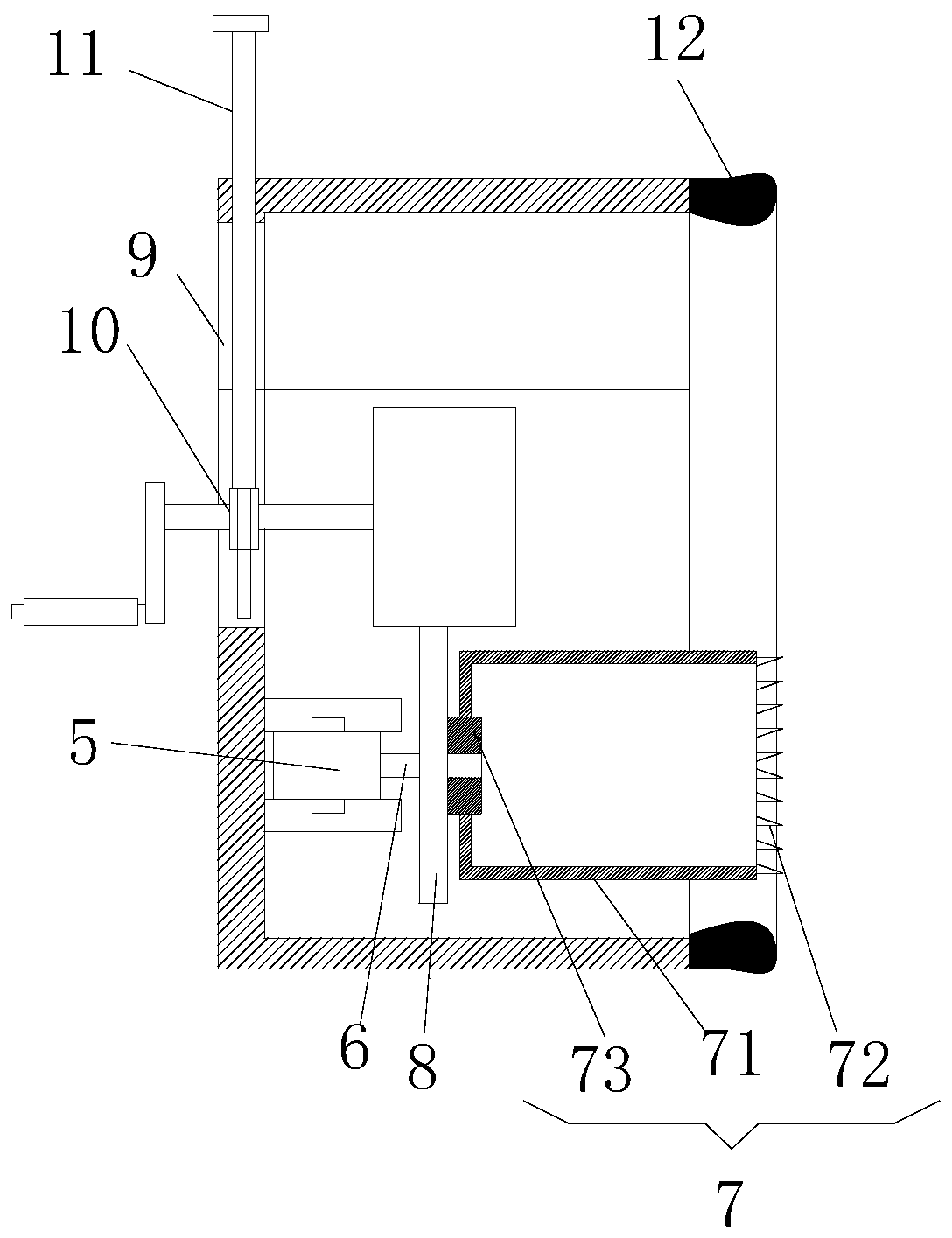

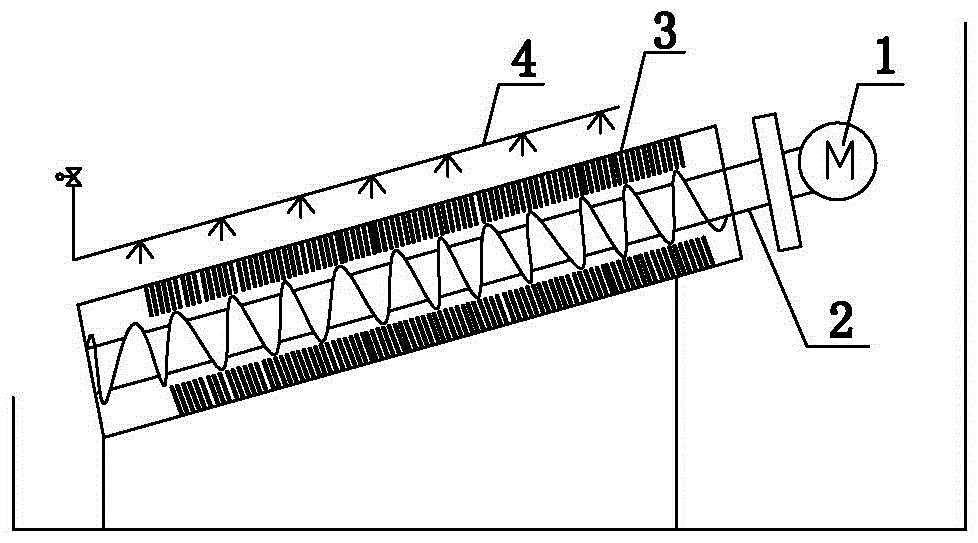

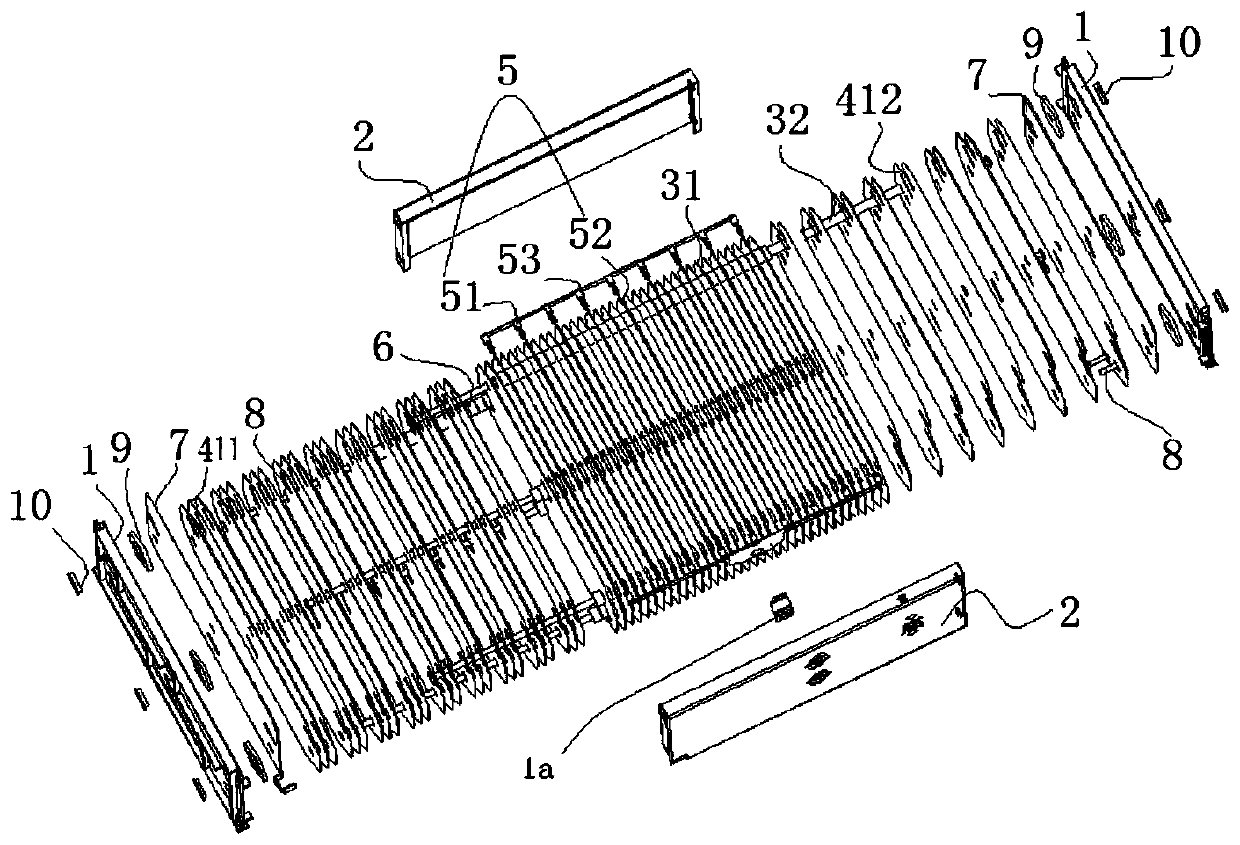

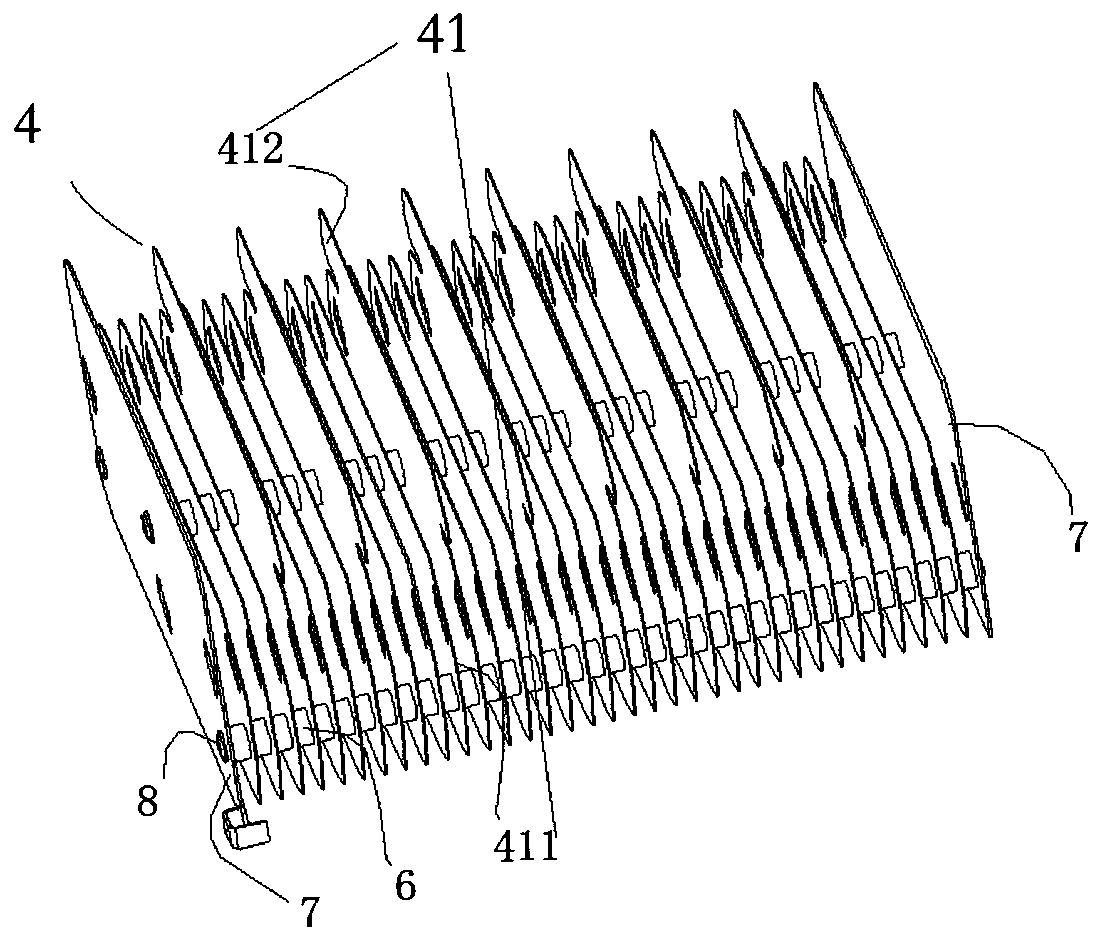

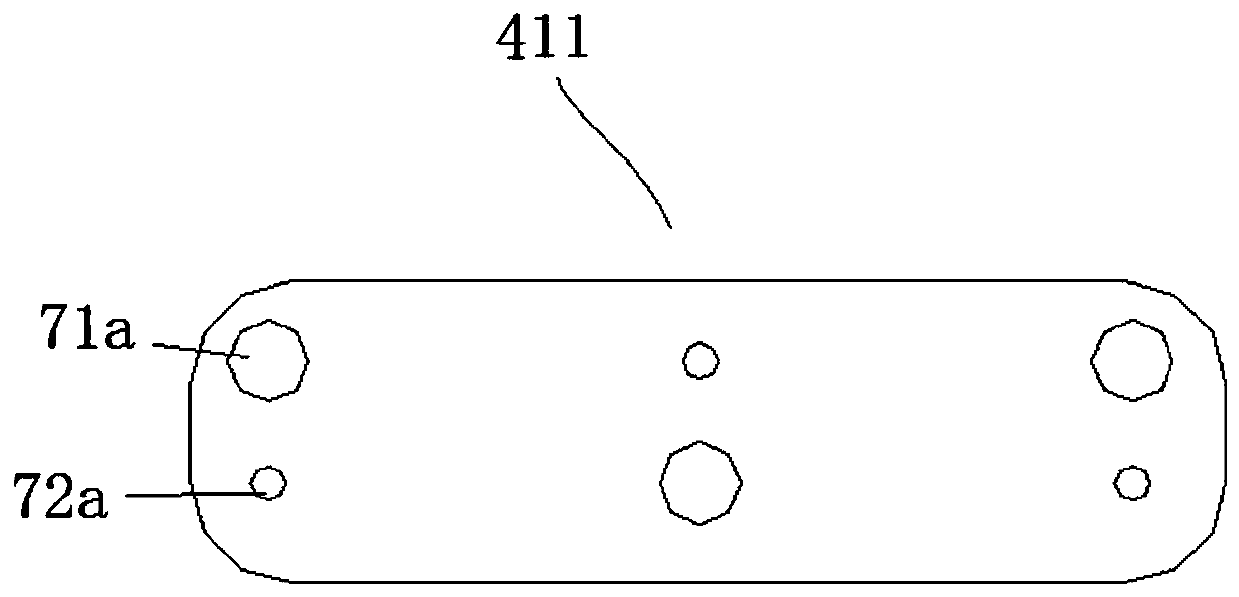

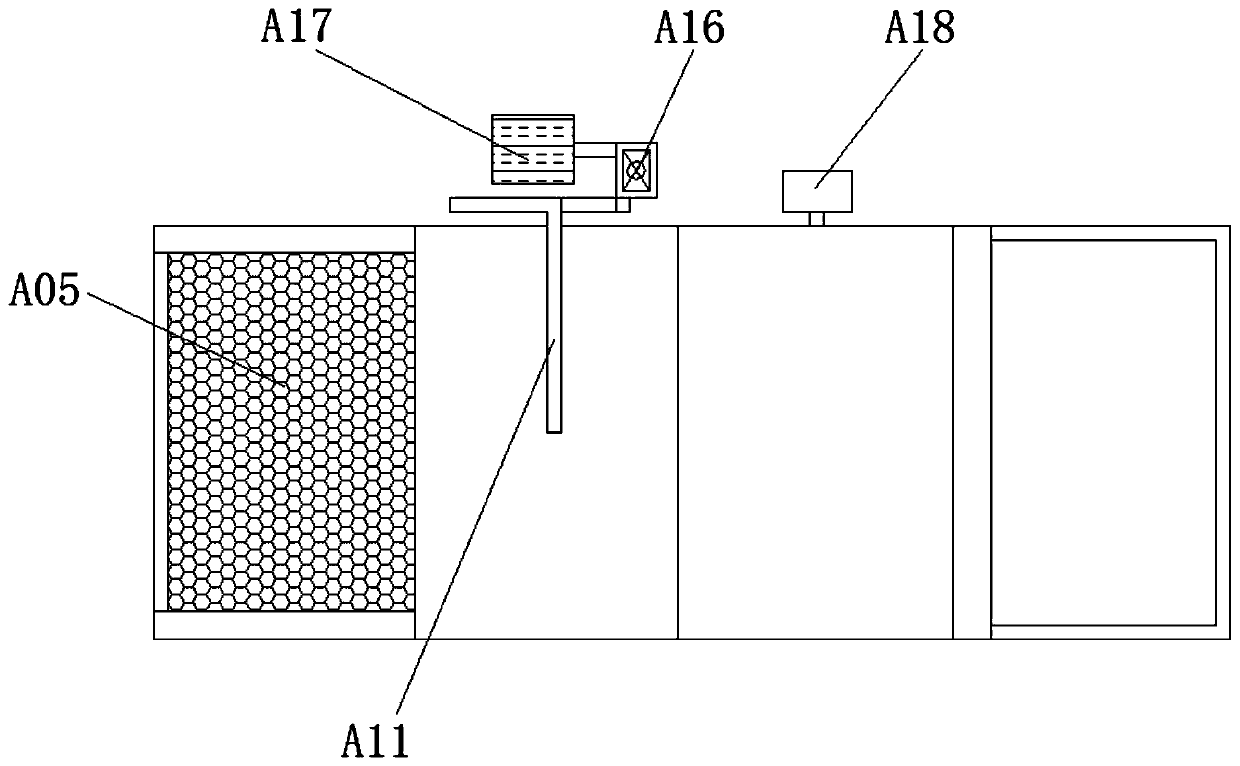

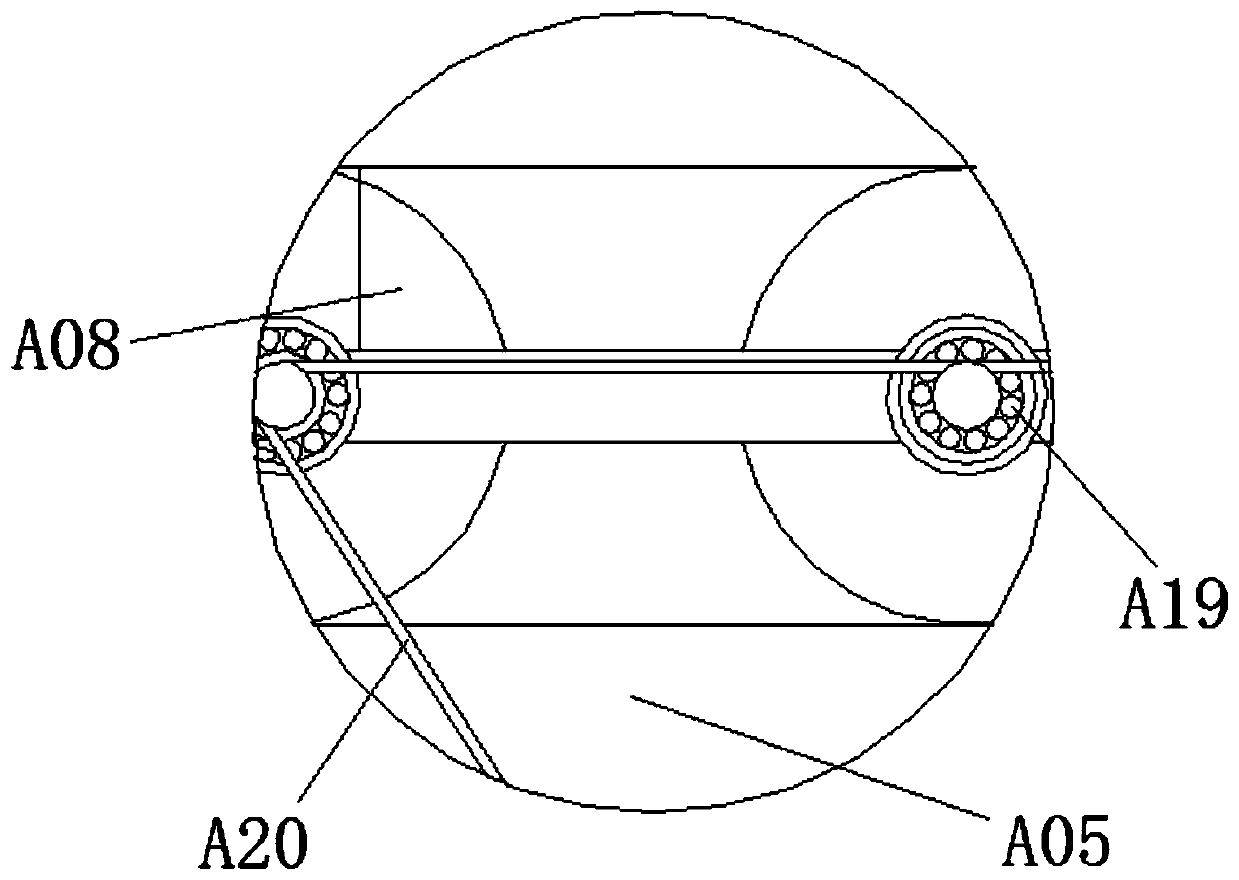

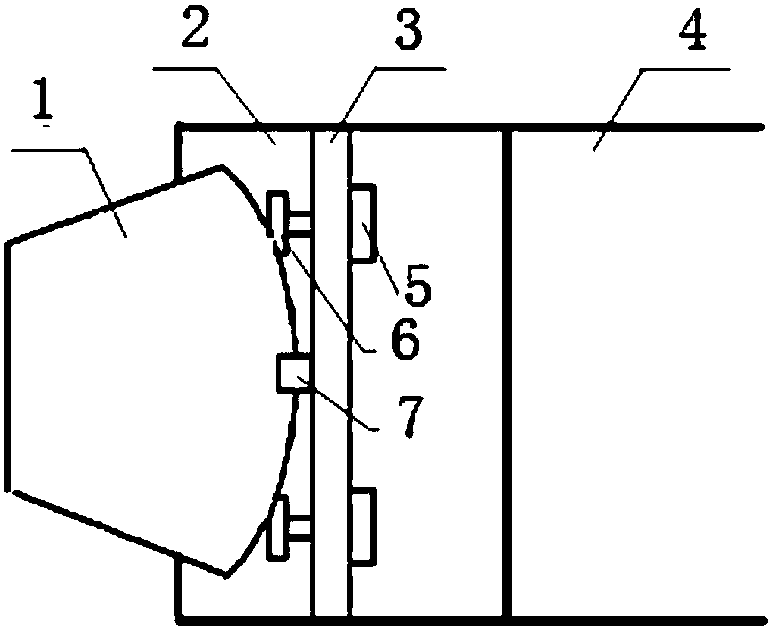

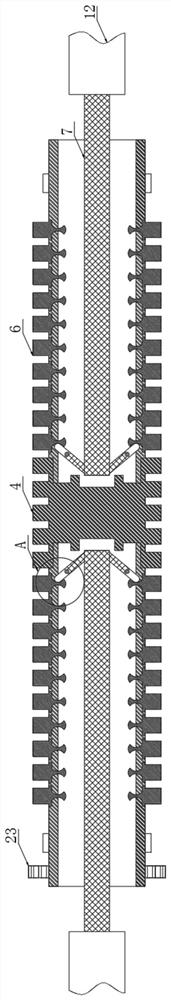

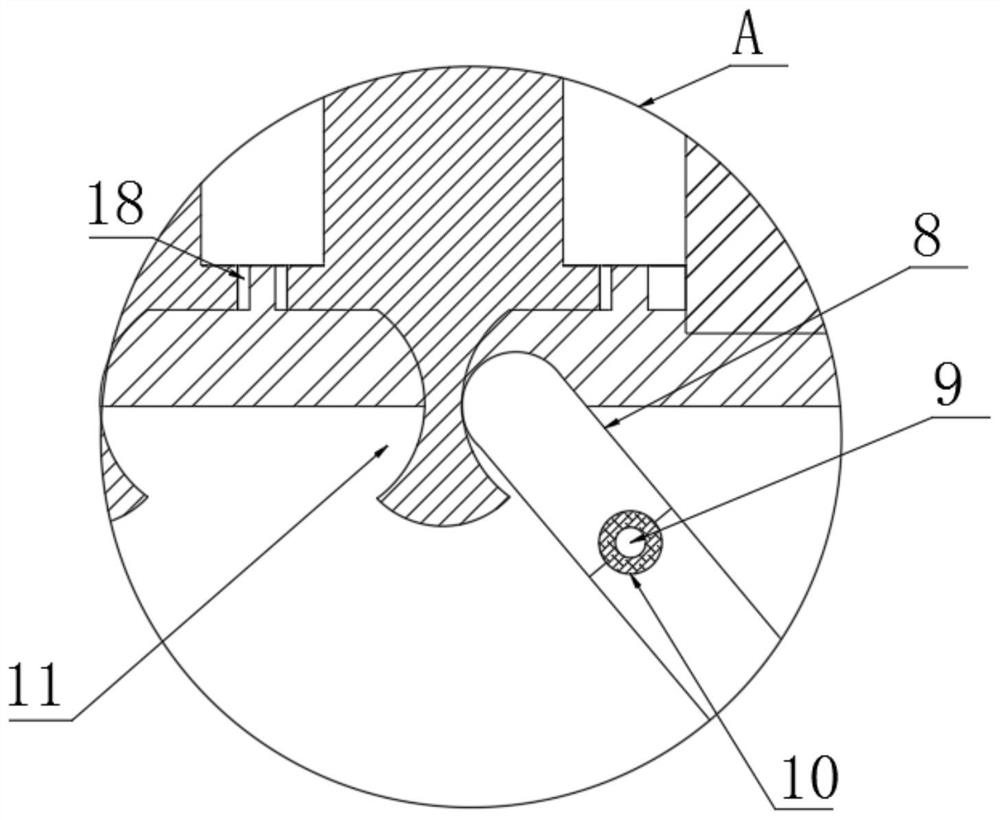

Variable-gap screw extrusion/dewatering integrated machine

PendingCN106082583AEasy to cleanSave waterSludge treatment by de-watering/drying/thickeningWater resourcesDrive motor

The invention relates to a variable-gap screw extrusion / dewatering integrated machine which comprises a drive motor (1), a variable-pitch shaft (2) and a cleaning system (4). The machine is characterized in that a stainless steel elastic filter screen (5) is sheathed on the variable-pitch shaft (2); a discharge end of the stainless steel elastic filter screen (5) is provided with a fixed pressure plate (6), and a feed end is provided with a movable pressure plate (7); both the fixed pressure plate (6) and the movable pressure plate (7) are installed on a guide shaft (8); and the movable pressure plate (7) is connected with a driving mechanism (9) for driving the movable pressure plate (7) to move along the guide shaft (8). The variable-gap screw extrusion / dewatering integrated machine can compact the driving mechanism to release compacting force in the shutdown cleaning process, so that the gap of the elastic filter screen naturally widens, and the gap of the filter screen is increased from 0.2-0.4mm to 2-3mm; and thus, the cleaning process is easier, and can save abundant water resources.

Owner:江苏鸿佑环保有限公司

Preset row-type pipes positioning device

InactiveCN106801515AImprove aestheticsEvenly spacedBuilding material handlingEngineeringBuilding construction

The invention discloses a preset row-type pipe positioning device. The preset row-type pipe positioning device comprises an inner sleeve (6), an outer sleeve (2) which is arranged outside the inner sleeve (6) in a sleeving mode and is in inserted connection with the inner sleeve (6), a first positioning unit (7) arranged at the end of the inner sleeve (6), which is away from the outer sleeve (2), and a second positioning unit (1) mounted on one end of the outer sleeve (2), which is arranged from the inner sleeve (6), wherein the inner sleeve (6) and the outer sleeve (2) can move relative to each other to adjust the inserting distance. The preset row-type pipe positioning device also comprises a positioning device for fixing the inserting position of the inner sleeve (6) and the outer sleeve (2). The preset row-type pipe positioning device can improve the overall aesthetic effects of preset row-type pipes and is high in construction efficiency, uniform in spacing and capable of effectively improving the uniformity of the spacing of the preset row-type pipes. The preset row-type pipes positioning device can effectively control the spacing of the preset row-type pipes and avoid personal errors and cumulative errors due to repeated measurement.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

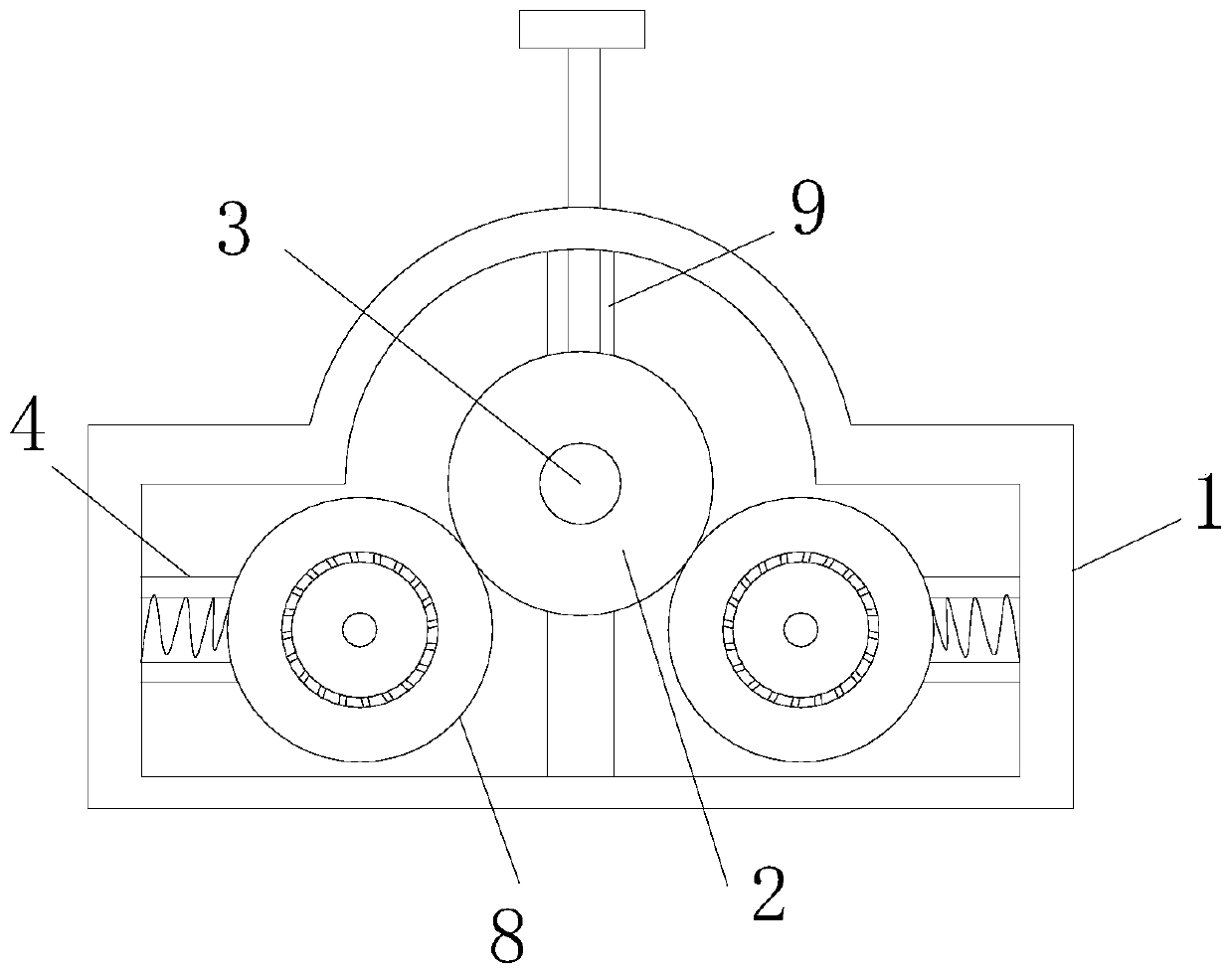

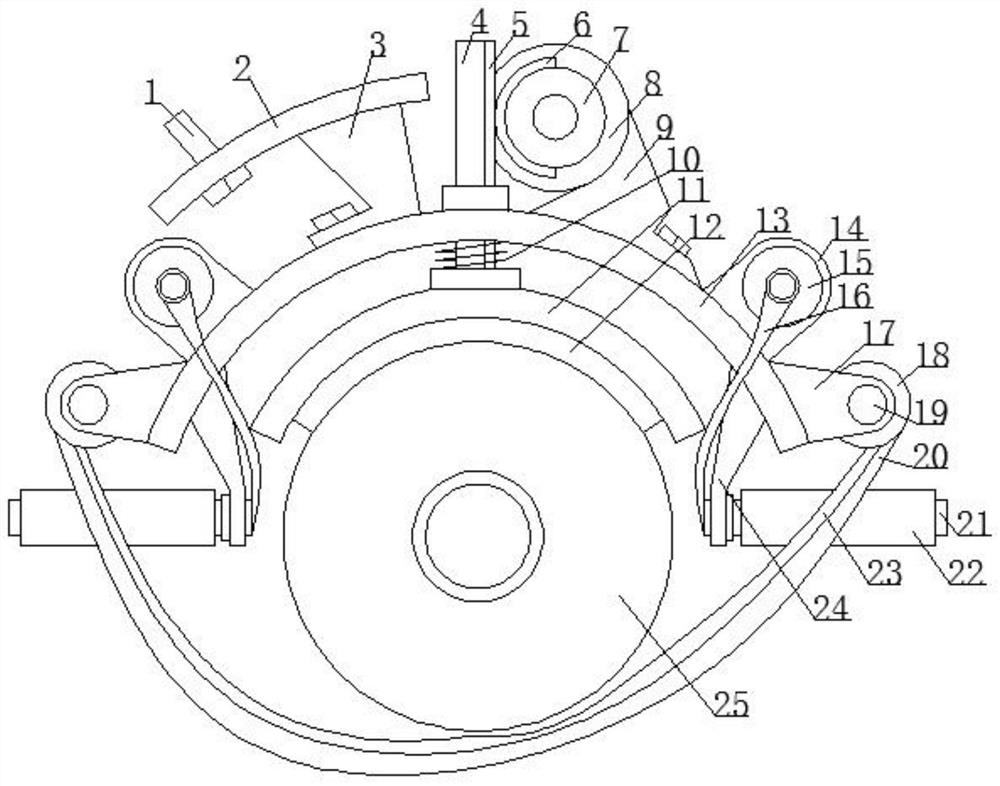

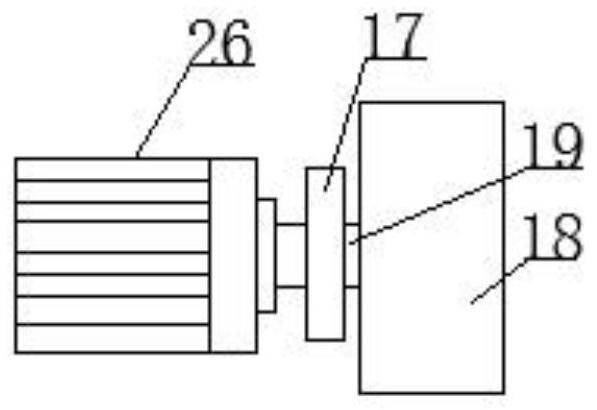

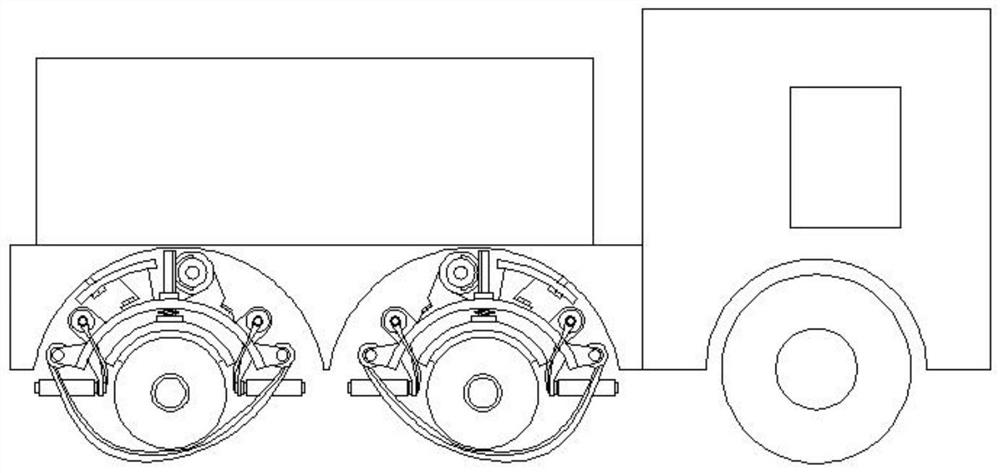

Control device for emergency stop of truck

InactiveCN111806405AQuick stopFast brakingBraking element arrangementsBraking action transmissionCoil springElectric machinery

The invention aims to solve a problem that a braking distance is not easy to shorten when a truck is braked emergently in the prior art. The invention discloses a control device for emergency stop ofa truck. The device comprises a wheel body and a cover plate. A connecting frame is fastened to a left side of an upper surface of the cover plate through screws. A mounting plate is welded at a top end of the connecting frame; a fastening screw is mounted on the mounting plate; and a rack is fastened to the right side of the upper surface of the cover plate through the screws, a first motor is fixedly installed at the top end of the rack, a rotary disc is installed in the middle of the first motor, a second rack is welded to the side surface of the rotary disc, a spiral spring is fixedly connected to the middle of the lower surface of the cover plate, and a sliding rod is arranged in the spiral spring. Through driving of the first motor, alternate friction is performed between wheel bodies through anti-skid layers, braking of a vehicle is accelerated, then through cooperation of air bags and air bag belts, control over the distance between the air bag belts can be achieved, dual braking can be performed on the vehicle conveniently, and the device is safer.

Owner:哈申其木格

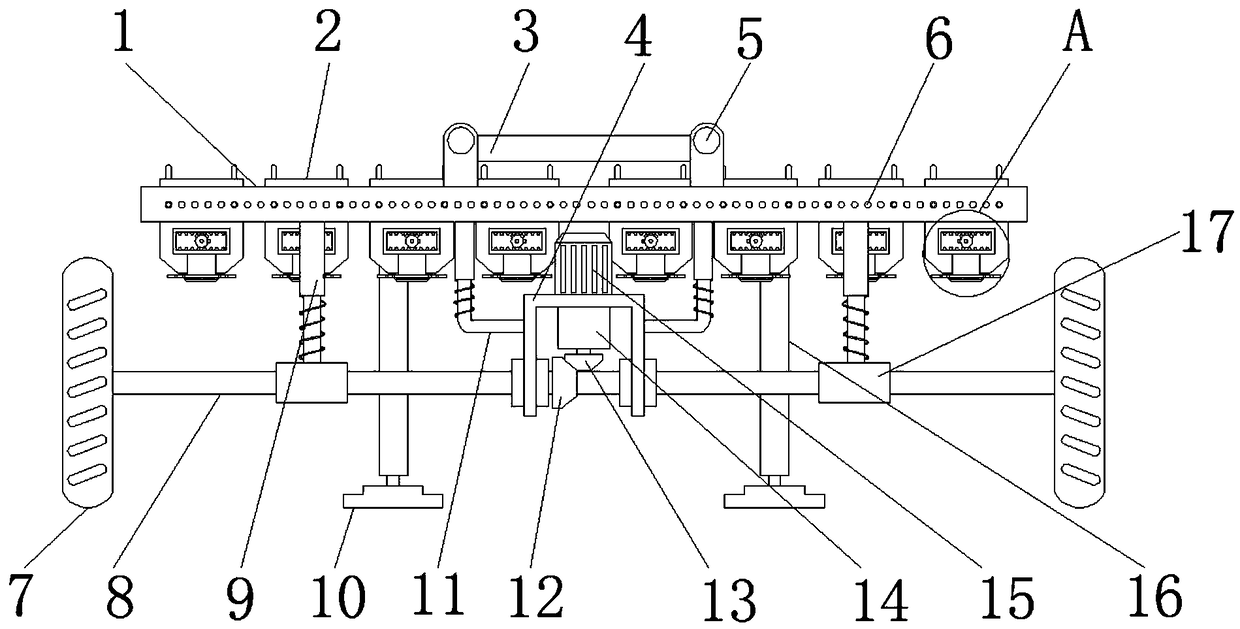

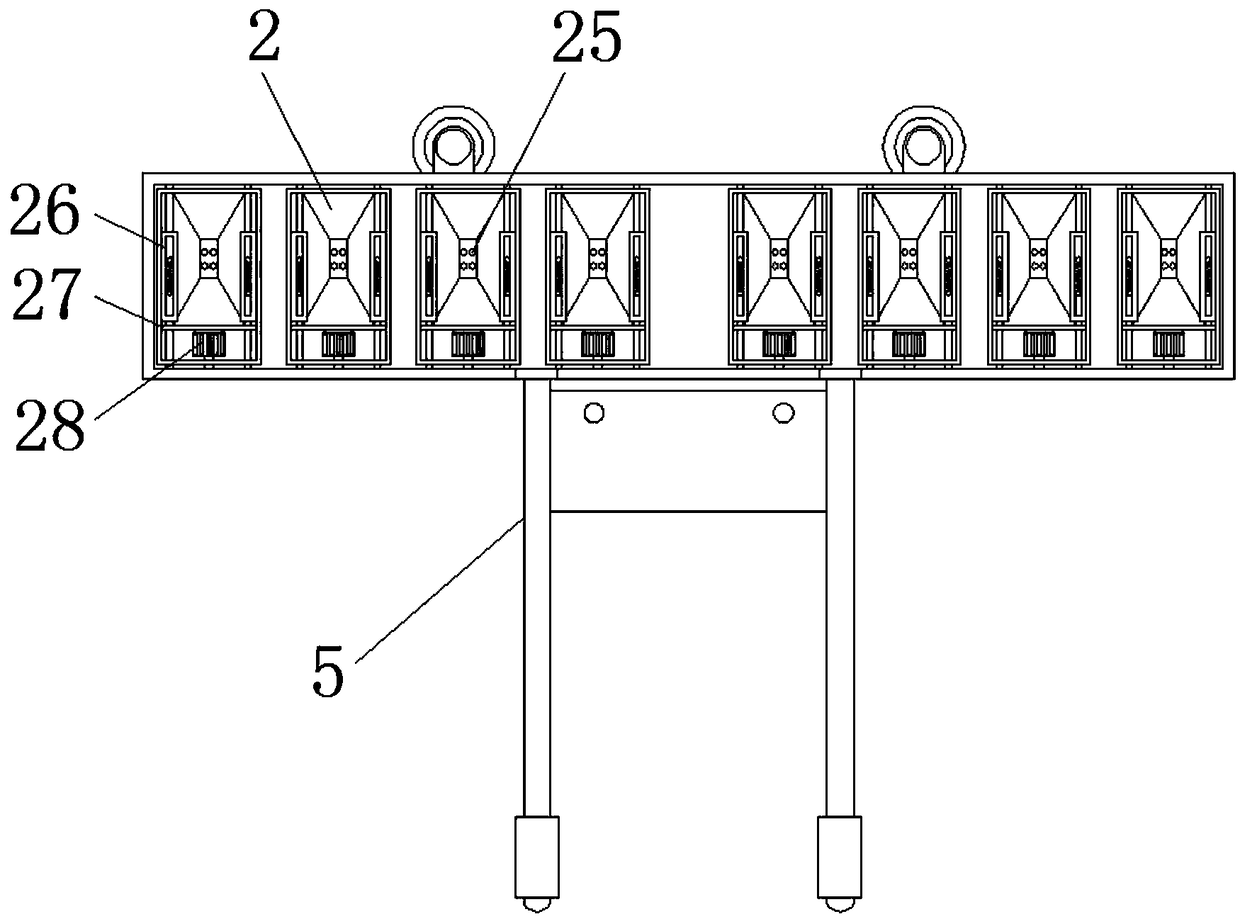

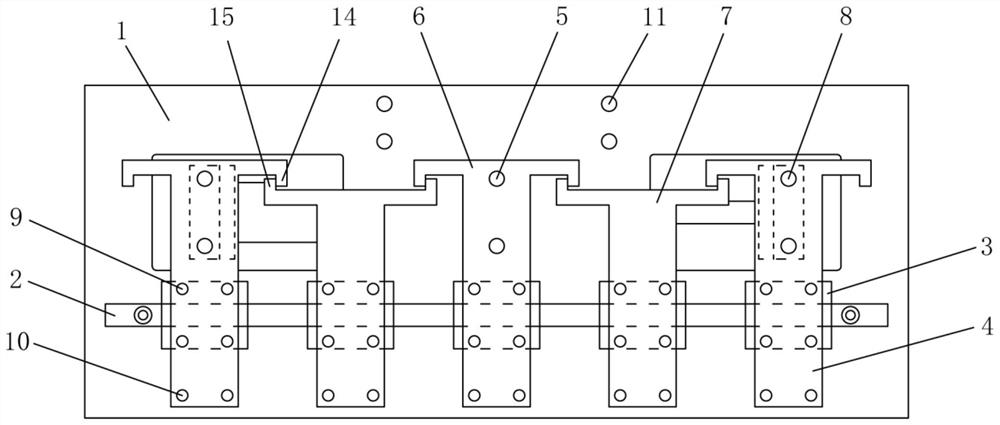

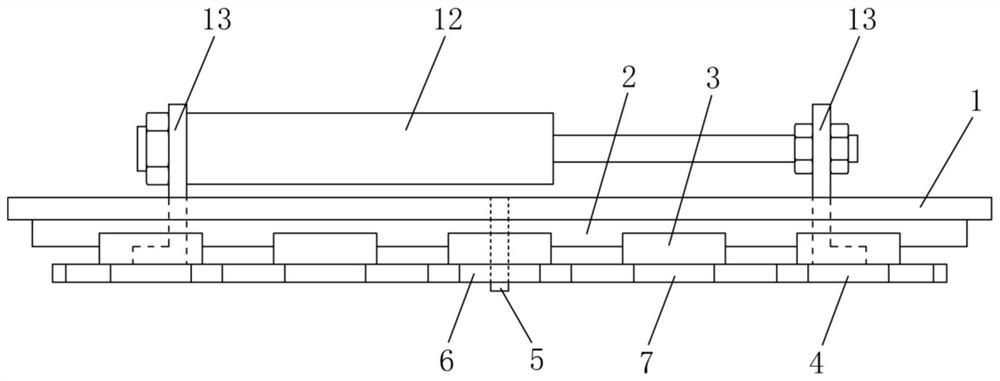

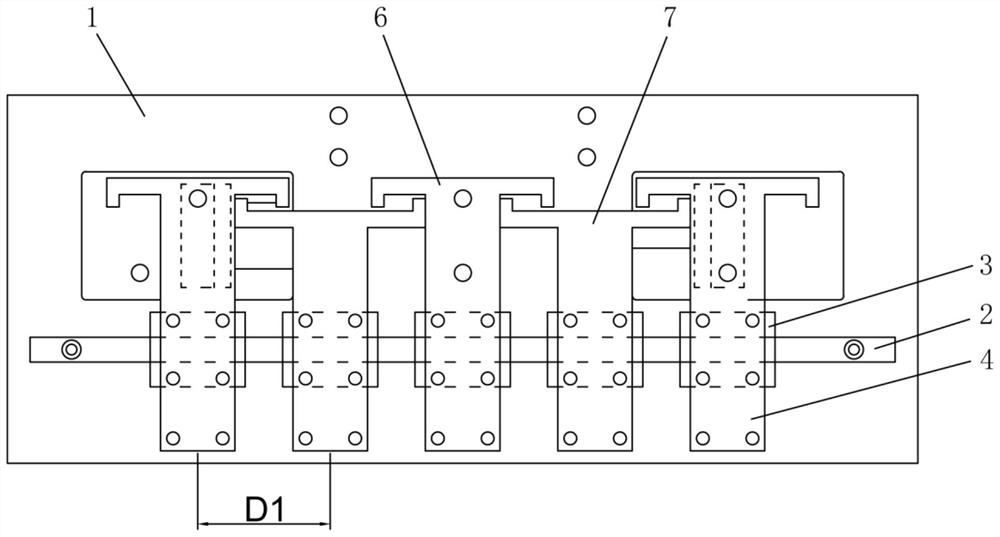

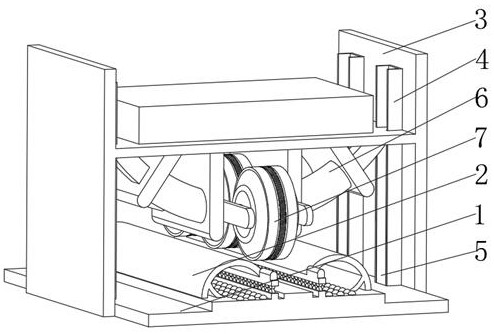

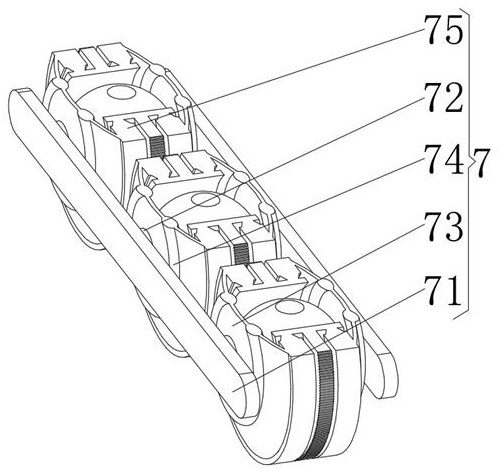

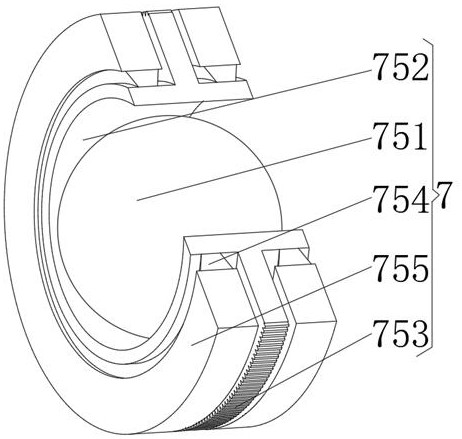

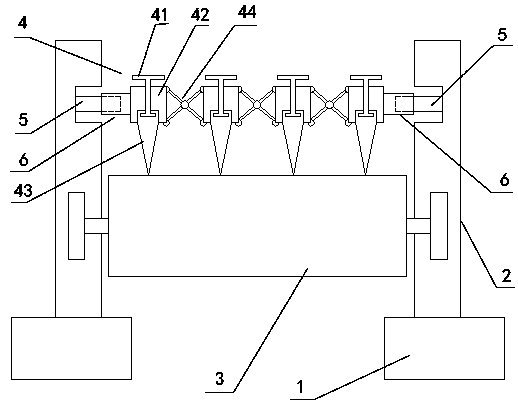

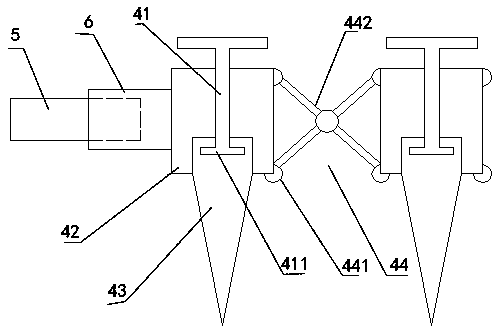

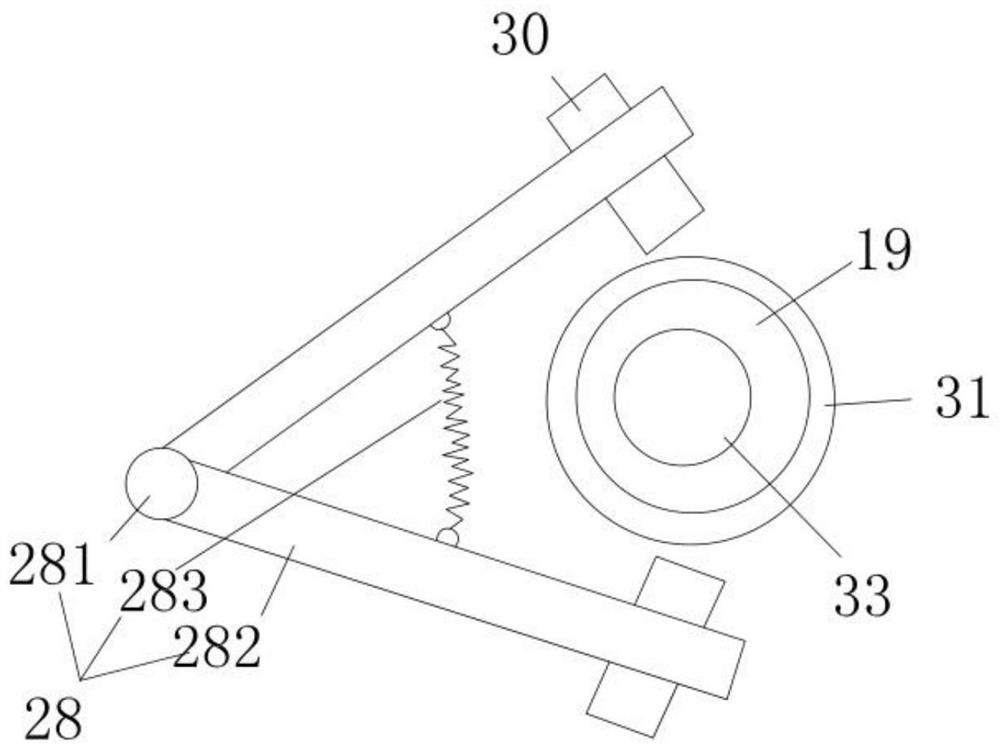

Variable-distance multi-working-head manipulator

PendingCN113263491ASpacing controlSave loading and unloading timeProgramme-controlled manipulatorGripping headsRobot handControl engineering

The invention relates to the technical field of manipulators, in particular to a variable-distance multi-working-head manipulator, which comprises a manipulator base plate installed on a robot or a moving module, wherein a plurality of limiting piece units and a driving component are evenly spaced on the manipulator base plate, the limiting piece units are used for installing grabbing working heads; and the driving component is used for driving the plurality of limiting piece units to move on the base plate at variable intervals. By adopting this structural arrangement, the manipulator base plate is installed on the robot or the moving module; during work, the driving component drives the plurality of limiting pieces to move on the manipulator base plate at variable intervals, so that intervals between the grabbing working heads installed on the plurality of limiting piece units are controlled, thus, a plurality of objects can be taken, placed and moved at a time, and the distance between the objects can be changed in a moving process, so that a loading time is greatly shortened, and the production efficiency is greatly improved.

Owner:深圳市诺信博通讯有限公司

Packaging bag sealing device

ActiveCN113501178ASpacing controlAvoid misalignmentWrapper twisting/gatheringTemperature controlHeat conducting

The invention discloses a packaging bag sealing device which specifically comprises a base, a limiting concave plate installed at the side, close to a conveying device, of a supporting frame plate, a lifting adjusting column installed at the bottom of an inner cavity of the limiting concave plate and a sealing device body installed in the middle of a temperature control device. The sealing device body comprises a heat conducting frame plate, a heat transfer column mounted at the side, away from the temperature control device, of a strip-shaped plate body, a spherical mounting plate mounted at the side, away from the strip-shaped plate body, of the heat transfer column, a heat insulation ring mounted on the spherical mounting plate and located at the outer side of the heat transfer column, and a sealing wheel mounted at the side, away from the heat transfer column, of the spherical mounting plate. The invention relates to the technical field of packaging machines. An operation track of equipment components is limited through the arrangement of the limiting concave plate, dislocation and deviation in the movement process are avoided, the equipment components are mutually protected, and meanwhile the arrangement of the lifting adjusting column facilitates control over the distance between the components.

Owner:南通永辉自动化科技有限公司

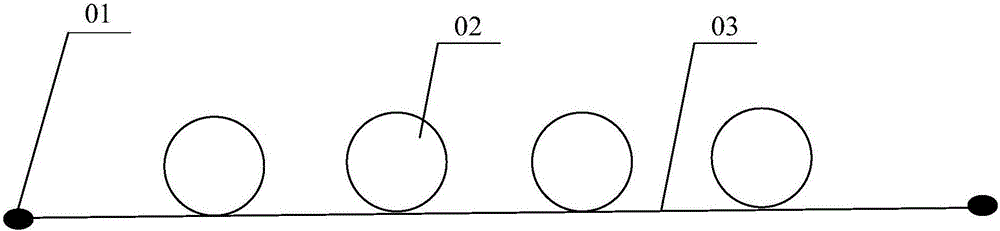

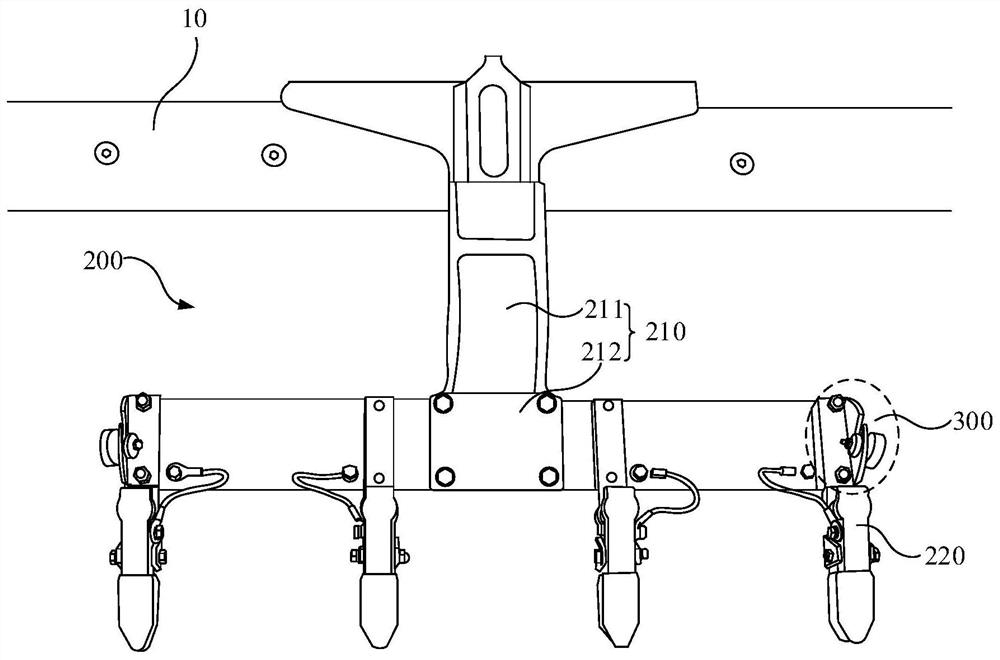

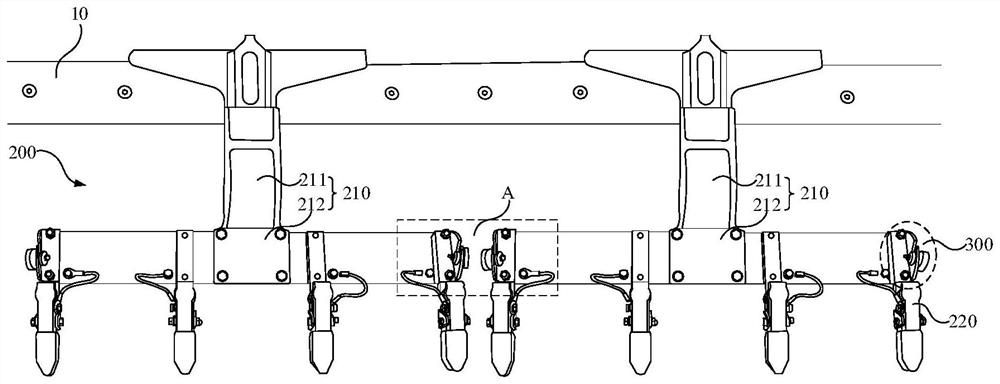

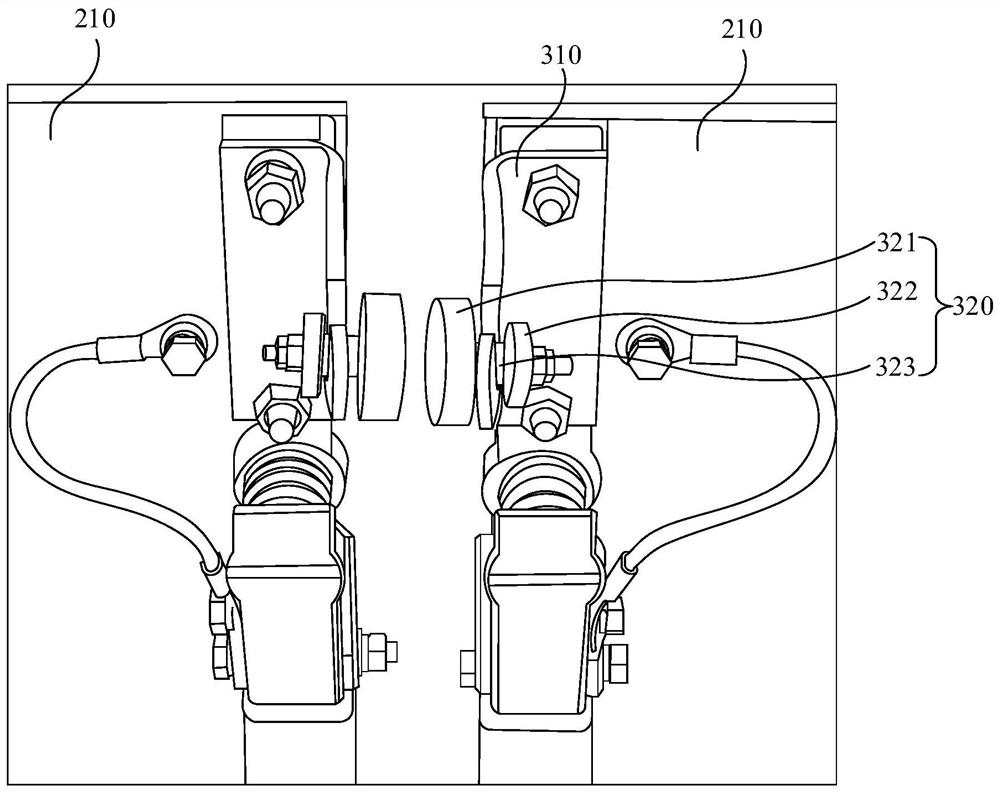

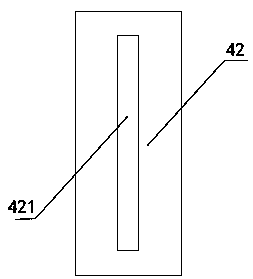

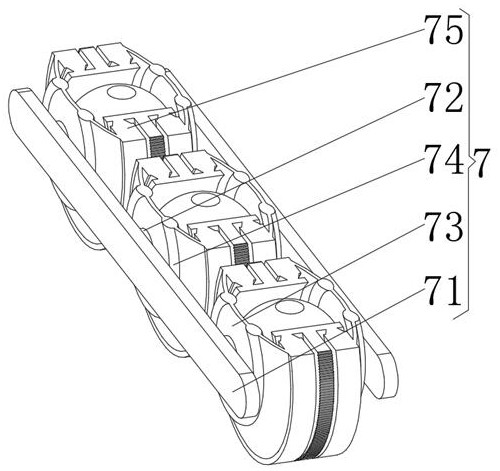

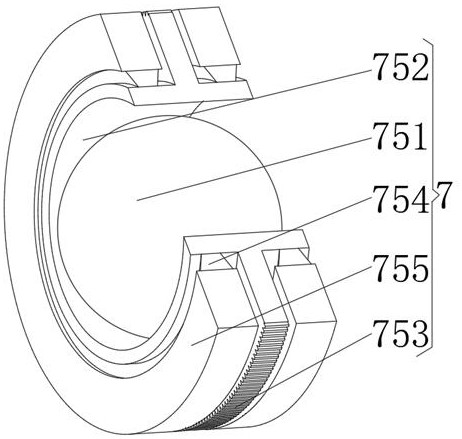

Vertical continuous electroplating hanging piece

The invention discloses a vertical continuous electroplating hanging piece. The vertical continuous electroplating hanging piece comprises a hanging frame and a spacing control unit. The hanging frame comprises a hanging tool and a clamp, one end of the hanging tool is hung on a rack, the other end of the hanging tool is connected with the clamp, and the clamp is used for clamping a workpiece. The spacing control unit is arranged at the end part of the hanging tool and is used for generating adsorption force / repulsive force to another adjacent hanging frame so as to control the spacing between the adjacent hanging frames. By means of the mode, the spacing between the adjacent hanging frames can be controlled, and therefore the electroplating uniformity is improved.

Owner:SHENNAN CIRCUITS

Slitting device for metalized film production and processing

The invention discloses a slitting device for metalized film production and processing. According to the technical scheme, the slitting device is characterized in that a through groove is formed in a fixing frame, an input roll and an output roll are fixedly installed at the two ends of the through groove correspondingly, a servo motor is fixedly installed at the position, located at the outer side of the fixing frame, of one end of the input roll, a friction mechanism is arranged in the output roll, the friction mechanism comprises an actuator and an unfolding piece, and the actuator is in threaded connection with the unfolding piece through a sliding block. According to the device, the friction mechanism is arranged, the friction force between the unfolding piece and the output roll is increased through the friction mechanism, and therefore it is guaranteed that when the input roll works to drive a metalized film on the output roll to be wound to the input roll, the metalized film between the input roll and the output roll is always in a tight state due to the increase of the friction force, and cutting is convenient, and a cutter is not prone to being adhered by the metalized film, so that the metalized film is inclined, and the cut edge of the metalized film is not flush.

Owner:芜湖鑫国电子科技有限公司

Electric purification assembly and air purifier

PendingCN111359779AGuaranteed fixed effectGuaranteed uniformityMechanical apparatusLighting and heating apparatusAir purifiersEngineering

The invention relates to the technical field of household appliances, in particular to an electric purification assembly and an air purifier. The electric purification assembly comprises a first sideplate and a second side plate which are oppositely arranged in pairs, wherein an accommodating space is defined by the first side plate and the second side plate; a repelling pole assembly, arranged in the accommodating space and comprising a plurality of repelling pole metal sheets arranged at equal intervals and a plurality of supporting pieces erected between the two first side plates, and therepelling pole metal sheets being arranged on the supporting pieces in a penetrating mode; an earth electrode assembly, arranged above the repelling pole assembly and comprising a plurality of earth electrode metal sheets which are arranged at equal intervals, the earth electrode metal sheets being arranged on the supporting piece in a penetrating mode, and the earth electrode metal sheets and therepelling electrode metal sheets being arranged in a staggered mode; and a plurality of discharge assemblies, arranged above the earth electrode assembly, and two ends of each discharge assembly being respectively arranged on the two second side plates. through arranging the repelling pole metal sheets and the earth electrode metal sheets on the supporting piece at equal intervals, the purification efficiency is guaranteed, and meanwhile, the generation of ozone can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Cleaning device for production of clothing fabric

InactiveCN110453406AComprehensive cleaningSpacing controlTextile treatment by spraying/projectingTextile treatment carriersElectric machineryEngineering

The invention discloses a cleaning device for production of a clothing fabric. The cleaning device comprises a machine body, rollers and a water pipe, wherein bottom legs are fixed on the lower portion of the bottom of the machine body, the right side of the outer wall of the machine body is provided with a clamping groove, the inner portion of the clamping groove is connected with a fabric box, the upper portion of the left side of the top of the machine body is provided with a first workbench, a second bearing is arranged below a center line of the first workbench, a supporting column is arranged under the second bearing, the rollers are fixed above the first workbench, a motor is arranged under the roller, and the right side of the first workbench is provided with a second workbench. The cleaning device for production of the clothing fabric has the advantages that through the clamping groove in the machine body, the fabric box can fit the clamping groove, thereby making the fabric box installed on the machine body or disassembled from the machine body and making the cleaned fabric placed in the fabric box, so that people can directly take away the fabric box and do not need to take the fabric out of the cleaning device separately and then place the fabric into another storage device.

Owner:刘博

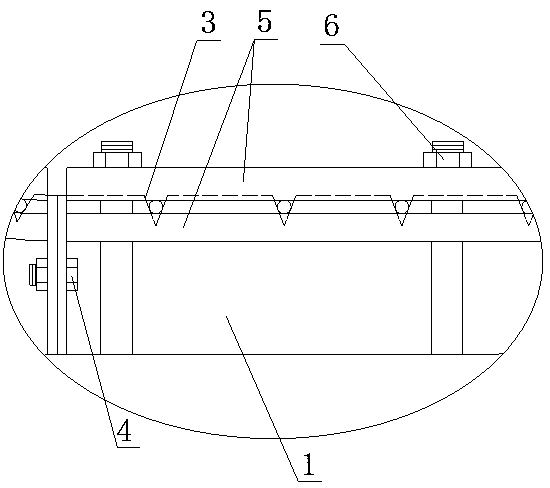

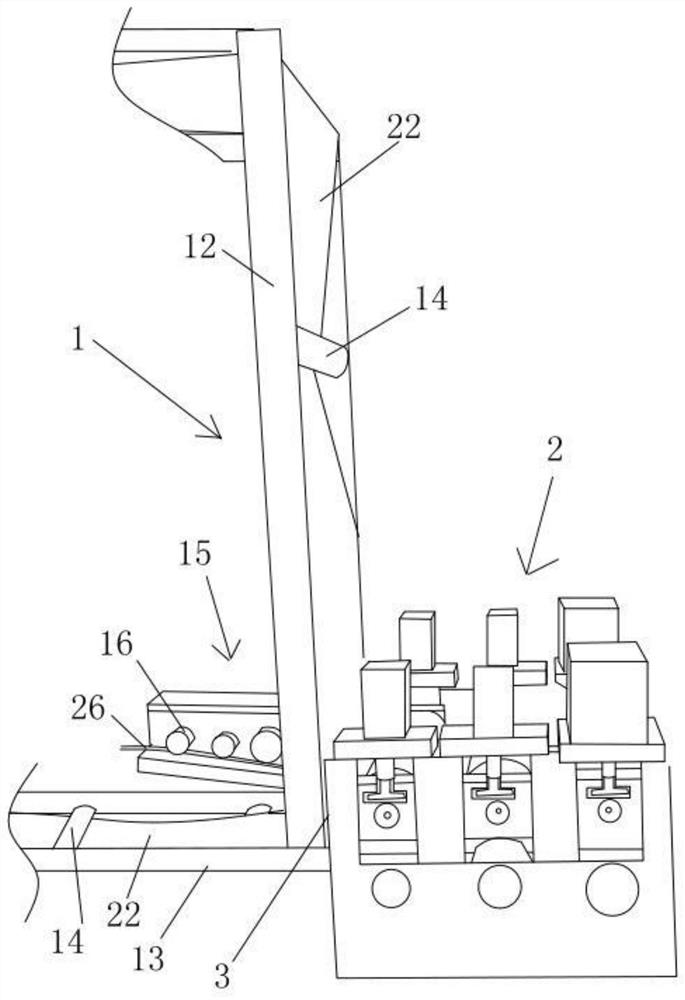

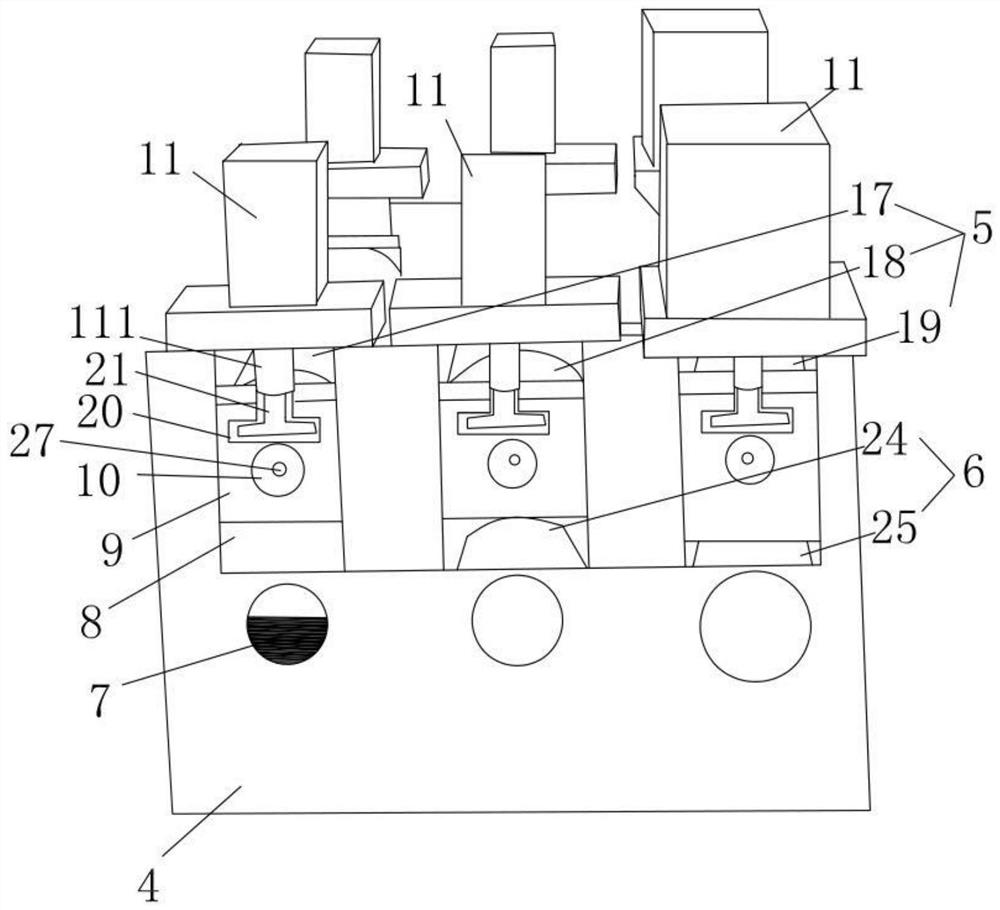

A pitch-adjustable non-woven fabric slitting machine

ActiveCN107604627BAdjustable spacingSpacing controlSevering textilesEngineeringMechanical engineering

The invention discloses a non-woven fabrics slitter with adjustable spacing comprising a base, supports installed at two sides of the base, a discharge roller installed on the supports and a slitter mechanism; the slitter mechanism is installed above the discharge roller; the slitter mechanism comprises multiple connecting blocks, multiple adjusting screws, multiple cutting blades and multiple spacing adjusting mechanisms. By means of the slitter of the invention, the cutting depth and cutting spacing of blades can be adjusted.

Owner:盐城恒天无纺布科技有限公司

A wide range of wheat and corn precision fertilization equipment and method thereof

ActiveCN109328581BEasy to assembleEasy to disassembleFertiliser distributersFertilising methodsAgricultural scienceAgricultural engineering

The invention discloses wheat and corn precision fertilization equipment with a wide application range and a method thereof. The precision fertilization equipment comprises a rectangular frame and a granular fertilizer storage box. The method comprises the following steps: performing first plowing on a land before fertilization; measuring the spacing between two adjacent sowing positions through asteel tap; squeezing two symmetrically arranged L-shaped poke rods and compressing a spring 3 to ensure that one end of each L-shaped poke rod moves out of a clamping groove; and carrying out operations in sequence to disassemble all granular fertilizer storage boxes. By measuring the spacing between adjacent seedlings, and the spacing between two granular fertilizer storage boxes correspondinglyarranged in a rectangular frame, the spacing between adjacent granular fertilizer storage boxes is convenient to adjust, the application range is enlarged, the limitation is small, the spacing between adjacent granular fertilizer storage boxes can be controlled to correspond to adjacent sowing places, the fertilizing precision is improved, the operation process is time-saving and labor-saving, shaking is generated through buffering of a shock absorber 1 and a shock absorber 2, and convenience is provided for a handheld operation process.

Owner:董保成

Corner water stop steel plate equipped with fixing device and construction method

ActiveCN109811801AEasy to weldAvoid enteringArtificial islandsProtective foundationArchitectural engineeringSteel plates

The invention discloses a corner water stop steel plate equipped with a fixing device and a construction method, and belongs to the technical field of building construction. The steel plate is provided with a first right angle plate and a second right angle plate, one end of the first right angle plate is welded with one end of the second right angle plate, a first weld plate and a second weld plate are welded at tail ends of the first right angle plate and the second right angle plate respectively, a first seam allowance is formed between the first weld plate and the first right angle plate,a second seam allowance is formed between the second weld plate and the second right angle plate, welding length can be conveniently controlled through the first seam allowance and the second seam allowance, and the first weld plate and the second weld plate can drain water downwards from a waterproof groove, and the waterproof effect of weld seams is ensured. The steel plate also comprises the fixing device, the distance between water stop steel strips and the first weld plate and the second weld plate is adjusted by an adjusting sleeve, and thus, welding quality is effectively ensured, recycling of the fixing device is realized, and the cost is saved.

Owner:CHINA MCC17 GRP

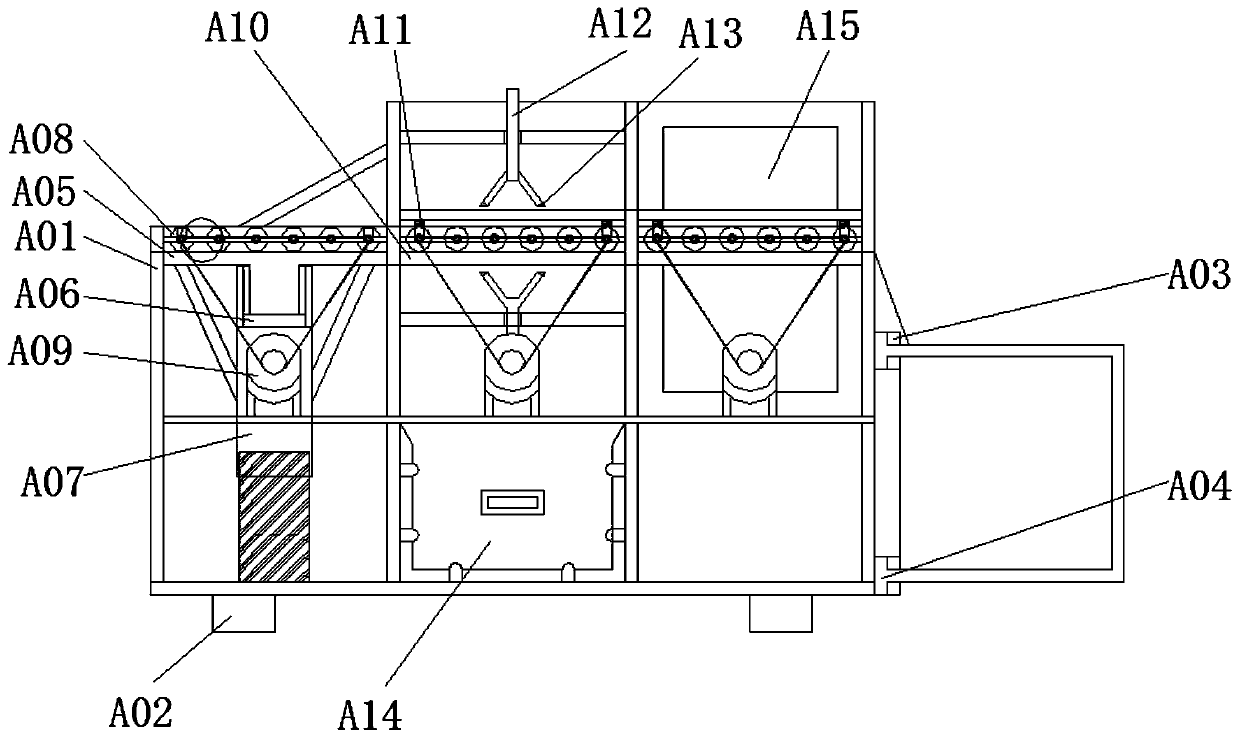

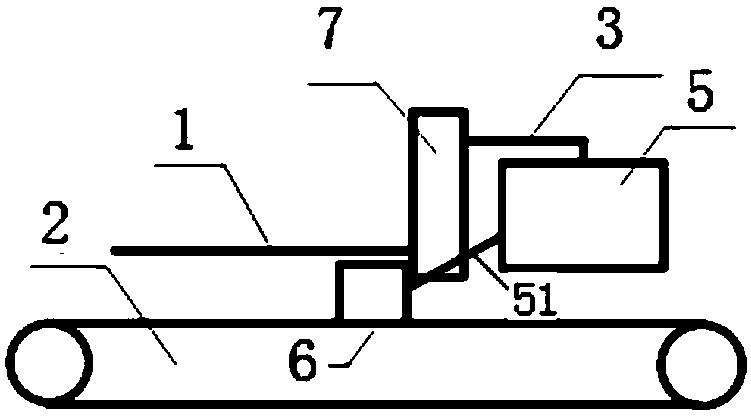

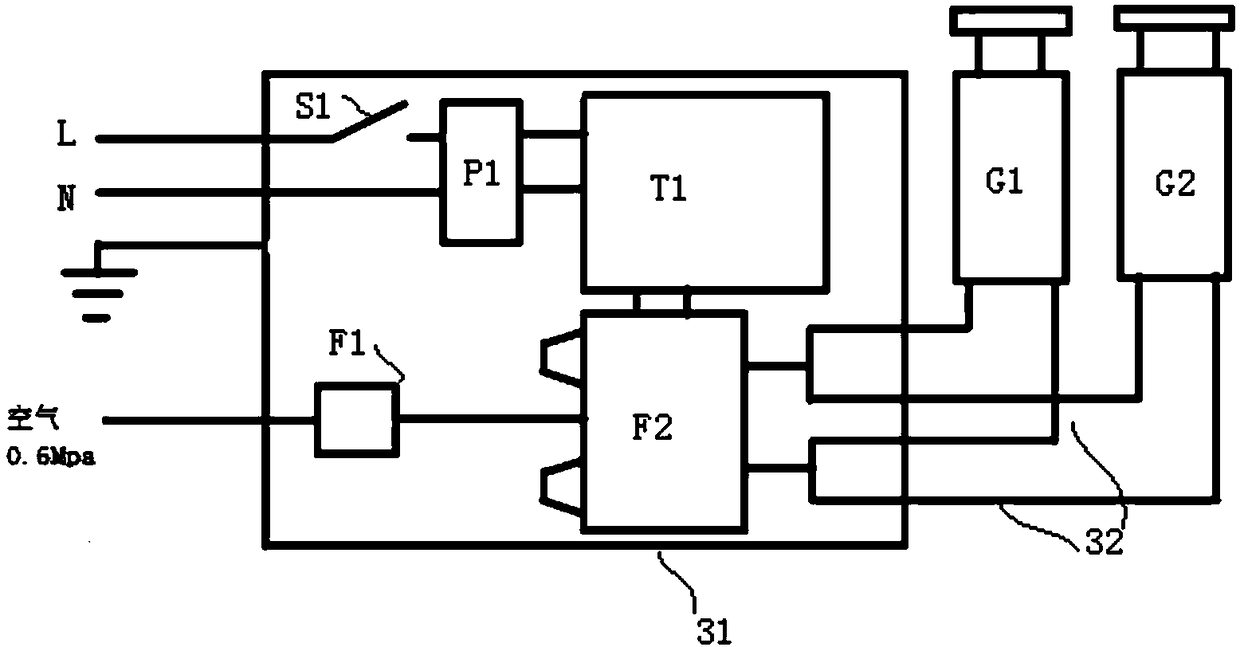

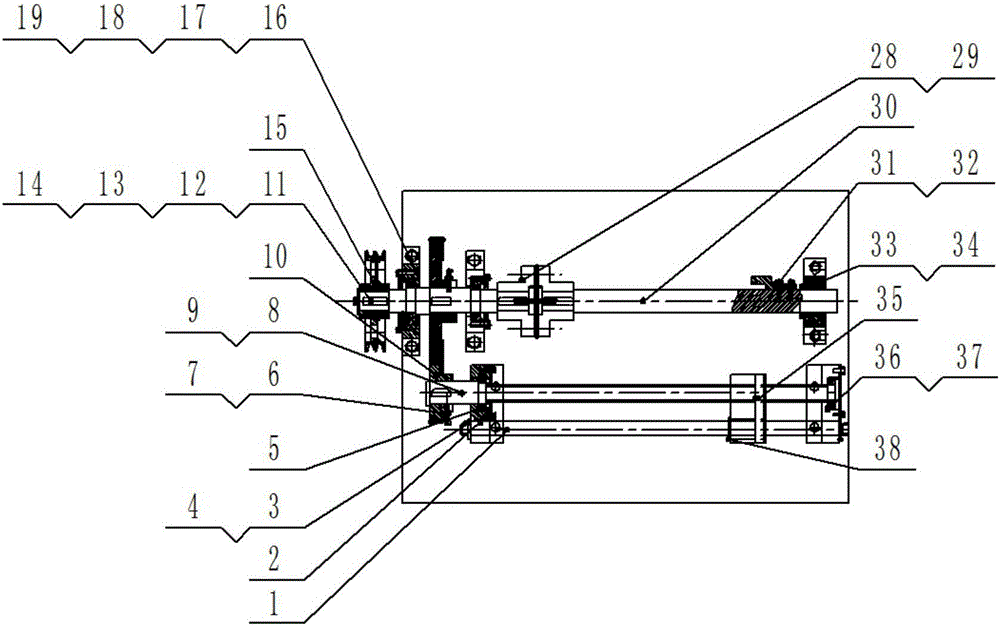

Separation distance control device and method for silicon steel sheet feeding for painting

ActiveCN108067383ASpacing controlImprove and maintain qualitySpraying apparatusGas cylinderElectronic control system

The invention discloses a separation distance control device and method for silicon steel sheet feeding for painting. The separation distance control device and method for silicon steel sheet feedingfor painting comprises a mechanical execution system and an electronic control system. The mechanical execution system comprises a body, a gas cylinder part, a positioning block and a supporting block. The positioning block and the gas cylinder part are fixed to the body. The gas cylinder part is provided with an inclined piston rod with a certain angle away from the horizontal surface. The supporting block is connected to the piston rod. The positioning block is used for positioning a stamping sheet. The supporting block is used for supporting the stamping sheet. The electronic control systemis connected with the gas cylinder part and controls the piston rod of the gas cylinder part to stretch out and draw back within the set time, so that the supporting block moves back and forth between the position of stretching out and the position of drawing back. The position of stretching out is the position where the lower surface of the supporting block making contact with a conveyer belt for silicon steel sheets. The position of drawing back is the position, away from the conveyer belt for the silicon steel sheets, of the supporting block. The separation distance control device can haveaccurate control over the separation distance between two adjacent silicon steel sheets which are fed, the operation is easy and convenient, and a very good effect is achieved on improving and keeping the painting quality of stamping sheets.

Owner:上海电气集团上海电机厂有限公司

Mask sheet making machine

PendingCN112158638AExtended service lifeCompact structureArticle deliveryClothes making applicancesTextile printerEngineering

The invention relates to the technical field of mask production equipment, and particularly relates to a mask sheet making machine. The mask sheet making machine structurally comprises a sheet conveying mechanism and a sheet die cutting mechanism, wherein the die cutting mechanism is used for conducting die pressing and cutting on sheets; the die cutting mechanism comprises a station frame; a diepressing and cutting roller set which is horizontally placed is arranged on the station frame; a pillow roller set and an ultrasonic vibrator die used for printing are arranged under the die pressingand cutting roller set; two symmetrical guide grooves are formed in the station frame; each guide groove extends in the vertical direction; a sliding block is arranged in each guide groove; the two ends of a central spindle of the die pressing and cutting roller set are sleeved with tensioning sleeves; the two ends of the central spindle with the tensioning sleeves are connected with the two sliding blocks in a one-to-one corresponding and inserted manner and rotate; an adjusting air cylinder is arranged at the top end of each guide groove; a piston rod of each adjusting air cylinder buckles the sliding block in the corresponding guide groove; each adjusting air cylinder is connected with an adjusting valve; and the adjusting air cylinders can accurately and stably control the distance andpressure between rollers. The whole mask sheet making machine has the beneficial effects of being compact in structure and long in service life.

Owner:蔡必建

A plastic film cutting device for convenient waste collection

The invention discloses a plastic film cutting device which is convenient for collecting waste materials. It comprises a base, and columns are arranged symmetrically on the upper surface of the base, and an unwinding roller and a winding roller are respectively arranged between the columns; the unwinding roller and the The winding rollers are all connected to the column through bearings, the surface of the winding rollers is symmetrically provided with chute, the surface of the winding roller is provided with a separating part slidingly connected with the chute, and the inside of the winding roller is provided with a moving rod, An extruding rod is arranged on the moving rod, and the moving rod and the extruding rod are hinged through a rotating shaft. A torsion spring is sleeved on the surface of the rotating shaft. , the position of the column corresponding to the moving rod is provided with an electric push rod; the present invention automatically rewinds the cut waste materials while cutting the plastic film, so as to avoid random scattering of waste materials on the ground and improve the efficiency of cleaning and recycling.

Owner:东营欣邦电子科技有限公司

A packaging bag sealing device

ActiveCN113501178BSpacing controlAvoid misalignmentWrapper twisting/gatheringTemperature controlThermal insulation

The invention discloses a packaging bag sealing device, which specifically includes: a base, a limiting concave plate installed on the side of the supporting frame plate close to the conveying device, and a limiting concave plate installed at the bottom of the inner cavity of the limiting concave plate Lifting and adjusting columns, and a sealing device installed in the middle of the temperature control device, the sealing device includes: a heat conduction shelf plate, and a heat transfer plate installed on the side of the strip-shaped plate away from the temperature control device column, and a spherical mounting plate installed on the side of the heat transfer column away from the bar body, and a heat insulation ring installed on the spherical mounting plate outside the heat transfer column, and installed on the spherical surface The mounting plate is away from the sealing wheel on the side of the heat transfer column. The invention relates to the technical field of packaging machinery. The running track of the equipment components is limited by the setting of the limiting concave plate, avoiding misalignment and offset during the movement, and mutual protection of the equipment components. At the same time, the setting of the lifting and adjusting columns is convenient for controlling the spacing of the components.

Owner:南通永辉自动化科技有限公司

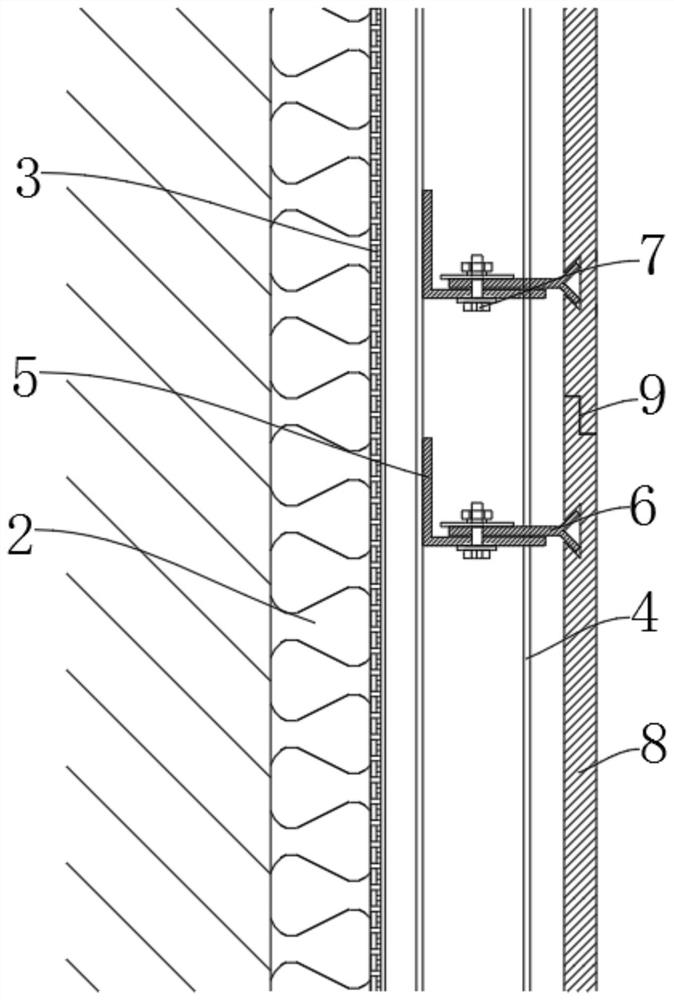

Fiber cement board dry hanging structure

The invention discloses a fiber cement board dry hanging structure, and belongs to the technical field of fiber cement board dry hanging. The fiber cement board dry hanging structure comprises a fiber cement board, an inverted trapezoidal groove is formed in the fiber cement board, a dry hanging piece is clamped in the inverted trapezoidal groove, a lining plate matched with the inverted trapezoidal groove is inserted into the inverted trapezoidal groove, and the dry hanging piece is connected into the lining plate; the inverted trapezoidal groove is provided with a hanging piece installation reserved opening, the grooving depth of the inverted trapezoidal groove is 6 mm, and the fiber cement board is connected with a stand column through the dry hanging piece. The fiber cement board dry hanging structure has no requirement on the length and width of a fiber cement board material, the installation process has no influence on a facing layer, the installation process is simple, and the requirement of dry hanging of a large-breadth board on an outer wall is met.

Owner:SHANDONG LUTAI BUILDING MATERIAL SCI & TECH GRP CO LTD

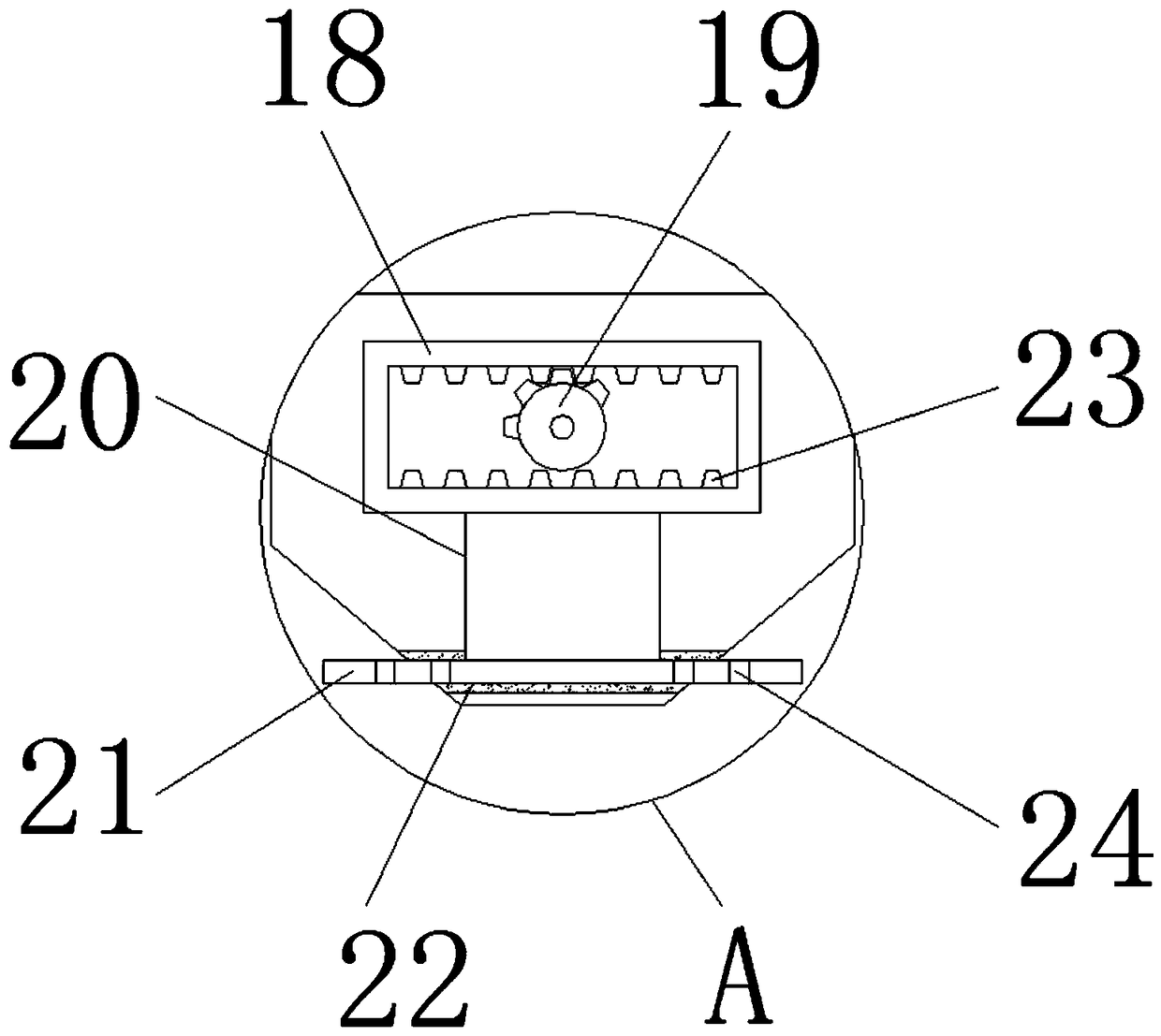

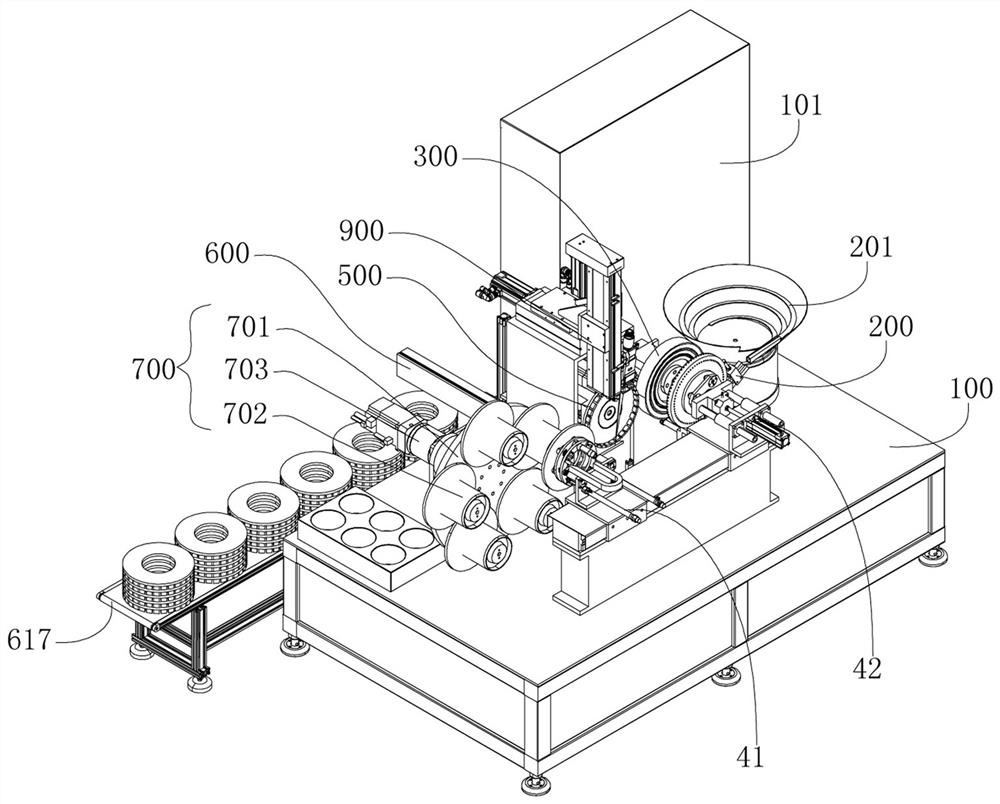

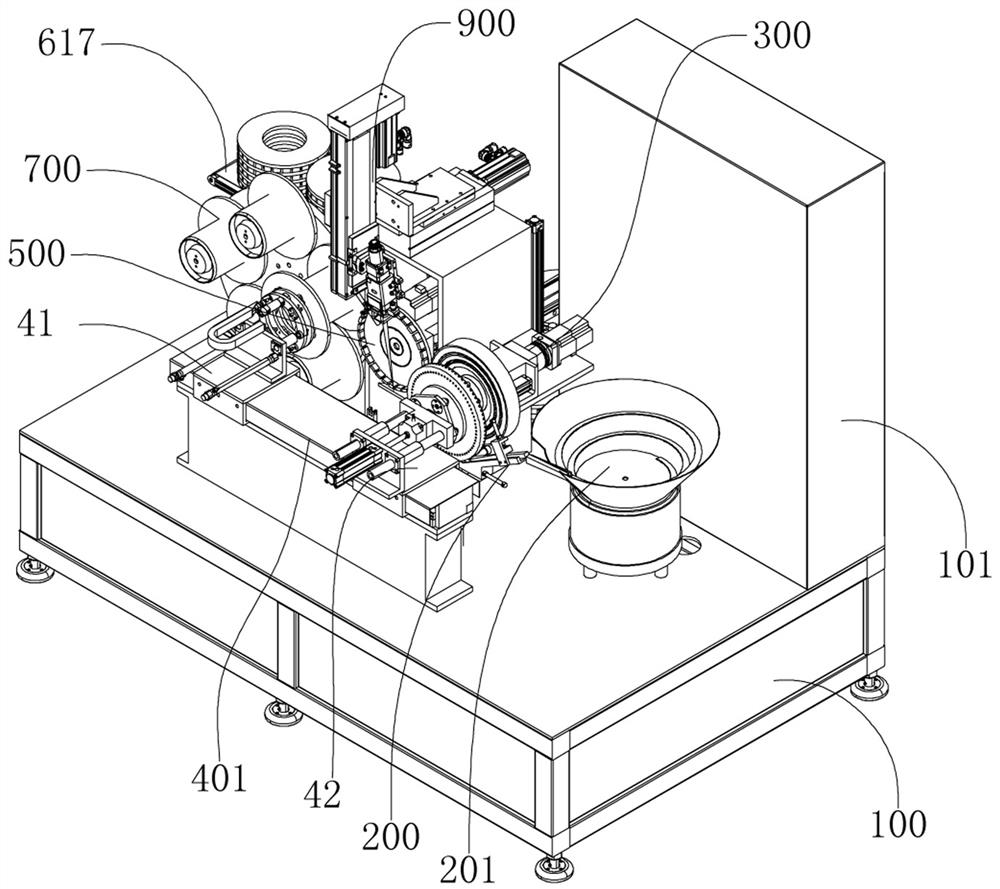

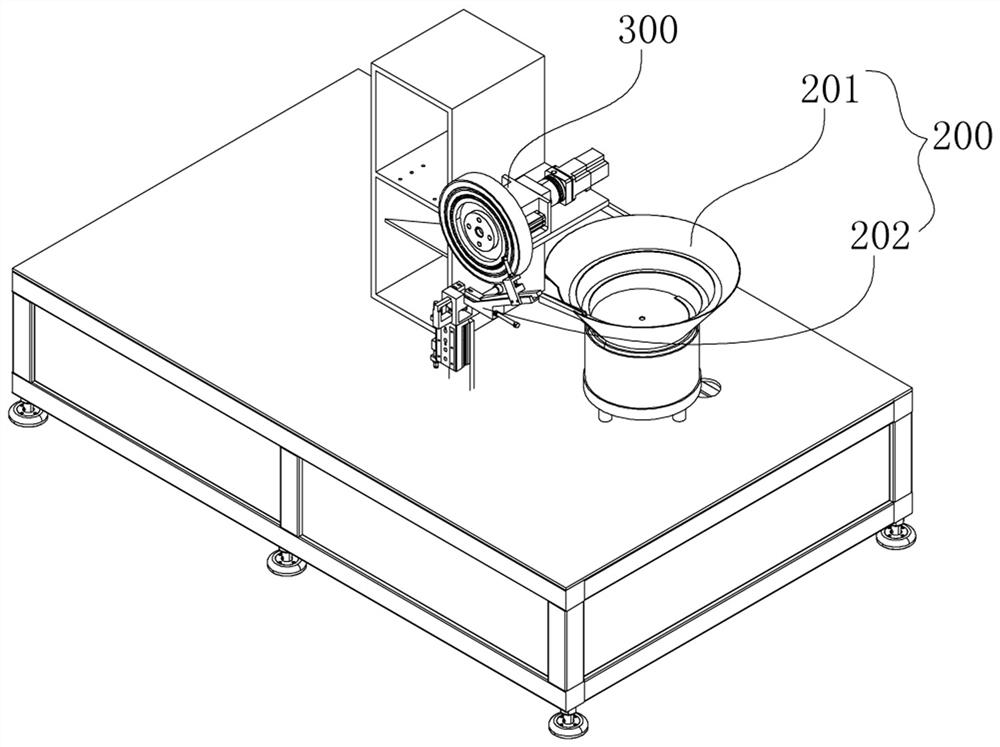

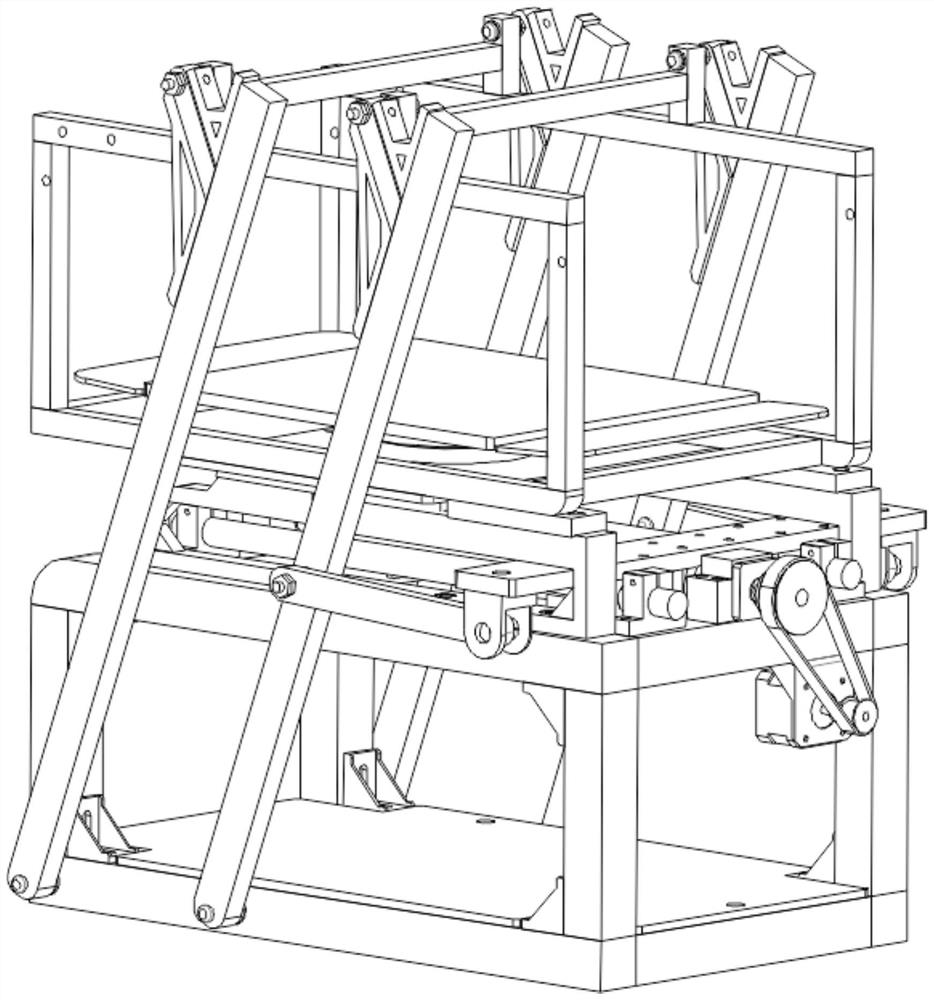

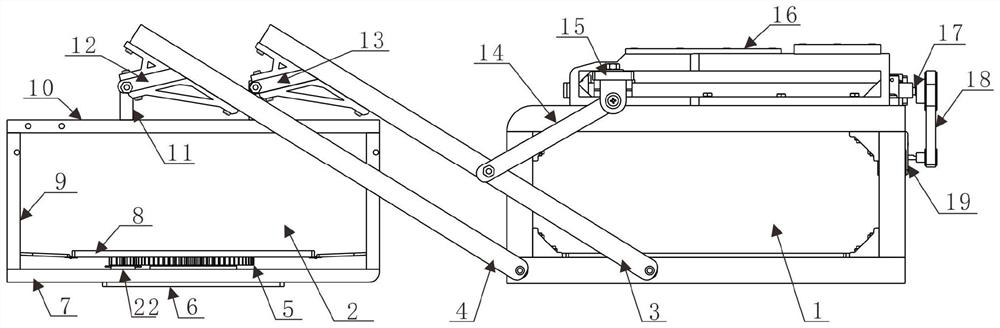

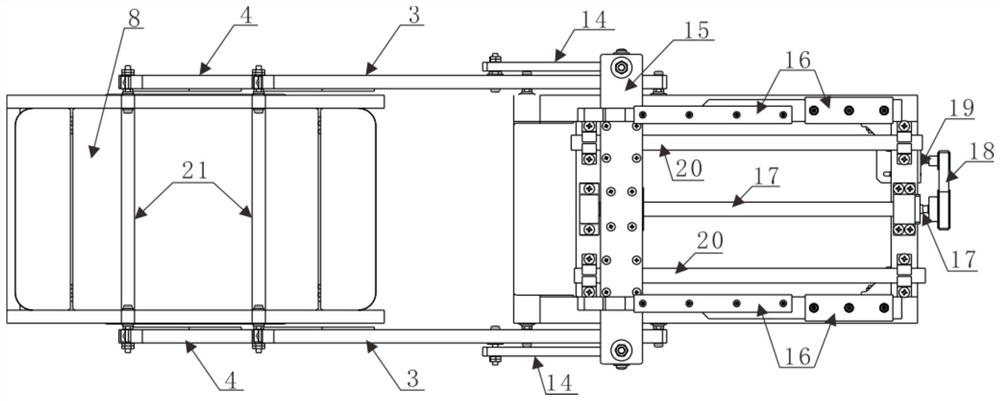

Automatic laser welding machine for edge grinding wheel

PendingCN114346426AEfficient arrangementRealize butt weldingLaser beam welding apparatusTool bitEngineering

The invention belongs to the technical field of edge grinding wheel production. An edge grinding wheel automatic laser welding machine comprises a machine frame, a base body storage frame, a vibration disc, a tool bit arranging and clamping device, an edge grinding wheel welding rotating device, a base body taking and placing device, a tool bit taking and placing device, a laser welding device and an edge grinding wheel discharging and conveying device, and the base body storage frame is used for storing a base body; a tool bit feeding device is arranged at an outlet of the vibration disc; the tool bit arranging and clamping device is used for clamping the tool bits pushed out by the tool bit feeding device and arranging the tool bits annularly at intervals. The edge grinding wheel welding rotating device is used for clamping the base body and driving the base body to rotate. The base body taking and placing device grabs a base body and feeds the base body to the edge grinding wheel welding rotating device. The tool bit taking and placing device is used for grabbing a whole tool bit and aligning the base body. The laser welding device is used for welding the tool bit and the base body. The base body can be automatically grabbed and fed, and tool bits can be effectively arranged and integrally clamped and transferred, so that the tool bits and the base body are integrally aligned and welded.

Owner:郑州金海威科技实业有限公司

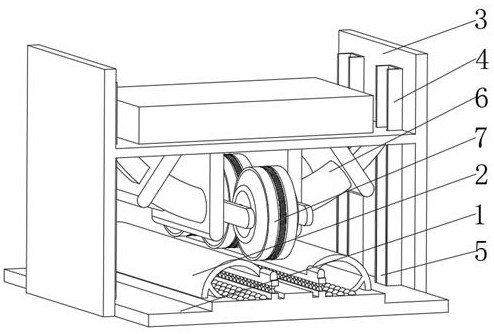

a double garage

InactiveCN109184291BMeet parking needsReduced fixed footprintParkingsElectric machineryStructural engineering

The invention discloses a double-deck garage, which comprises a first garage, a second garage and a controller. The first garage is equipped with a first motor and a linkage mechanism. The first motorcontrols the lifting and lowering of the second garage through the linkage mechanism, and the first motor is connected with the controller. The first garage of the invention is fixed on the ground. The second garage can be laid flat in front of the first garage or be overlapped on the upper end of the first garage under the drive of the first motor and the linkage mechanism, so as to meet the parking demand of the double-deck garage. Meanwhile, the space occupied by the second garage when the second garage is laid flat is a passage, and the second garage does not occupy the passage space whenput away, so that the fixed occupancy area of the double-deck garage is reduced, the installation difficulty is low, and a vehicle can quickly avoid other vehicles.

Owner:HENAN POLYTECHNIC UNIV

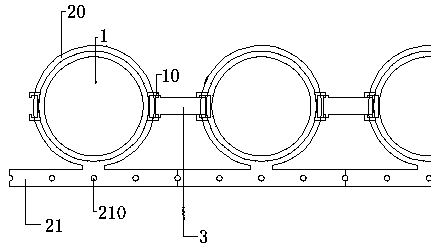

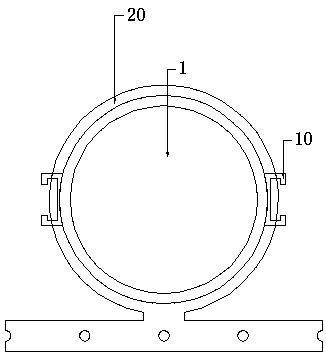

Prefabricated hollow tube device for hollow floor slab

The invention relates to a forming component of a hollow floor slab hole, in particular to a prefabricated hollow tube device for a hollow floor slab. The prefabricated hollow tube device for the hollow floor slab comprises hollow tubes, wherein the hollow tubes are placed in a longitudinal direction of the hollow floor slab, the interiors of the hollow tubes are hollow; connecting grooves are arranged at the two sides of the tube bodies, and the adjacent hollow tubes are connected by connecting devices matching with the connecting grooves. The prefabricated hollow tube device for the hollow floor slab provided by the invention has the following advantages: 1. The distance between the tubes of the prefabricated hollow tube group can be controlled according to the design requirements. 2. After being grouped by the connecting devices, the deviation of the hollow tubes caused by the vibration of a vibrating rod, the great or small distance between the adjacent hollow tubes can be avoidedwhen pouring the concrete. 3. The prefabricated hollow tube is conducive to realizing the flow prefabrication operation and improving the production efficiency. 4. The hollow floor slab can be pouredforced for once, and the hollow can be formed without pulling the core. 5. The anti-floating of the prefabricated hollow tube group can be achieved by penetrating a steel bar through the hole at the lower part of a sleeve tube.

Owner:江西联保工程咨询有限公司

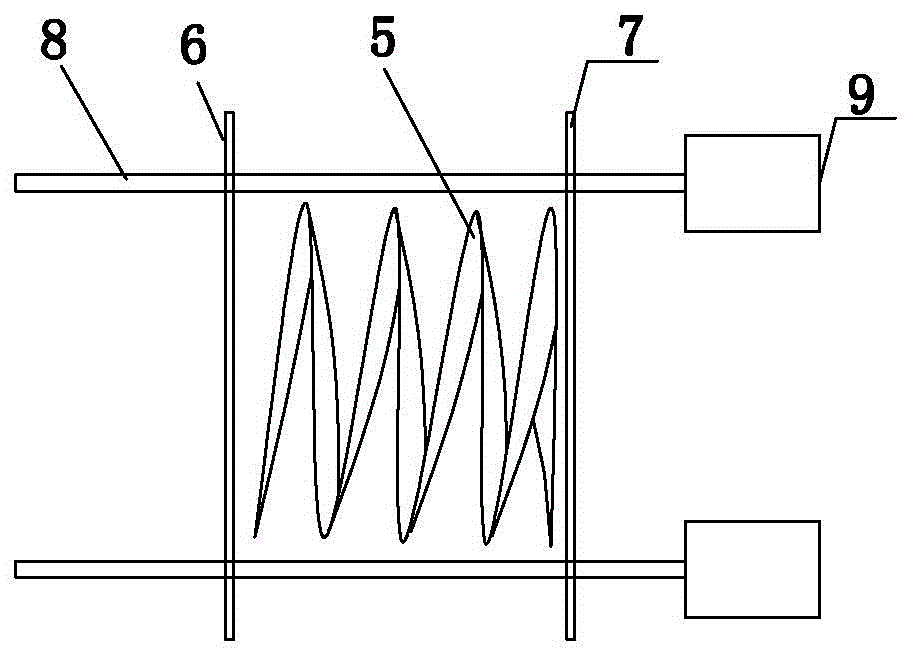

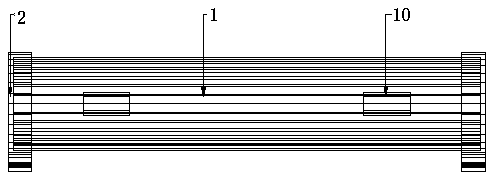

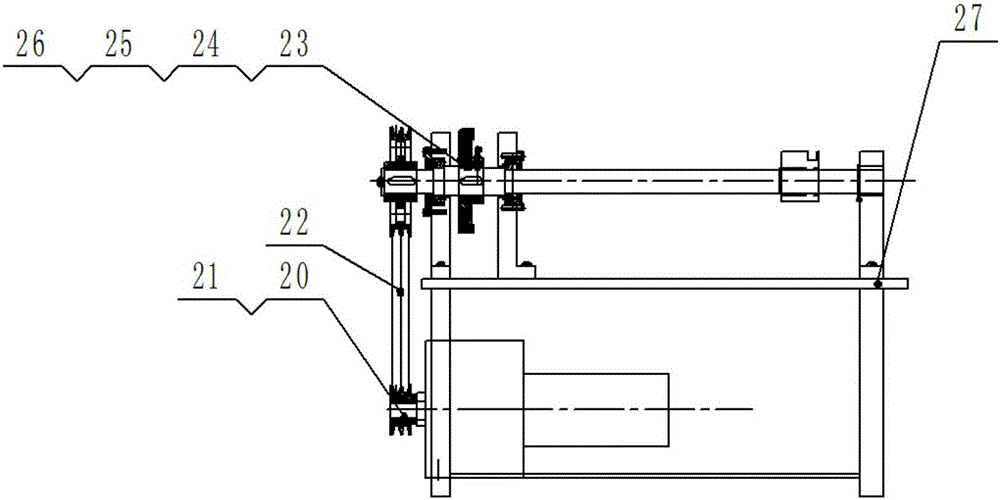

Metal part induction heating coil winding device

The invention discloses a metal part induction heating coil winding device which comprises a swing needle speed reducer, a main transmission shaft, a winding mandrel, a lead screw shaft and a fixing shaft, wherein the swing needle speed reducer is arranged below a work table of a machine tool, and the main transmission shaft, the winding mandrel, the lead screw shaft and the fixing shaft are arranged above the work table. The main transmission shaft is connected with the winding mandrel through a coupler, a driven belt pulley and a driving belt pulley are arranged on the main transmission shaft, the driving belt pulley is arranged on a speed reducer shaft of the swing needle speed reducer and connected with the driven belt pulley through a triangular belt, a driven gear meshed with a driving gear is arranged on the lead screw shaft, and a sliding rail is arranged between the lead screw shaft and the fixing shaft. The winding device has the advantages that the distance between coils wound by the winding device is effectively controlled and can keep consistent, the size of an outer ring can keep consistent, the distance between heating coil turns can be effectively controlled, the inner diameter and the outer diameter of coils of same specifications can be effectively controlled, heating coils are standardized, so that temperature stability of heating products is ensured, and product quality is improved.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com