A plastic film cutting device for convenient waste collection

A waste material and winding roller technology, which is applied in metal processing and other directions, can solve the problems that operators are not easy to clean up, waste materials are scattered on the ground, and affect work efficiency, etc., and achieve the effects of easy recycling, high accuracy and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

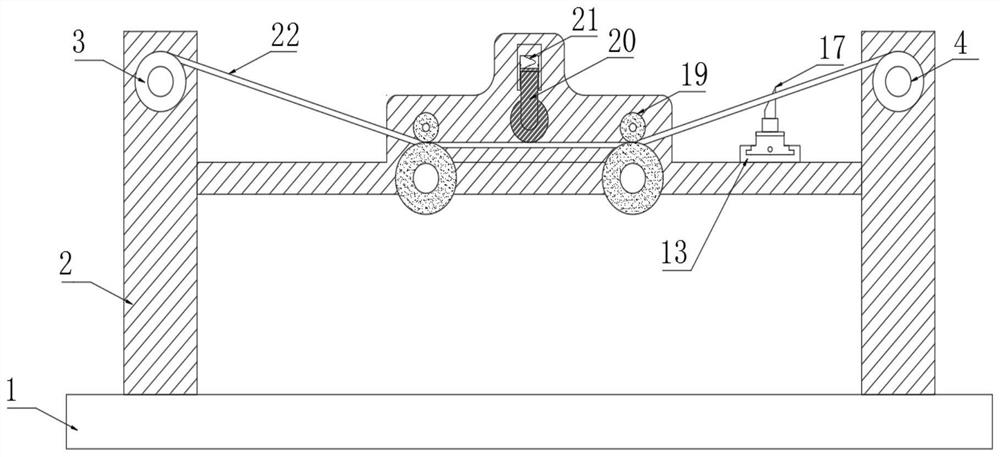

[0026]The present invention provides a plastic film tailition apparatus facilitating the waste, including a base 1, and the base 1 is configured with a column 2, and the column 2 is provided with a winding roller 3 and a winding roller 4, respectively;

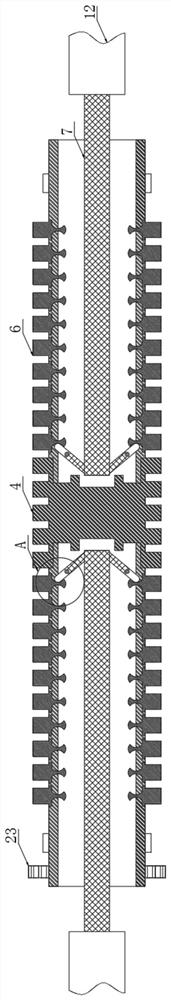

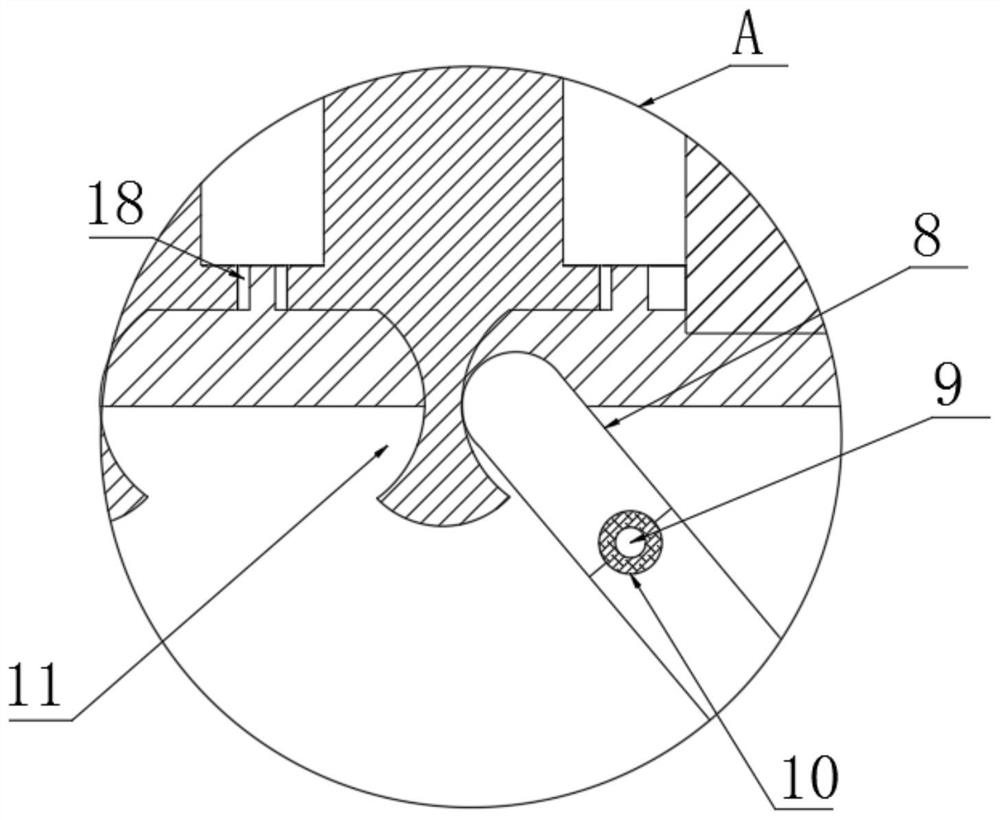

[0027]The shackle roller 3 and the winding roller 4 are connected to the column 2 through the bearing, the surface of the winding roller 4, is sorted by a slide 5, and the surface of the winding roller 4 is provided with a separation of the joint connection with the chute 5. Part 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com