Variable-distance multi-working-head manipulator

A technology of manipulators and work heads, applied in the field of manipulators, can solve problems such as low efficiency, and achieve the effect of improving production efficiency and saving loading and unloading time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

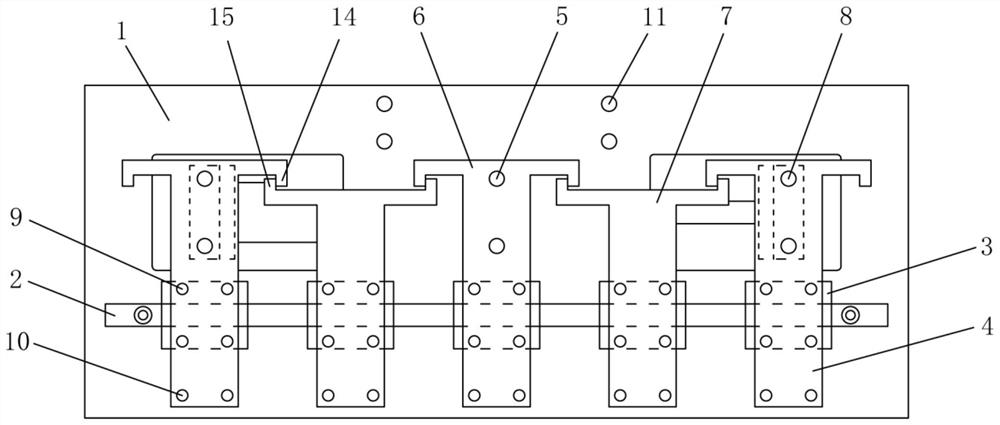

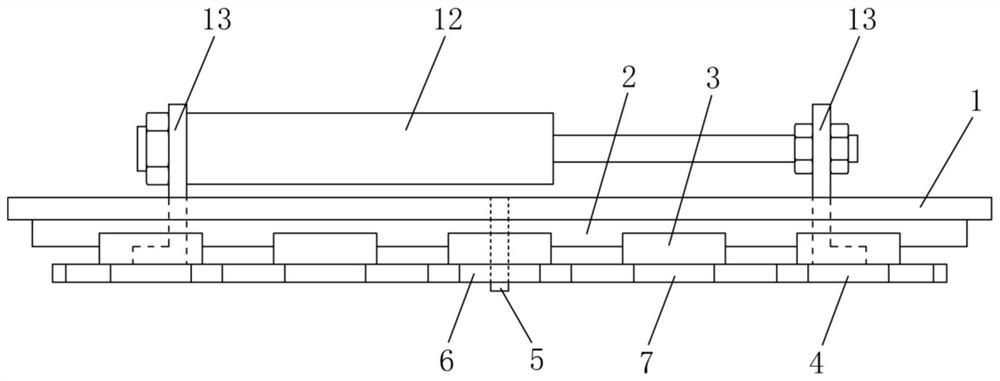

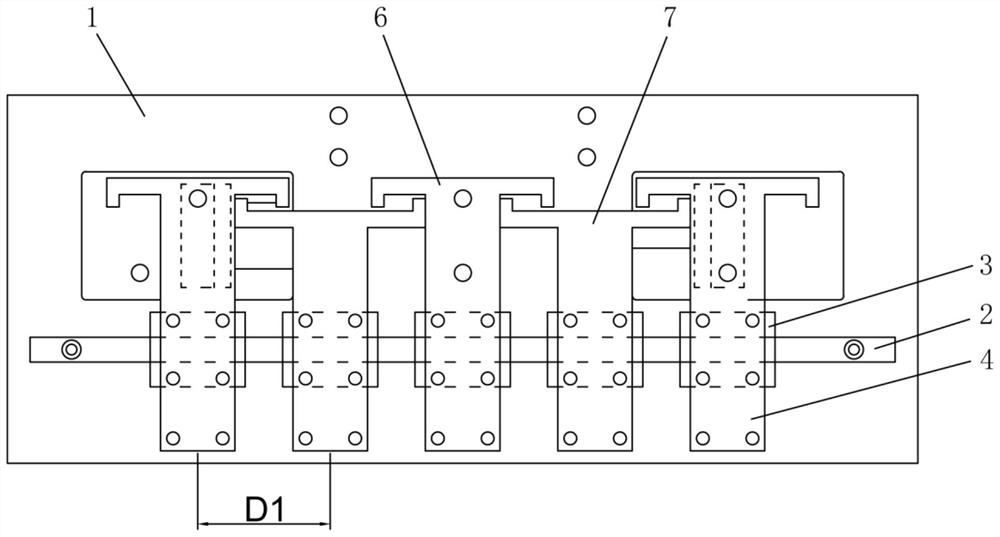

[0025] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as Figure 1 to Figure 4 As shown, a variable-pitch multi-head manipulator of the present invention includes a manipulator substrate 1 installed on a robot or a mobile module 20, and a plurality of manipulator substrates 1 for installing grabbing heads 16 are evenly spaced on the manipulator substrate 1. The limit piece unit and the driving assembly, the drive assembly drives a plurality of limit piece units to move with a variable pitch on the manipulator base plate 1 . The above constitutes the basic structure of the present invention.

[0027] The present invention adopts such a structure, installs the manipulator base plate 1 on the robot or the mobile module 20, and drives a plurality of limit pieces to move with a variable pitch on the base plate 1 through the drive assembly during operation, so as to realize the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com