Mask sheet making machine

A technology of mask and conveying mechanism, which is applied in the direction of winding strips, sending objects, and tools for sewing clothes. It can solve problems such as difficult spacing, uneven force, and shortened service life, so as to improve the efficiency of sheeting and the cutting surface. Smooth finish, compact structure, and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

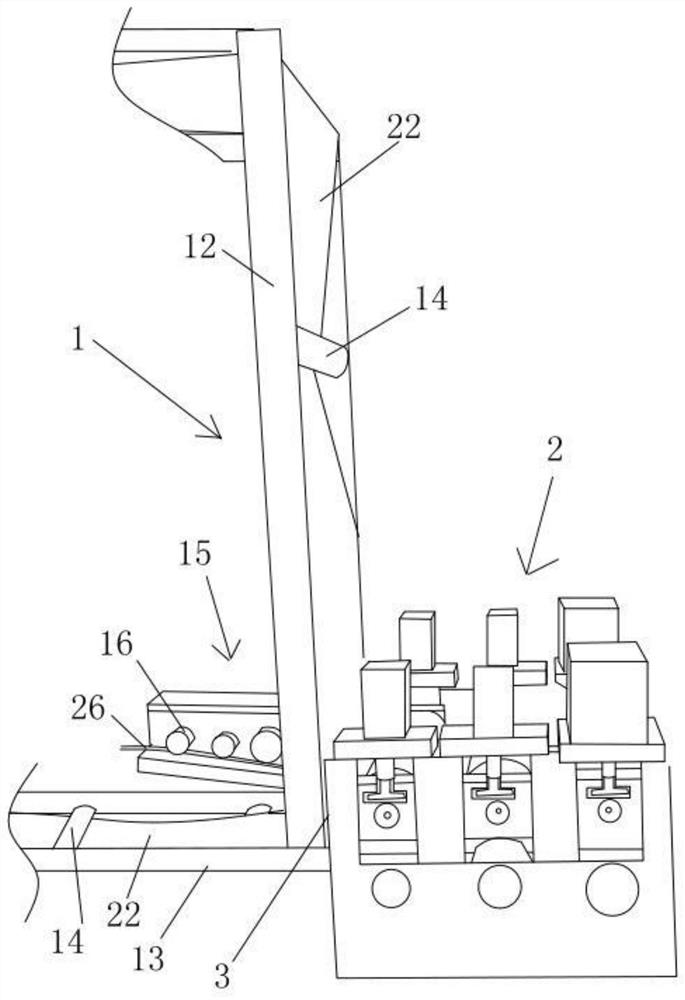

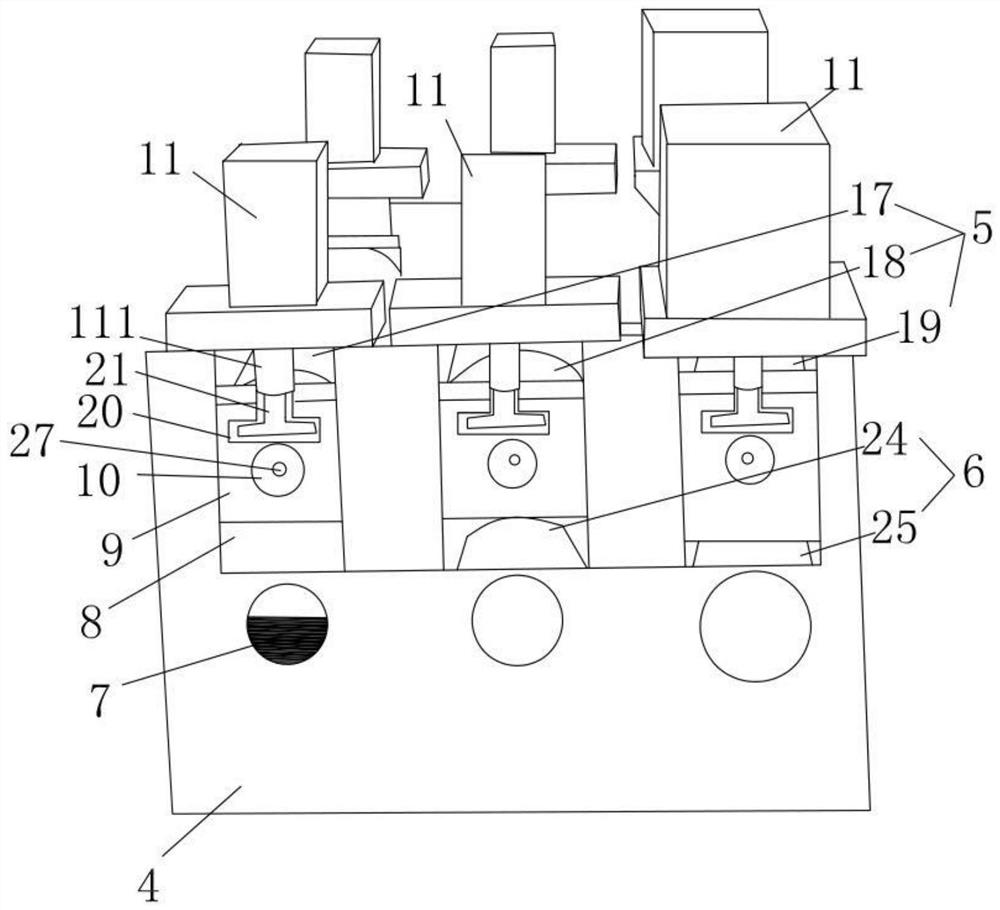

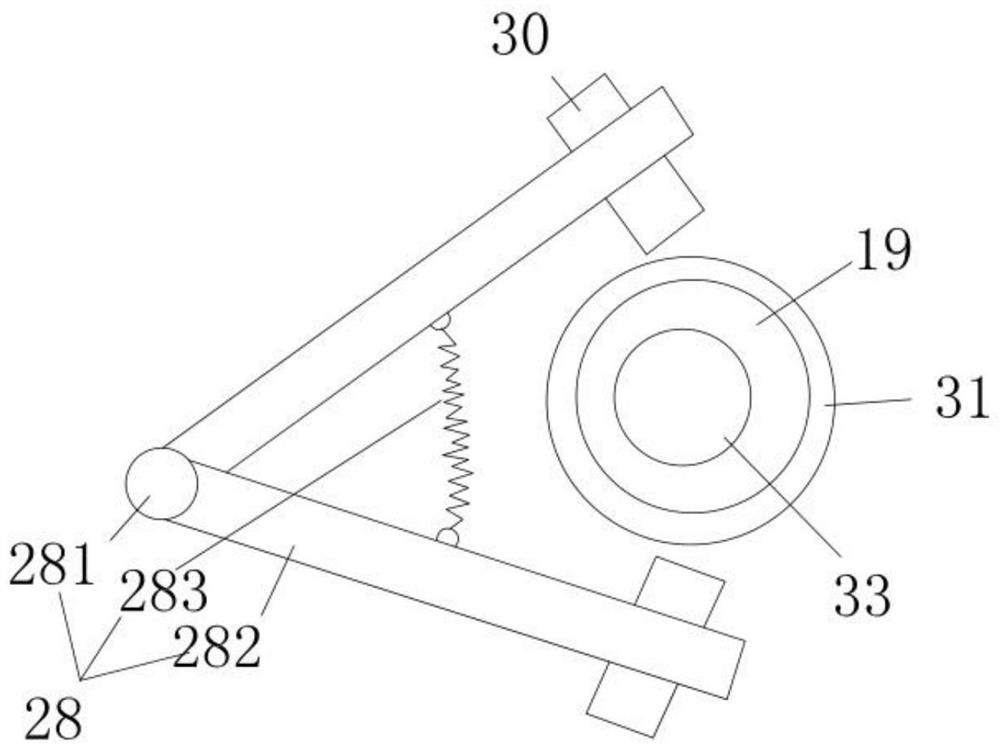

[0025] A kind of mask punching machine of the present embodiment, Figure 1-Figure 2 As shown, it includes a sheet material 22 conveying mechanism 1 and a sheet material die-cutting mechanism 2, the sheet material inlet end 3 of the conveying mechanism is connected to the die-cutting mechanism, and the conveying mechanism will input the gauze used to prepare the mask into the die-cutting mechanism , the die-cutting mechanism presses and cuts the sheet material 22; Just below the roller group 5, there is a pillow roller group 6 and an ultrasonic vibrator mold 7 for printing. The ultrasonic vibrator mold 7 emits ultrasonic waves and cooperates with the molding and cutting roller to play the role of molding and cutting. The cutting rollers cooperate, and the length direction of the two sleeper roller groups 6 is perpendicular to the conveying direction of the sheet material 22. The station frame 4 is provided with two symmetrical guide grooves 8, and each guide groove 8 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com