Production method of high-concentration water-soluble nitrophosphate fertilizer

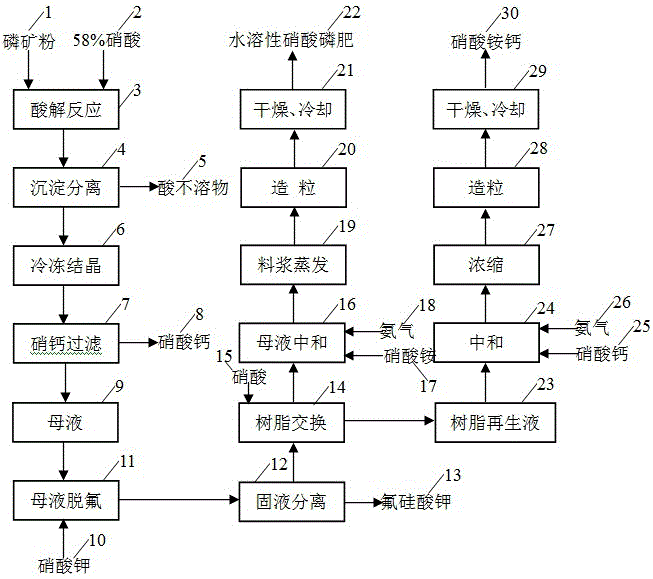

A production method, nitrophosphate fertilizer technology, applied in the direction of ammonium nitrate fertilizer, nitrate fertilizer, nitrogen fertilizer, etc., can solve the problems of ineffective utilization of re-production calcium sulfate, increased precipitation of magnesium, aluminum and iron, waste of resources, etc., to meet the needs of water and fertilizer integration , zero-emission resources, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The quality indicator of the phosphate rock 1 of the present embodiment: P 2 o 5 31.2%, CaO 44.4%, F 2.8%, AI 13.2%, Fe 2 (Al 2 O) 3 A total of 2.5%, other impurities; the concentration of nitric acid 2 was 58%.

[0026]Nitric acid 2 and phosphate rock 1 are added to the acidolysis tank according to the stoichiometric ratio of 1.2:1 for acidolysis reaction 3, the acid insoluble matter 5 in the acidolysis solution is separated by precipitation separation 4, and then the acid insoluble matter 5 is completely separated The acid solution is sent to the frozen crystallization 6, and the frozen crystal calcium nitrate 8 is separated from the acid solution and filtered into the calcium nitrate filter 7 for solid-liquid separation. The resulting liquid is the mother liquor 9, and then the mother liquor 9 is sent to the mother liquor defluorination tank 11 In the process, the mother liquor is defluorinated by adding potassium nitrate 10, and the fluorosilicate ions in the m...

Embodiment 2

[0028] The quality index of the phosphate rock 1 of the present embodiment is different from that of embodiment one, and the quality index is: P 2 o 5 32.5%, CaO 47%, F2.9%, AI 6.0%, Fe 2 (Al 2 O) 3 Total 2.2%, other impurities; concentration of nitric acid 2 was 58%.

[0029] Nitric acid 2 and phosphate rock 1 are added to the acidolysis tank according to the stoichiometric ratio of 1.2:1 for acidolysis reaction 3, the acid insoluble matter 5 in the acidolysis solution is separated by precipitation separation 4, and then the acid insoluble matter 5 is completely separated The acid solution is sent to the frozen crystallization 6, and the frozen crystal calcium nitrate 8 is separated from the acid solution and filtered into the calcium nitrate filter 7 for solid-liquid separation. The resulting liquid is the mother liquor 9, and then the mother liquor 9 is sent to the mother liquor defluorination tank 11 In the process, the mother liquor is defluorinated by adding potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com