Waste acid cooperative disposal process in domestic waste incineration fly ash resource refining process

A domestic waste incineration and co-processing technology, which is applied in special compound water treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of backward waste acid treatment technology, waste acid recovery and utilization, and high treatment cost problems, to achieve the effect of dual resource utilization, saving water and cost, and reducing the amount of water added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

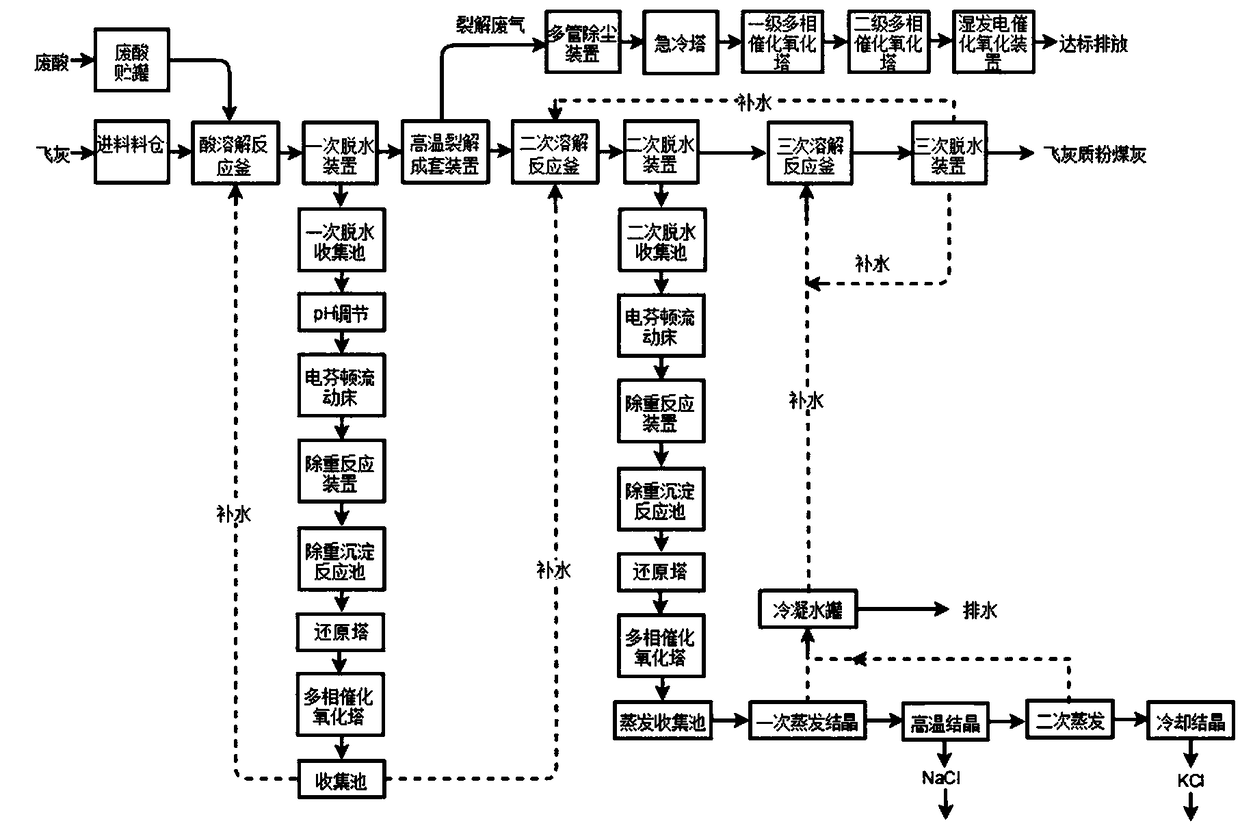

Method used

Image

Examples

Embodiment 1

[0040] (1) Add acid solution, water, solubilizer, flocculant and reducing agent to fly ash for dissolution and stirring, then add oxidant for secondary stirring, and finally separate solid and liquid. Calculated by mass when dissolving, add 1 part of fly ash to 2-3 parts of acid solution, and add 1-2 parts of water at the same time, the mass fraction of the acid solution is 10-20%; the stirring time for two times is 0.5h-2h; The acid used is industrial waste acids such as hydrochloric acid, nitric acid, sulfuric acid, etc., and the pH value of the acid solution is 0.5-2; the solubilizer is a kind of substance that is insoluble in water and easily soluble in dioxins, preferably dimethyl phosphate and dimethyl carbonate Any one of ester, dimethyl sulfate, and acetone, the addition amount is 1%-3% of the whole solution mass; the flocculant is aluminum chloride, the dosage is 0.5%-1.5% of the whole solution mass, and the reducing agent includes but not limited to For reducing subs...

Embodiment 2

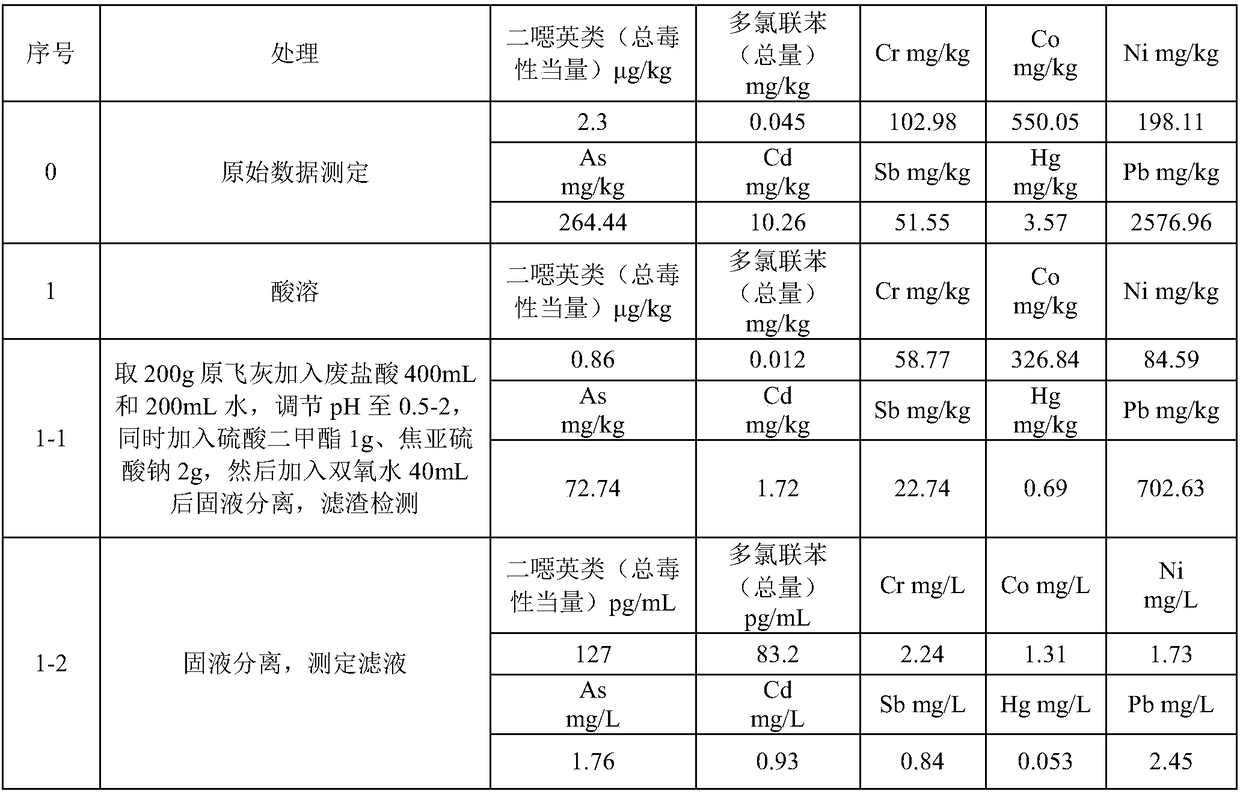

[0049] The fly ash in the experiment comes from a thermal power company in Shanghai. It is a typical fly ash produced by household waste incineration. It contains a lot of dioxins, heavy metals and salts, which is very harmful to the environment and human body. The waste acid comes from waste hydrochloric acid produced by a chemical plant, with a mass fraction of about 15%. The present invention can use waste acid to dissolve fly ash, and then remove heavy metals, dioxins and salts in fly ash through different processes, as shown in Table 1-1. And isolate the sodium chloride salt shown in Table 1-2 and the potassium chloride salt shown in Table 1-3.

[0050] Table 1-1 Experimental steps and experimental results

[0051]

[0052]

[0053] It can be seen from Table 1-1 that after dissolving the original fly ash, adjusting the pH value, adding a reducing agent, stirring for 1.5 hours, adding an oxidizing agent and continuing to stir for 1 hour, the dioxin-like toxic equiva...

Embodiment 3

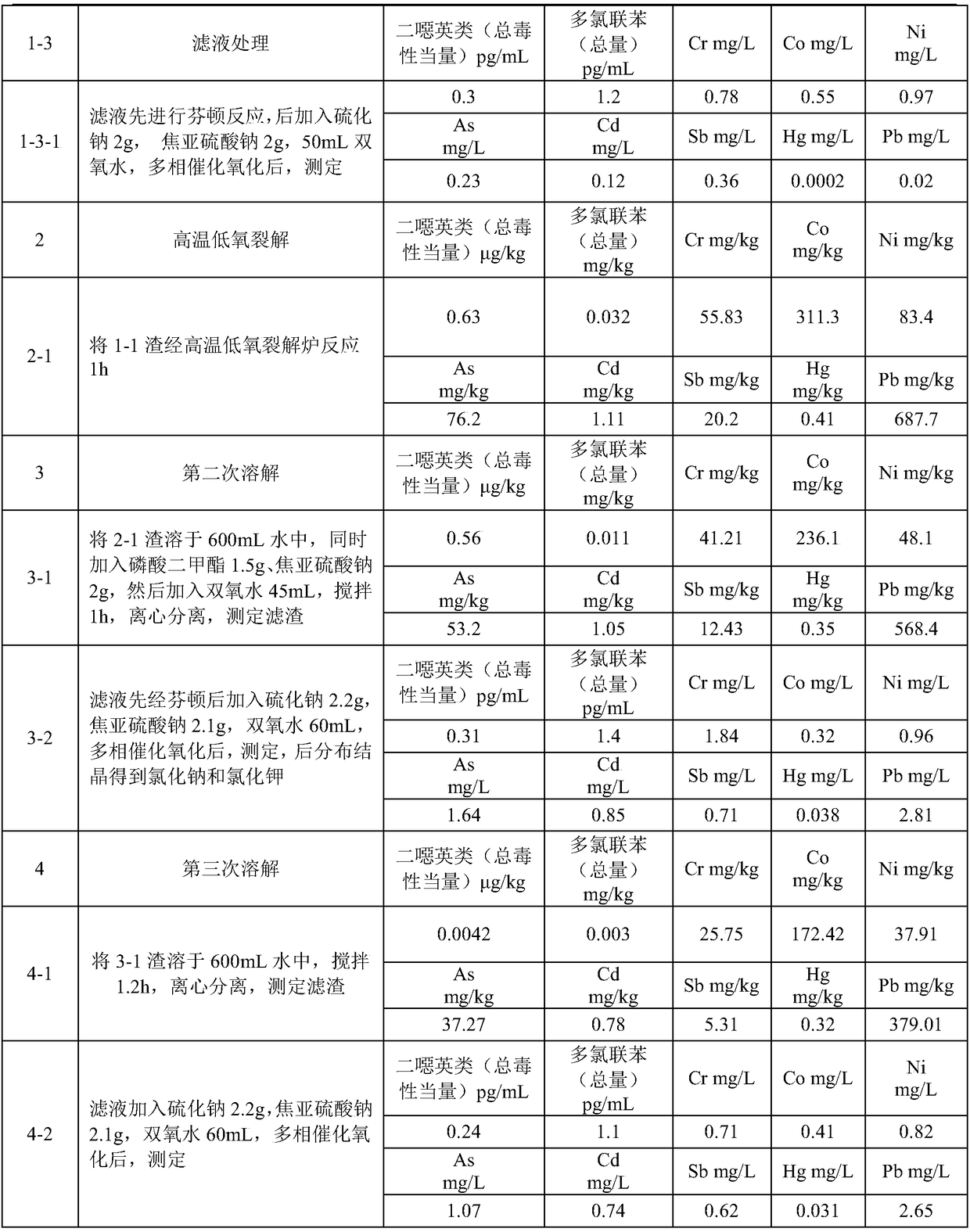

[0061] The fly ash in the experiment comes from a waste incineration plant in Jiangsu, which is a typical fly ash produced by the incineration of domestic waste. The content of dioxin, heavy metal and salt is very high, which is very harmful to the surrounding environment and human body. The waste acid comes from the waste sulfuric acid produced by a smelter dye factory, with a concentration of about 16%. The present invention can utilize waste acid to dissolve fly ash, and then remove heavy metals, dioxins and salts in fly ash through different processes, as shown in Table 2-1, and separate sodium chloride salt shown in Table 2-2 and chloride Potassium salts are shown in Table 2-3.

[0062] Table 2-1 Experimental steps and experimental results

[0063]

[0064]

[0065]

[0066] It can be seen from Table 2-1 that after dissolving the original fly ash, adjusting the pH value, adding a reducing agent, stirring for 1.8 hours, adding an oxidizing agent and continuing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com