Recycled wet-mixed mortar and preparation method thereof

A wet-mixed mortar and regenerated fine aggregate technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of increasing drying links, unfavorable energy saving and environmental protection, and large dust pollution, and achieve improvement The state of the mixture, the effect of great social significance and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

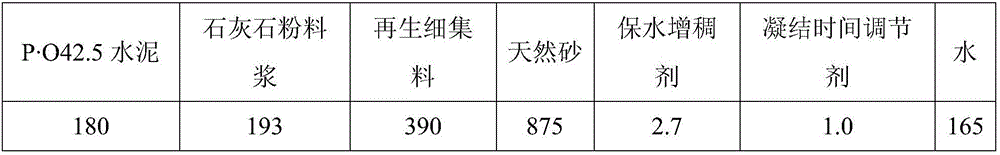

[0043] (1) Take a certain amount of raw materials by the mix ratio shown in Table 1:

[0044] Table 1 Mixing ratio of recycled wet-mixed mortar (unit: kg)

[0045]

[0046] (2) The weighed cement, limestone powder slurry, regenerated fine aggregate and natural sand are forced to stir in the mixer for 60s in advance, then add water-retaining thickener, setting time regulator and water, and continue to stir for 120s.

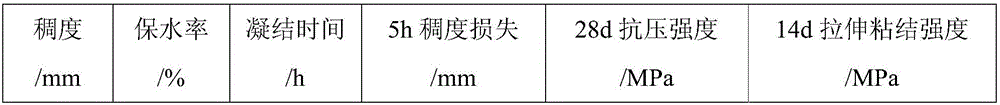

[0047] (3) Take a certain amount of wet-mixed mortar for the test, and test its performance indicators as shown in Table 2:

[0048] Table 2 Test results of performance indicators of wet-mixed mortar

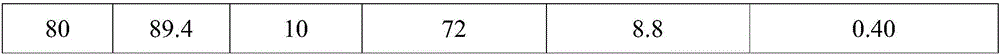

[0049]

[0050]

[0051] From the results shown in Table 2, it can be seen that the recycled wet-mixed mortar meets the requirements of M5 strength grade, and its performance indicators meet the requirements of various indicators for wet-mixed mortar in "Ready-mixed Mortar" GB / T25181-2010. Can be used for masonry and plastering.

Embodiment 2

[0053] (1) Take a certain amount of raw materials by the mix ratio shown in Table 3:

[0054] Table 3 Mixing ratio of recycled wet-mixed mortar (unit: kg)

[0055]

[0056] (2) The weighed cement, limestone powder slurry, regenerated fine aggregate and natural sand are pre-stirred in a mixer for 80s, then water-retaining thickener and setting time regulator water are added, and the forced stirring is continued for 150s.

[0057] (3) Take a certain amount of wet-mixed mortar for the test, and test its performance indicators as shown in Table 4:

[0058] Table 4 Test results of performance indicators of wet-mixed mortar

[0059]

[0060] From the results shown in Table 4, it can be seen that the recycled wet-mixed mortar meets the requirements of the M15 strength grade, and its performance indicators meet the requirements for wet-mixed mortar in the "Ready-mixed Mortar" GB / T25181-2010. Can be used for masonry and plastering.

Embodiment 3

[0062] (1) Take a certain amount of raw materials by the mix ratio shown in Table 5:

[0063] Table 5 Mixing ratio of recycled wet-mixed mortar (unit: kg)

[0064]

[0065] (2) The weighed cement, limestone powder slurry, regenerated fine aggregate and natural sand are forced to stir in the mixer for 60s in advance, then add water-retaining thickener, setting time regulator and water, and continue to stir for 120s.

[0066] (3) Take a certain amount of wet-mixed mortar for the test, and test its performance indicators as shown in Table 6:

[0067] Table 6 Test results of performance indicators of wet-mixed mortar

[0068]

[0069] From the results shown in Table 6, it can be seen that the recycled wet-mixed mortar meets the requirements of M10 strength grade, and its performance indicators meet the requirements of various indicators for wet-mixed mortar in "Ready-mixed Mortar" GB / T25181-2010. Can be used for masonry and plastering.

[0070] Those of ordinary skill in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com