Method for recycling solar energy crystalline silicon cutting waste size

A waste slurry, crystalline silicon technology, applied in recycling technology, plastic recycling, liquid fertilizer and other directions, can solve problems such as lack of competitiveness, achieve great economic value and social significance, sufficient reserves, and improve fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

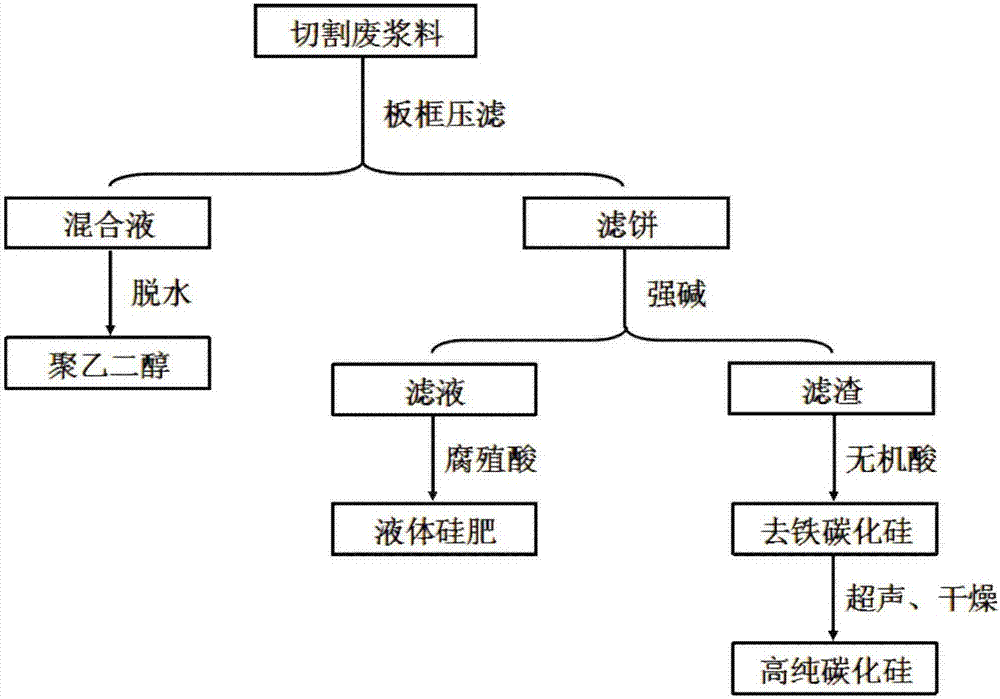

[0033] A method for recycling solar crystalline silicon cutting waste slurry, comprising the following specific steps:

[0034] S1. Put 100L monocrystalline silicon cutting waste slurry into a plate and frame filter press for physical pressure filtration, and collect the primary filtrate and primary filter residue respectively;

[0035] S2, obtain the primary filtrate containing the polyethylene glycol / water mixture, heat it, and obtain about 40 kg of polyethylene glycol after evaporating the water;

[0036] S3, dissolving the primary filter residue in water, adding 50 kg of potassium hydroxide, heating and stirring until the reaction is complete, and then carrying out physical secondary filtration, collecting the secondary filtrate and the secondary filter residue respectively;

[0037] S4, obtain the secondary filtrate containing potassium silicate, add humic acid 35kg in the secondary filtrate, and the pH value is adjusted to 8, then the secondary filtrate is evaporated and...

Embodiment 2

[0041] A method for recycling solar crystalline silicon cutting waste slurry, comprising the following specific steps:

[0042] S1. Put 100L polysilicon cutting waste slurry into a plate and frame filter press for physical pressure filtration, and collect the primary filtrate and primary filter residue respectively;

[0043] S2, obtain the primary filtrate containing the polyethylene glycol / water mixture, heat it, and obtain about 40 kg of polyethylene glycol after evaporating the water;

[0044]S3, dissolving the primary filter residue in water, adding 60 kg of potassium hydroxide, heating and stirring until the reaction is complete, and then carrying out physical secondary filtration, collecting the secondary filtrate and the secondary filter residue respectively;

[0045] S4, obtain the secondary filtrate containing potassium silicate, add humic acid 25kg in the secondary filtrate, and the pH value is adjusted to 10, then the secondary filtrate is evaporated and concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com