SiBCN composite material and preparation method thereof

A composite material and silicon boron carbon nitride technology, which is applied in the field of preparation of silicon boron carbon nitrogen composite materials, can solve the problems of poor uniformity of composite materials, high energy consumption and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of polyborosilazane: use ammonia as nitrogen source to ammonolyze methylvinyl dichlorosilane to form polysilazane, and then use dimethyl sulfide borane as boron source to borohydropolysilazane to obtain polyborosilazane Alkanes (synthesis of polyborosilazane by hydroboration reaction and preparation of SiBCN ceramics by hot pressing-pyrolysis. Journal of Silicates, 38, 1533-37, 2010).

[0042] Preparation of silicon-boron-carbon-nitrogen-based composite materials: 40kg polyborosilazane and 150kg cyclohexane were placed in a reactor, and then argon or nitrogen was flushed into the reactor as a protective gas, and then 60kg of liquid-phase SiCl 4 Add it into the reaction kettle, the temperature in the reaction kettle is 300° C., and the reaction time is 4 hours to obtain a mixture of polyborosilazane.

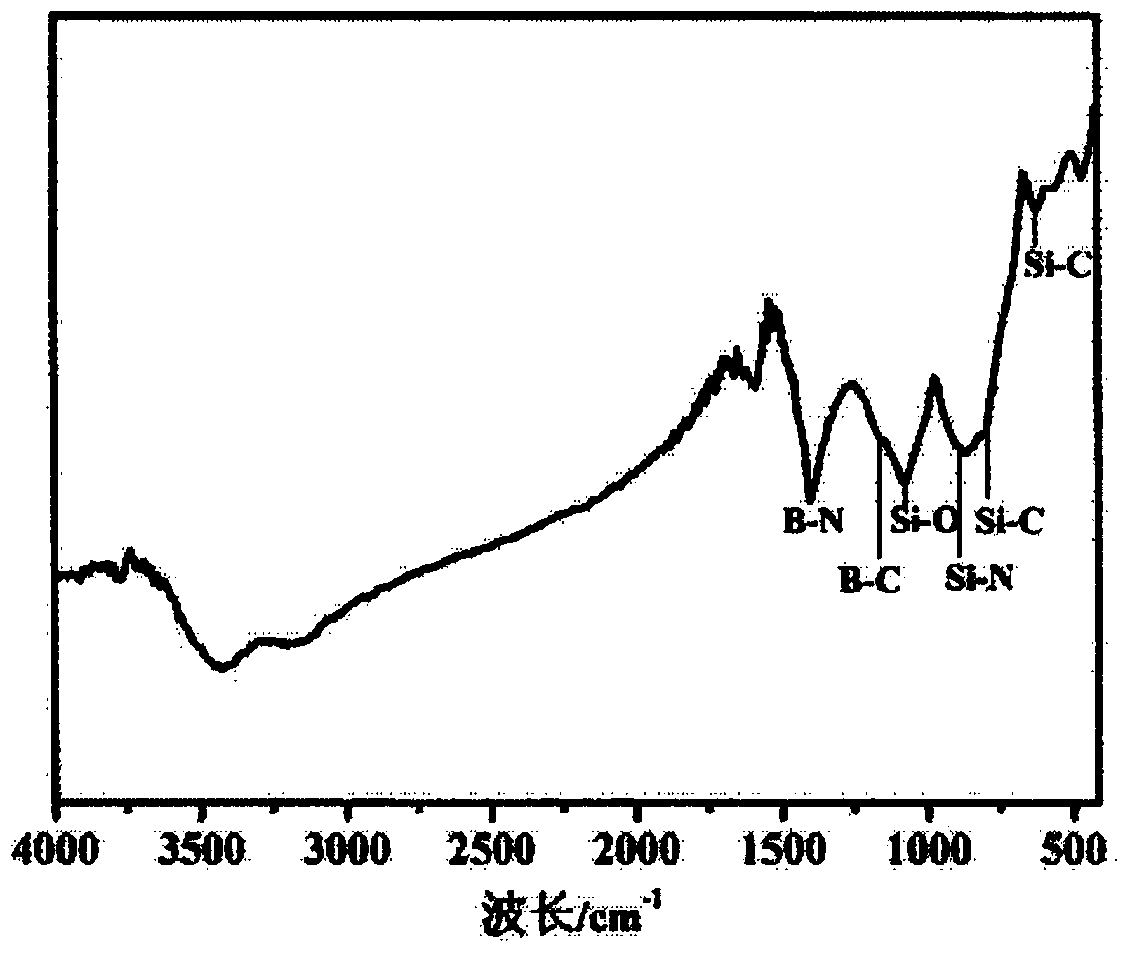

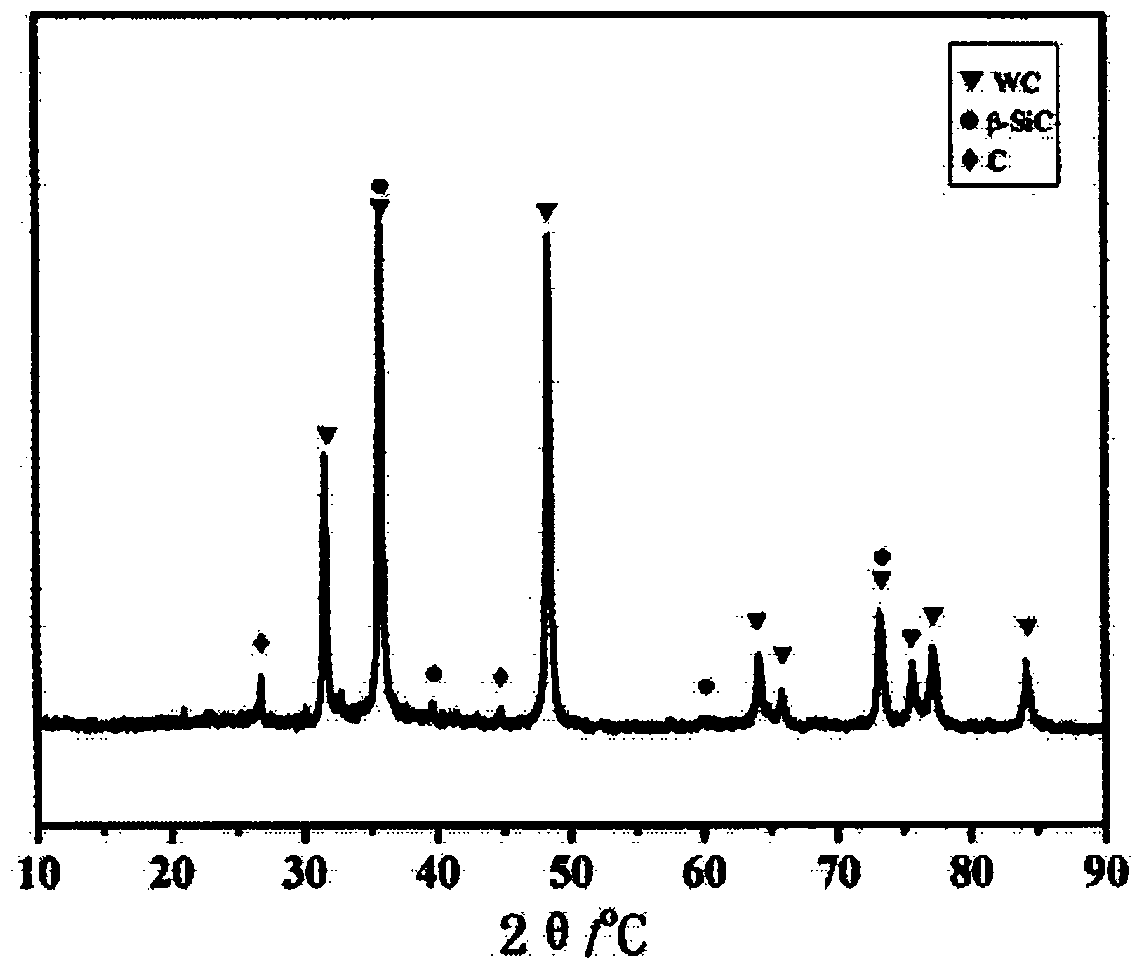

[0043] Under an inert or active atmosphere, heat the mixture of polyborosilazane and react at a rate of 10°C / min to 1300°C for 1 hour to prepare a silicon-boro...

Embodiment 2

[0046] Preparation of polyborosilazane: use ammonia as nitrogen source to ammonolyze methylvinyl dichlorosilane to form polysilazane, and then use dimethyl sulfide borane as boron source to borohydropolysilazane to obtain polyborosilazane Alkanes (synthesis of polyborosilazane by hydroboration reaction and preparation of SiBCN ceramics by hot pressing-pyrolysis. Journal of Silicates, 38, 1533-37, 2010).

[0047] Preparation of silicon-boron-carbon-nitrogen-based composite materials: 20kg of polyborosilazane and 60kg of n-hexane were placed in the reactor, and then argon or nitrogen was flushed into the reactor as a protective gas, and then 10kg of liquid-phase SiCl 4 Add it into the reaction kettle, the temperature in the reaction kettle is 100° C., and the reaction time is 12 hours to obtain a mixture of polyborosilazane.

[0048] Under an inert or active atmosphere, heat the mixture of polyborosilazane and raise the temperature to 800° C. at a rate of 20° C. / min for 6 hours ...

Embodiment 3

[0051] Preparation of polyborosilazane: use ammonia as nitrogen source to ammonolyze methylvinyl dichlorosilane to form polysilazane, and then use dimethyl sulfide borane as boron source to borohydropolysilazane to obtain polyborosilazane Alkanes (synthesis of polyborosilazane by hydroboration reaction and preparation of SiBCN ceramics by hot pressing-pyrolysis. Journal of Silicates, 38, 1533-37, 2010).

[0052] Preparation of silicon-boron-carbon-nitrogen-based composite materials: 30kg of polyborosilazane and 100kg of cyclohexane were placed in a reactor, and then argon or nitrogen was flushed into the reactor as a protective gas, and then 45kg of liquid-phase SiCl 4 Add it into the reaction kettle, the temperature in the reaction kettle is 200° C., and the reaction time is 8 hours to obtain a mixture of polyborosilazane.

[0053] Under an inert or active atmosphere, heat the mixture of polyborosilazane to 1000°C at a rate of 1°C / min to react for 4 hours to prepare a silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com