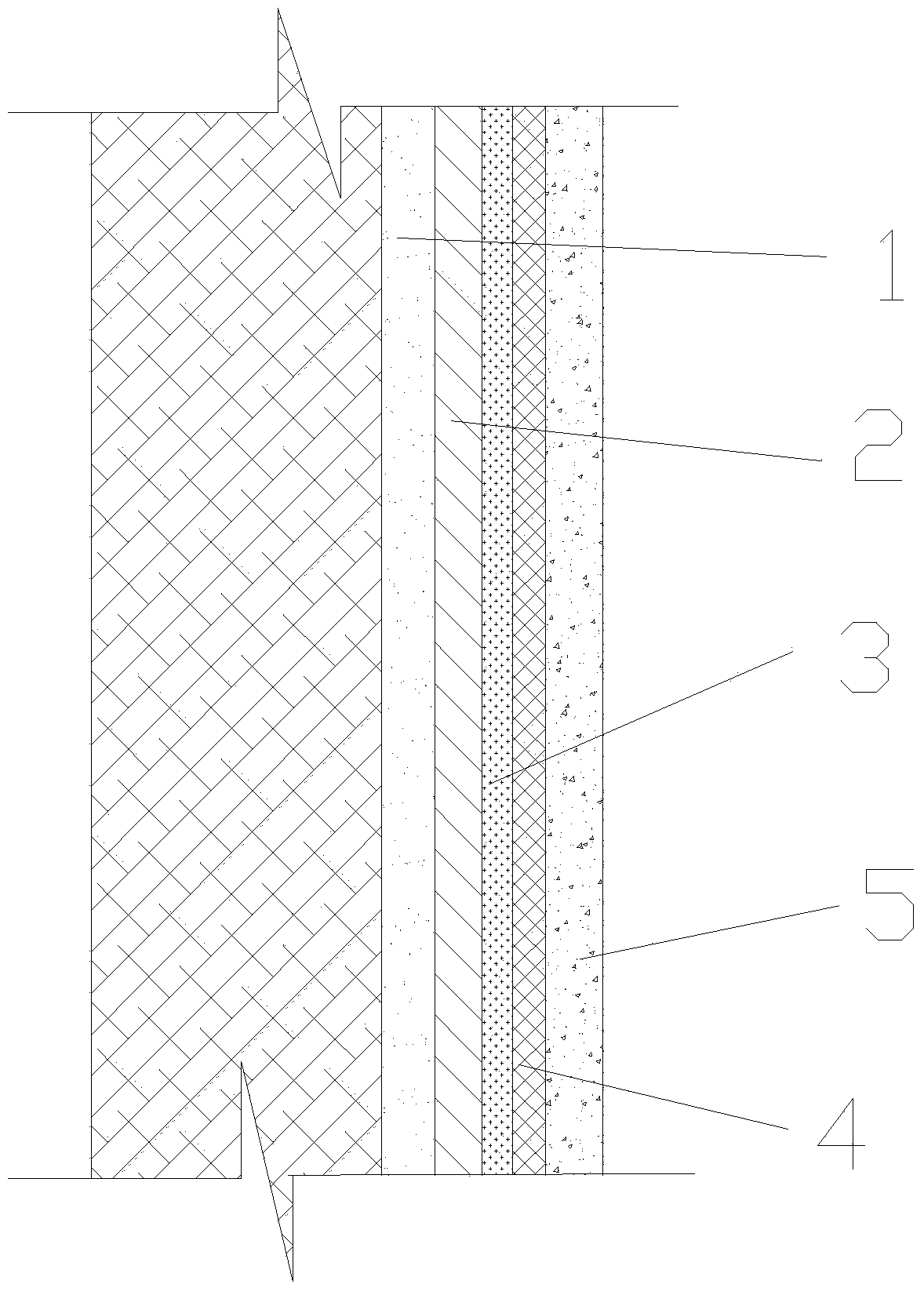

Outer wall waterproof structure

A waterproof structure and exterior wall technology, which is applied in building components, building insulation materials, etc., can solve problems such as inconvenience, and achieve the effects of simple operation, long service life and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Described component A comprises the pure acrylic high elastic emulsion of 100 parts by weight, the dispersant of 1.0 parts by weight, the defoamer of 0.8 parts by weight, the antioxidant of 1.0 parts by weight, the anti-ultraviolet absorber of 0.7 parts by weight and 0.15 parts by weight The thickener of part, described component B comprises the white portland cement of 65 parts by weight, the ground calcium carbonate of 15 parts by weight, the quartz sand of 20 parts by weight and the water reducer of 1.2 parts by weight.

Embodiment 2

[0036] Described component A comprises the pure acrylic high elastic emulsion of 95 parts by weight, the dispersant of 1.2 parts by weight, the defoamer of 0.75 parts by weight, the antioxidant of 1.1 parts by weight, the anti-ultraviolet absorber of 0.75 parts by weight and 0.13 parts by weight The thickening agent of part, described component B comprises the white Portland cement of 68 parts by weight, the ground calcium carbonate of 16 parts by weight, the quartz sand of 18 parts by weight and the water reducer of 1.1 parts by weight.

[0037]The pure acrylic high elastic emulsion is preferably GT166, the dispersant is preferably A10, the antioxidant is preferably 44PD, the ultraviolet absorber is preferably UV-P, and the thickener is preferably For hydroxyethyl cellulose. The strength of the Portland cement is preferably 42.5R, the preferred particle size of the ground calcium carbonate is 600 mesh, the particle size of the quartz sand is preferably 80-140 mesh, and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com