Foamed plastic for low-density and high-flame-retardant continuous slab and preparation method for foamed plastic

A foam plastic and high flame-retardant technology, which is applied in the field of low-density high flame-retardant continuous board foam plastic and its preparation, can solve the problems of insufficient reaction of raw materials, high injection density, low foam strength, etc., and achieve low production cost , simple process, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

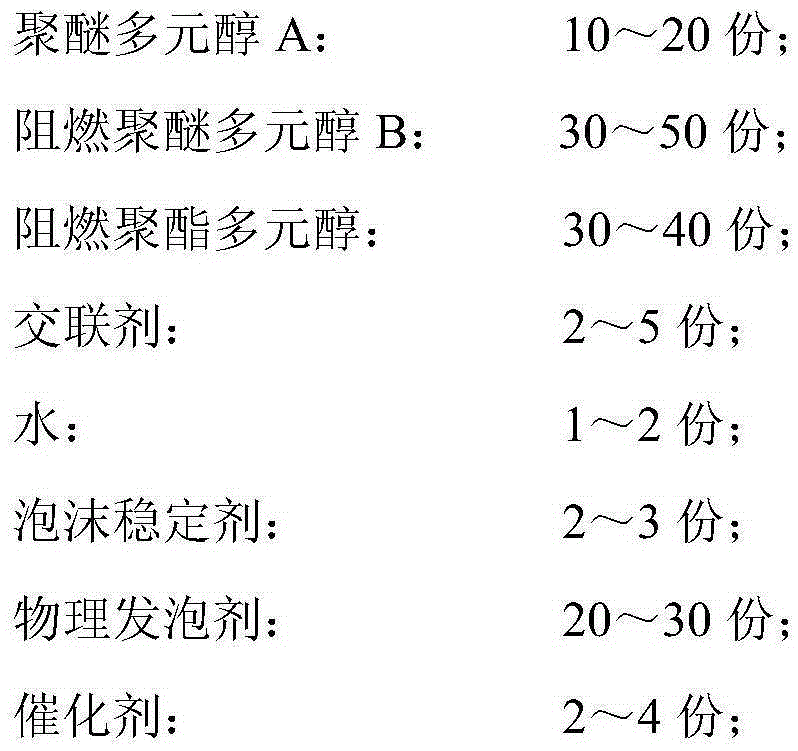

Method used

Image

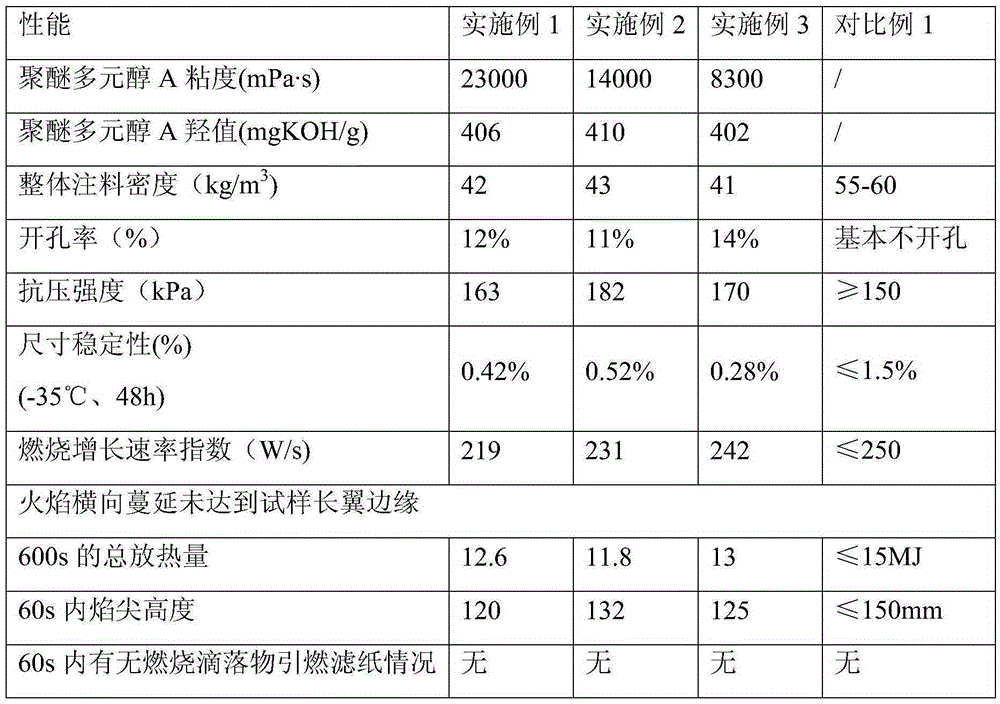

Examples

Embodiment 1

[0038] Preparation of polyether polyol A:

[0039] In a 2.5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 39.5g of pentaerythritol, 3.81g of catalyst KOH, and replace with nitrogen 5 times, and evacuated to a pressure of -0.08MPa, then stirred (speed 500r / min) to raise the temperature, when the temperature increased to 85°C, add 88.75g of ethylene oxide, control the initial pressure of 0.20MPa, and react until the pressure is constant , then the temperature was raised to 100°C, the pressure was controlled at 0.20MPa, 399.375g of propylene oxide was continuously added, and the remaining 177.5g of ethylene oxide was continuously added after the reaction until the pressure did not change. After a period of aging, the remaining 221.875g of propylene oxide was added Propylene oxide is added continuously, the pressure is controlled at 0.20MP...

Embodiment 2

[0058] Preparation of polyether polyol A:

[0059] In a 2.5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 39.5g of pentaerythritol, 3.81g of catalyst KOH, and replace with nitrogen 5 times, and evacuate to a pressure of -0.08MPa, then stir (speed 500r / min) to raise the temperature, when the temperature increases to 90°C, add 133.125g of ethylene oxide, control the initial pressure of 0.25MPa, and react until the pressure is constant , then the temperature was raised to 110°C, the pressure was controlled at 0.25MPa, 257.375g of propylene oxide was continuously added, and the remaining 337.25g of ethylene oxide was continuously added after the reaction until the pressure no longer changed, and the remaining 159.75g of ethylene oxide was added continuously after aging for a period of time. Add propane continuously, control the pressure at...

Embodiment 3

[0078] Preparation of polyether polyol A:

[0079] In a 2.5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342g of sucrose, 39.5g of pentaerythritol, 3.81g of catalyst KOH, and replace with nitrogen 5 times, and evacuated to a pressure of -0.08MPa, then stirred (speed 500r / min) to raise the temperature, when the temperature increased to 85°C, add 177.5g of ethylene oxide, control the initial pressure of 0.20MPa, and react until the pressure is constant , then the temperature was raised to 120°C, the pressure was controlled at 0.20MPa, 133.125g of propylene oxide was continuously added, and the remaining 488.125g of ethylene oxide was continuously added after the reaction until the pressure did not change. After a period of aging, the remaining 88.75g of epoxy Add propane continuously, control the pressure at 0.20MPa, react until the pressure no longer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com