Post heat treatment method for laser additive manufacturing 12CrNi2 alloy steel

A laser additive and post-heat treatment technology, applied in the direction of process efficiency improvement, energy efficiency improvement, etc., can solve the problems of low alloy strength, uneven structure, difficult to eliminate residual stress, etc., and achieve high strength, fine structure and grain size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

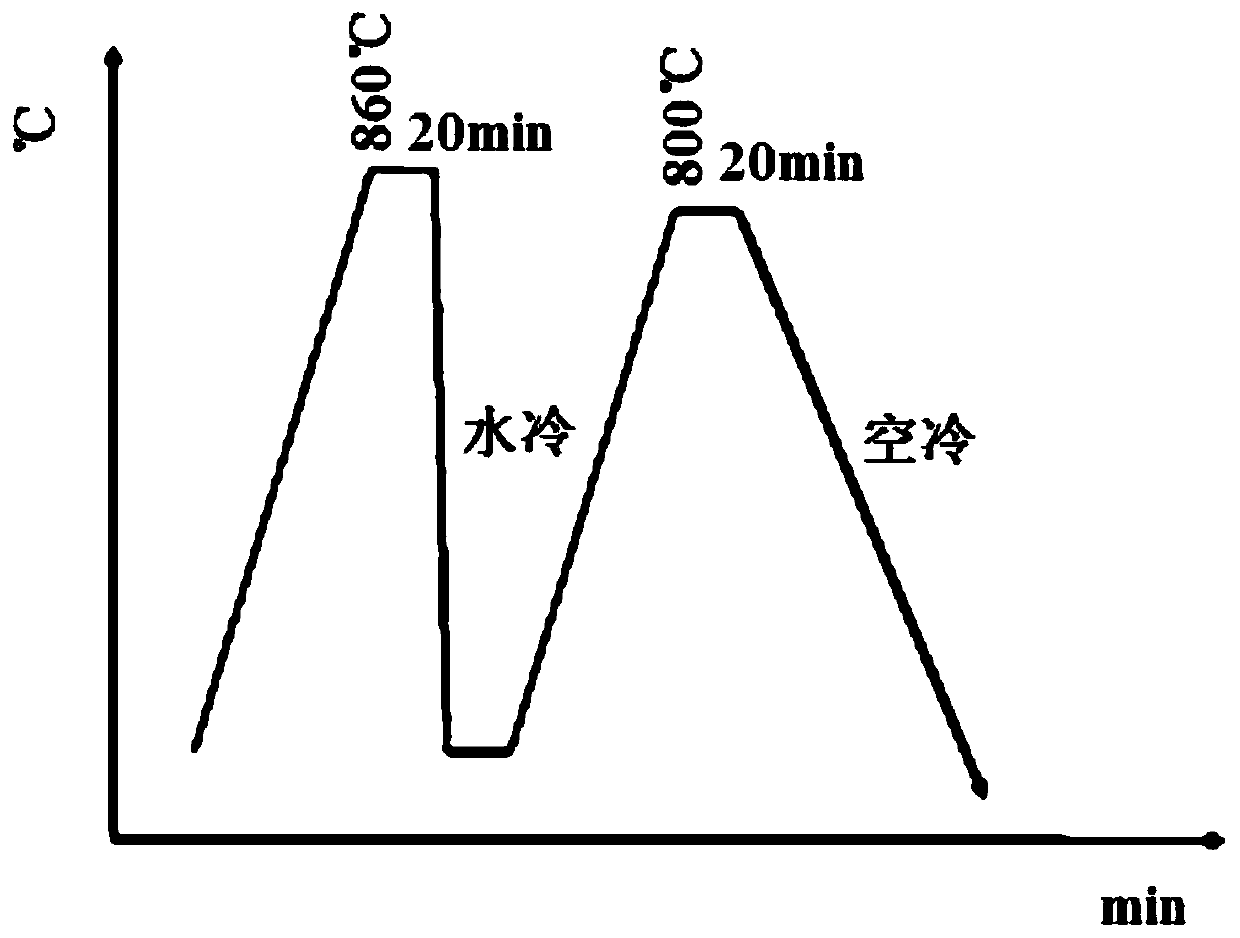

[0038] Specific embodiment one: This embodiment is a post-heat treatment method for laser additive manufacturing of 12CrNi2 alloy steel, which is specifically completed according to the following steps:

[0039] 1. Heating and heating: use cladding deposition materials to manufacture 12CrNi2 alloy steel, and then heat the 12CrNi2 alloy steel to 856 ° C ~ 866 ° C;

[0040] 2. Heat preservation: heat-preserve the heated 12CrNi2 alloy steel at 856°C to 866°C;

[0041] 3. Cooling: Cool the 12CrNi2 alloy steel after heat preservation to room temperature;

[0042] 4. Sub-temperature quenching: heating the cooled 12CrNi2 alloy steel to 734°C to 836°C and performing heat preservation treatment under this temperature condition, and then water cooling to room temperature to obtain the treated 12CrNi2 alloy steel.

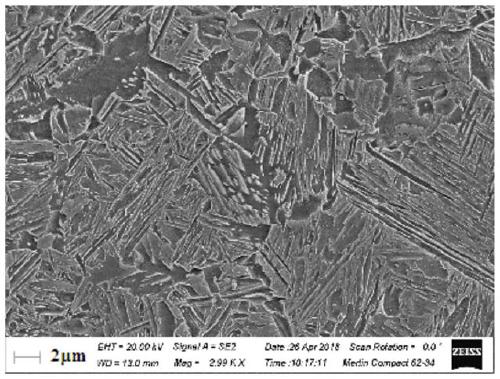

[0043] The principle of this implementation mode:

[0044] The post-heat treatment method for 12CrNi2 alloy steel manufactured by laser additive manufacturing is: quenching...

specific Embodiment approach 2

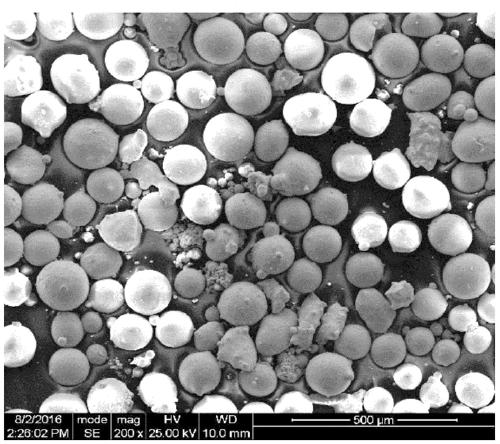

[0051] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the cladding deposition material described in step one is 12CrNi2 powder, and the chemical composition of 12CrNi2 powder is C: 0.08%~0.19%, Cr :

[0052] 0.7%~1%, Ni: 1.4%~2.1%, Mn: 0.2%~0.7%, Si: 0.14%~0.39%, the balance is Fe, and the oxygen concentration in 12CrNi2 powder is 260ppm~290ppm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the 12CrNi2 alloy steel manufactured by cladding deposition materials in step 1 is manufactured by laser additive manufacturing. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com