Niobium microalloyed HRB400E hot-rolled ribbed steel bar and efficient manufacturing method thereof

A hot-rolled ribbed steel bar and micro-alloying technology, which is applied in the field of iron and steel metallurgy, can solve the problems of low production efficiency and achieve the effect of low bainite content, high efficiency and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0094] A high-efficiency manufacturing method for niobium microalloyed HRB400E hot-rolled ribbed steel bar is provided, and the specific production process is as follows:

[0095] 130t converter smelting—argon station bottom blowing treatment or LF furnace refining—8 machines and 8 streams 170×170mm square billet continuous casting—slab heating—continuous bar mill rolling—upper cooling bed cooling—shearing—cutting to length—stretching bundle.

[0096] The steel billets are respectively rolled in three continuous bar mill production lines into steel bars with a diameter of 12-25mm.

[0097] Smelted in a 130t converter, nitrogen is blown at the bottom during the blowing process, manganese-silicon alloy, ferrosilicon, and ferroniobium are added in the tapping process of the converter for alloying, after tapping, the bottom blowing gas of the ladle is uniform, the composition and temperature of molten steel are fine-tuned, or LF furnace is used for refining treatment.

[0098] Th...

experiment example 1

[0111] The mechanical properties of steel bars are tested by the GB / 1499.2-2018 standard.

[0112] The results are shown in the table below:

[0113] Table 3 Mechanical properties and bainite content of steel bars in Examples 1-9 and Comparative Examples 1-6

[0114]

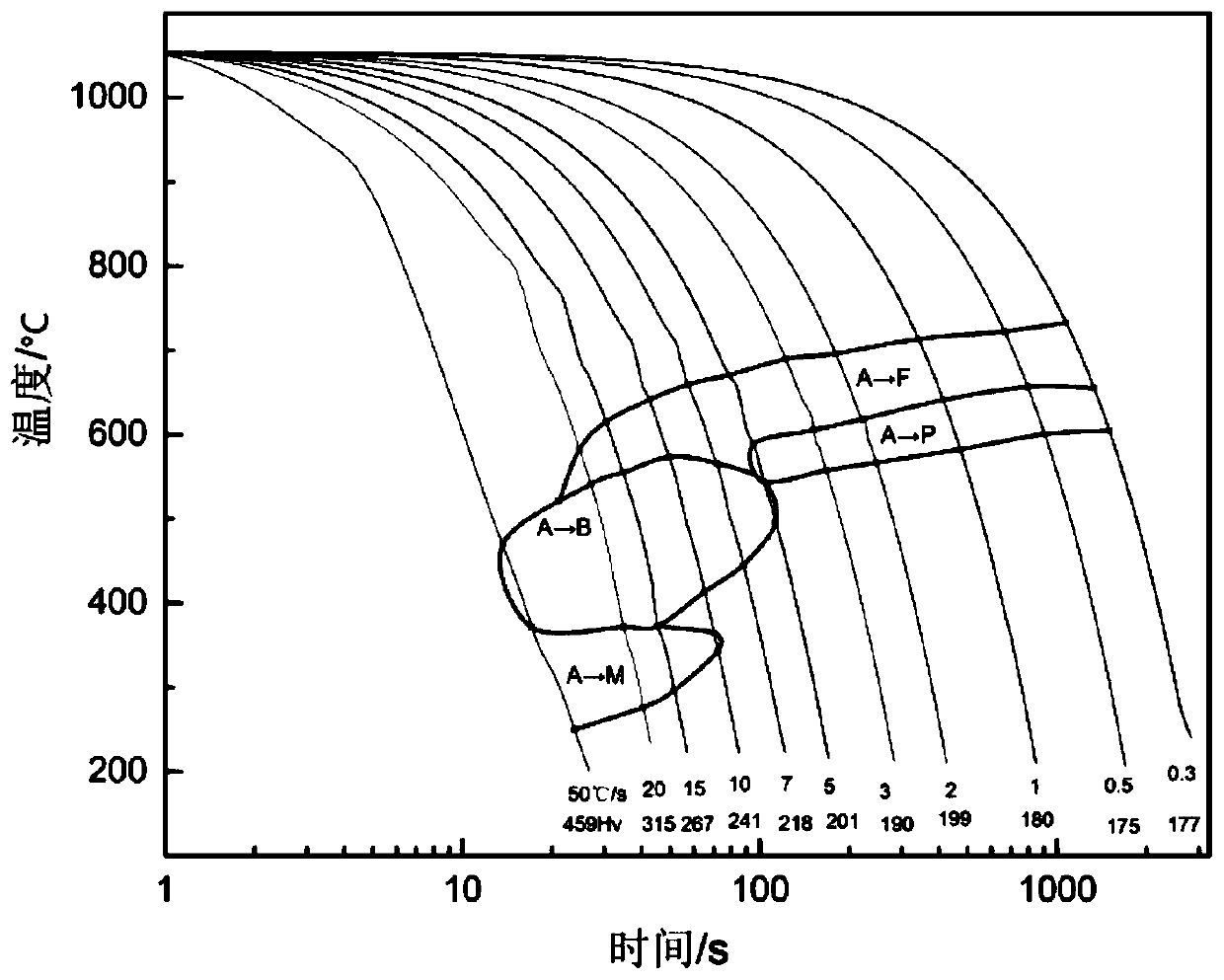

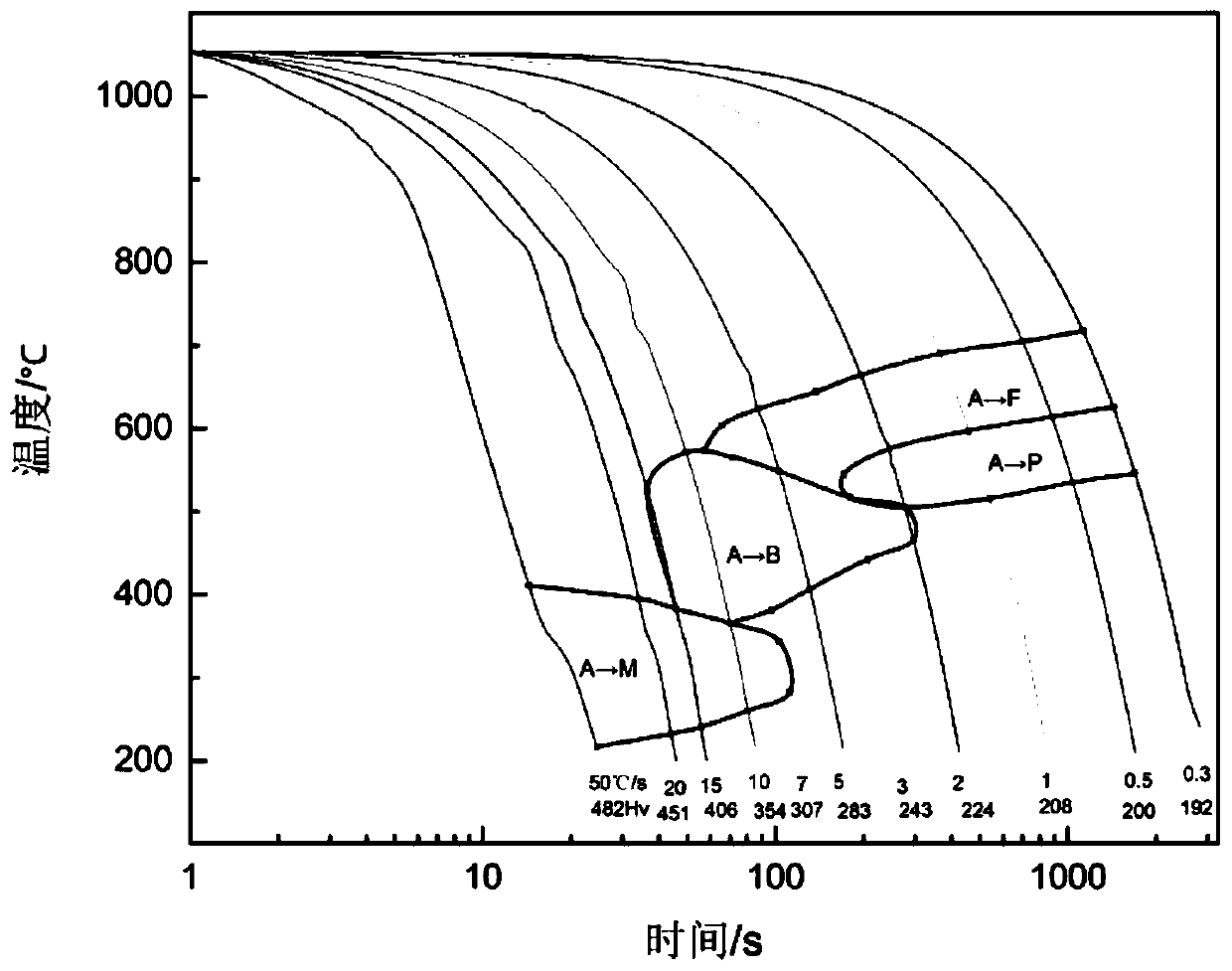

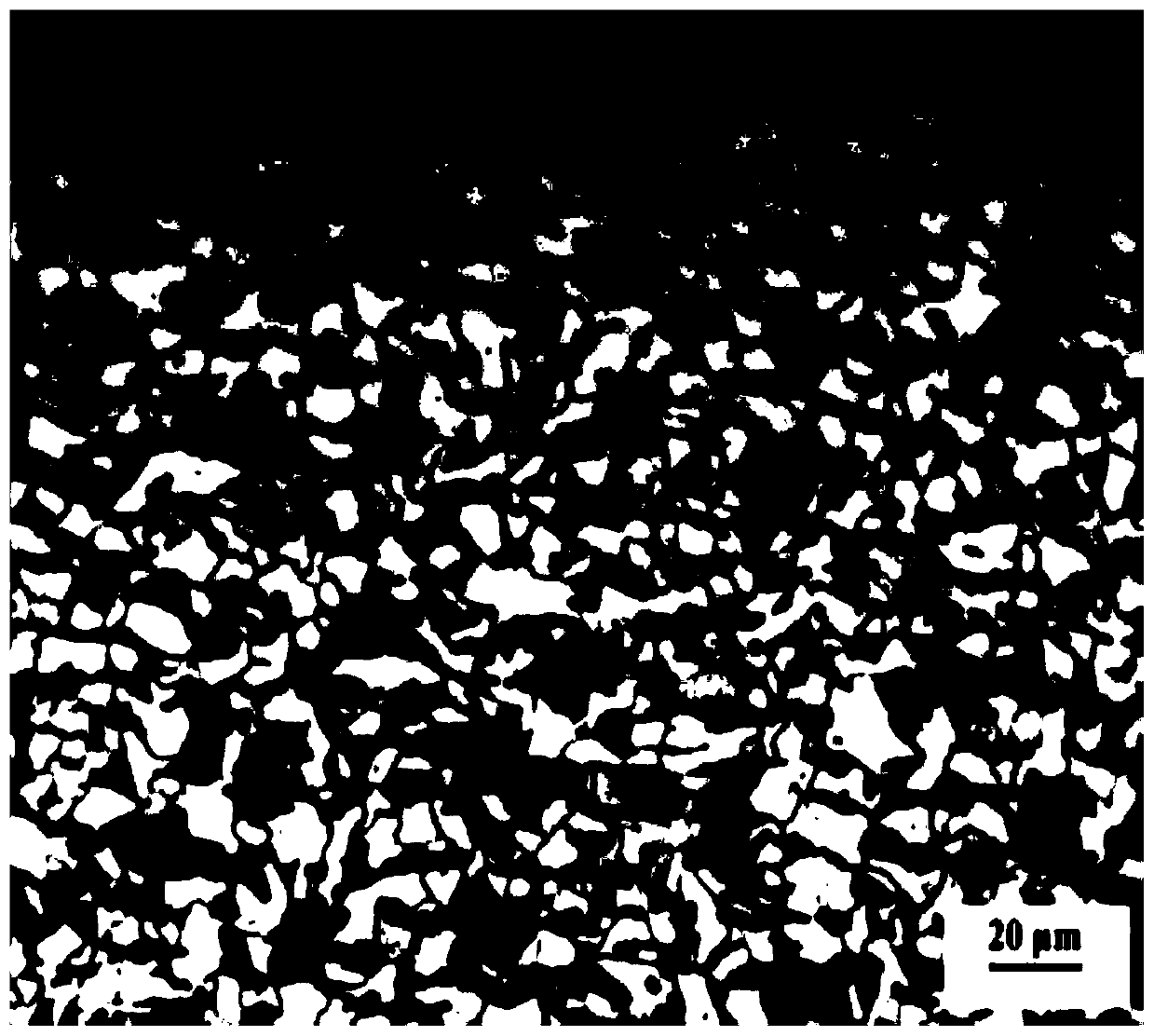

[0115] Combined with the above table data, Examples 1-9 show that when the Nb in the steel is 0.018%-0.025%, and the Mn is 1.10%-1.25%, and the content is low, a high heating and rolling temperature is used, although different production lines There is a difference of 20-40°C in the heating and rolling temperature, and the bainite content in the reinforced steel produced by different production lines is in the lower range of 4.5-7.0%, and there is no obvious difference.

[0116] Comparative examples 1 and 2 show that when the Nb in the steel is 0.025% to 0.035%, and the Mn is 1.45% to 1.55%, when the content is high, the bainite content in the steel is as high as 50 to 58.0% with high heating and rolling tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com